Device and method for purifying exhaust gas from industrial vehicle engine

a technology for industrial vehicles and exhaust gas, applied in mechanical equipment, machines/engines, electric control, etc., can solve the problems of combusting of particulates accumulated in filters, long time, and long time an engine is used continuously, and achieves good fuel efficiency and effective reprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

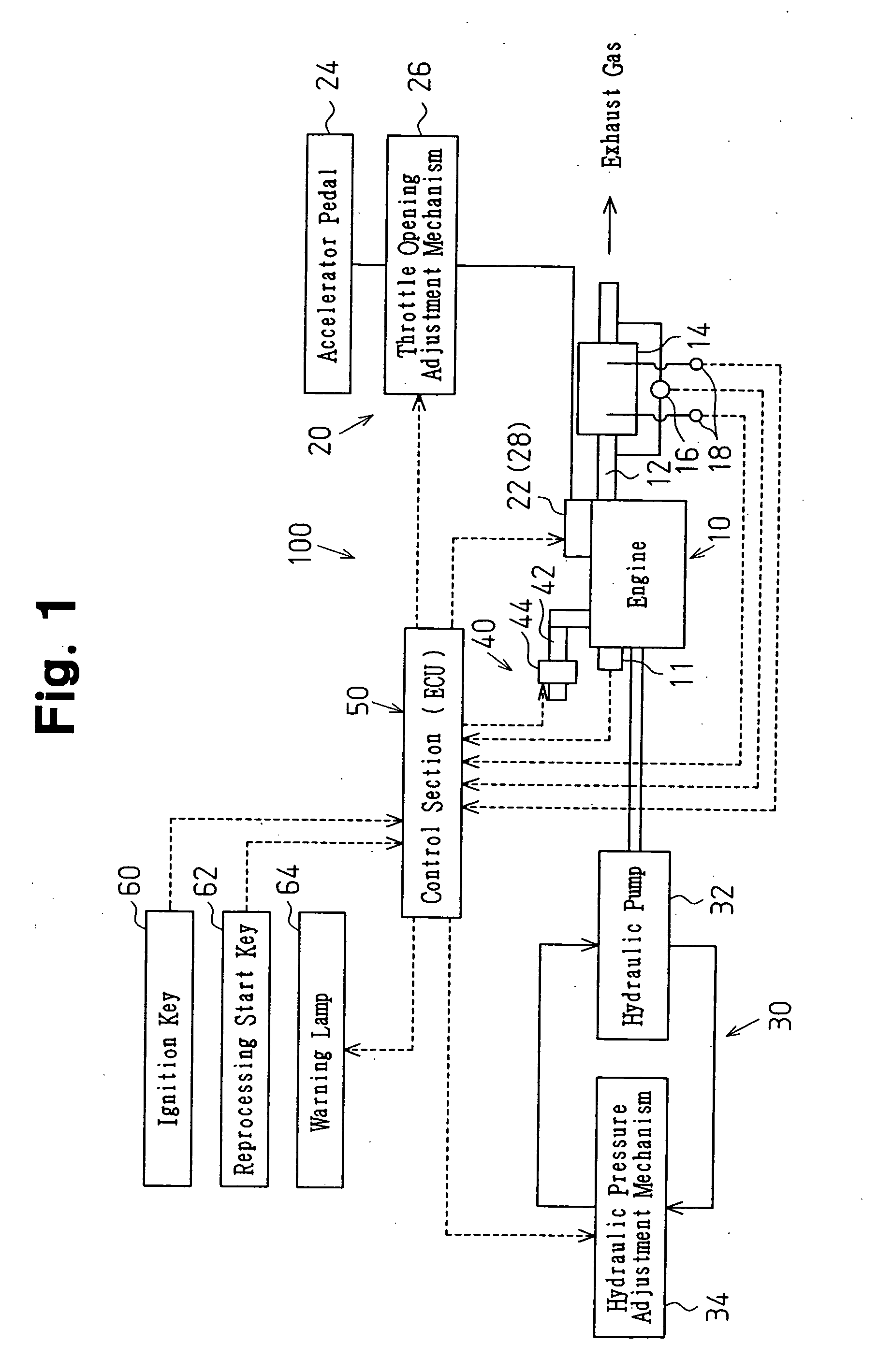

[0013] the present invention will be described below referring to FIGS. 1 to 3, and 5. It is to be noted that this embodiment is an explanation of an example of the present invention applied to the technology of a purifying process for the exhaust gas emitted from a diesel engine amounted on a forklift as an industrial vehicle.

