Exhaust system for open front fireplace

a technology for exhaust systems and open fireplaces, which is applied in the field of exhaust systems for open fireplaces, can solve the problems of unreachable ventilation, waste products such as carbon monoxide, reaching too high levels within the structure, and occupants could die, and achieve the effect of promoting more efficient heat retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

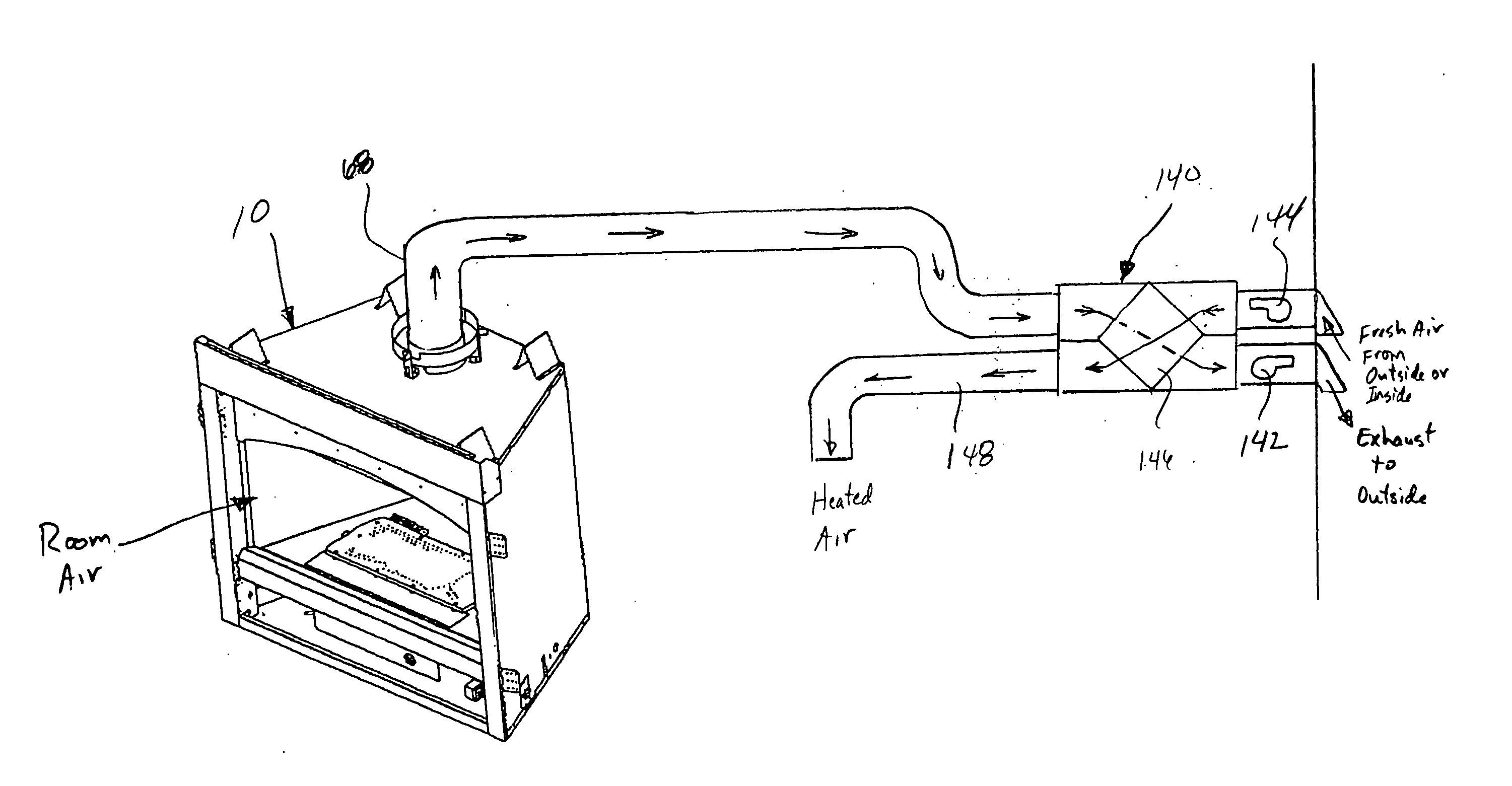