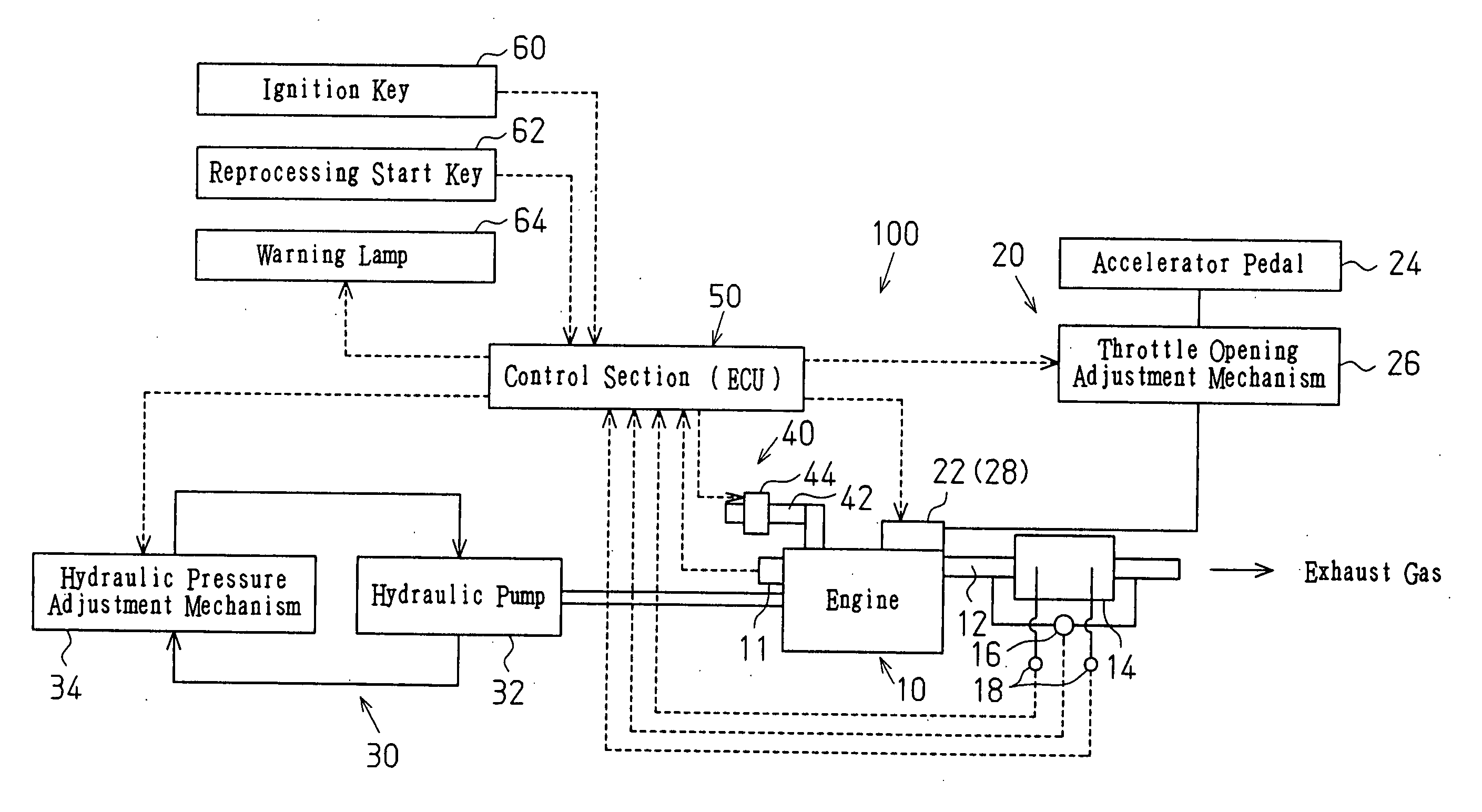

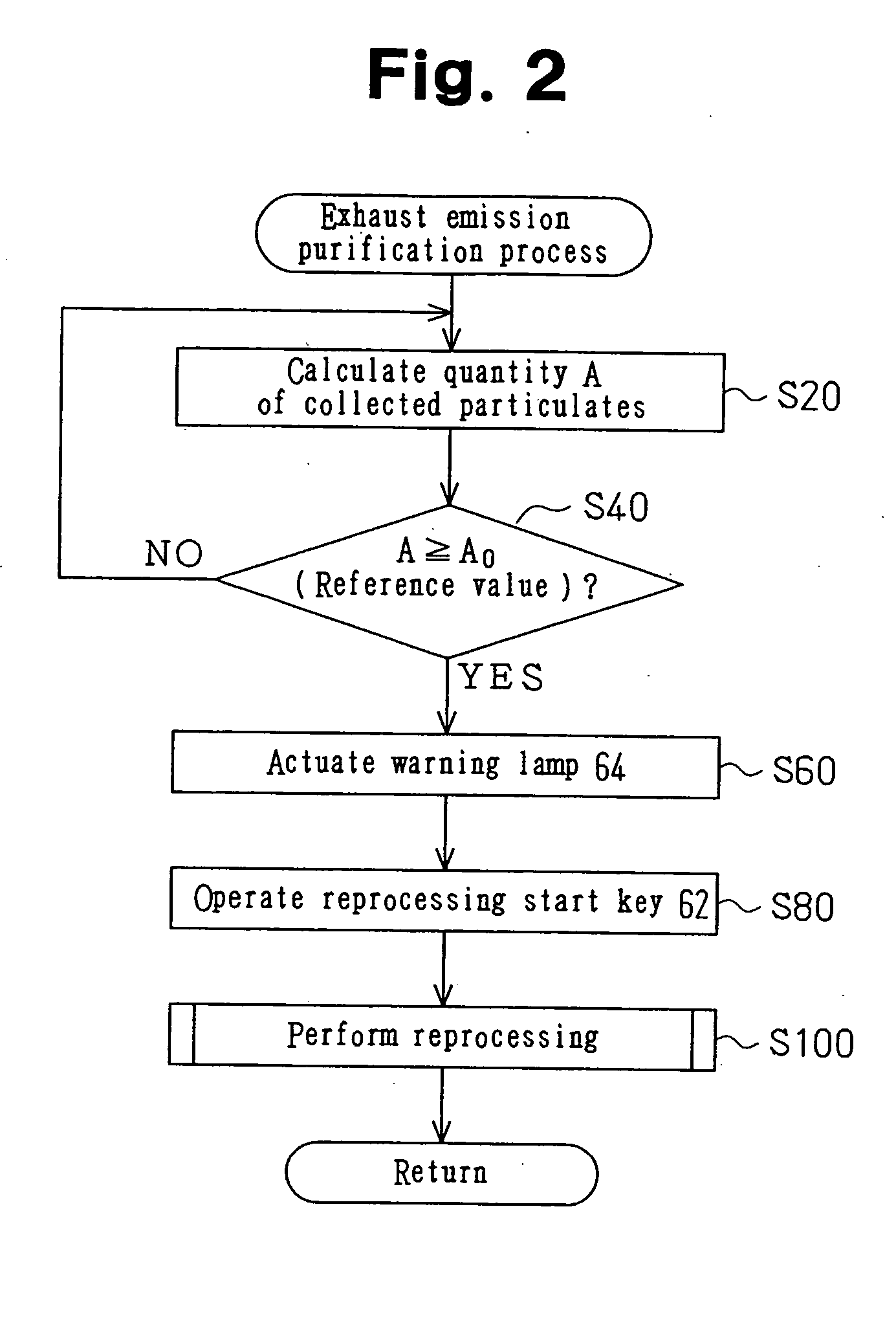

[0014] As shown in FIG. 1, a diesel engine 10 as an engine for an industrial vehicle is equipped with an exhaust emission purifying apparatus 100. The exhaust emission purifying apparatus 100 performs a purifying process for the exhaust gas emitted from the diesel engine 10. The exhaust emission purifying apparatus 100 includes a collection section 14 disposed in an exhaust passage 12 in a section downstream of the diesel engine 10, an injection amount adjustment section 20, an engine load adjustment section 30, an air intake restriction adjustment section 40, and a control section 50. It is to be noted that the diesel engine 10 is equipped with an engine spee...

second embodiment

[0031] Next, the present invention is explained in accordance with the flowchart shown in FIG. 4, referring to FIGS. 1 to 3. In the reprocessing shown in FIG. 4, steps S110 to S113, the same steps shown in FIG. 3, are performed. When the result of step S112 is YES, that is, if the value of the throttle opening degree M is determined to be equal to or greater than the second reference value, the process proceeds to step S120.

[0032] In step S120, the control section 50 detects the differential pressure ΔP at the collection section and compares such detected value with a third reference value BkPa. If the result of step S120 is YES, that is, if such detected differential pressure ΔP is determined to be equal to or less than the third reference value, in other words, if the amount of accumulated particulates at the collection section 14 is less than the predetermined control value, the process proceeds to step S122.

[0033] In step S122, the control section 50 detects the outlet temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com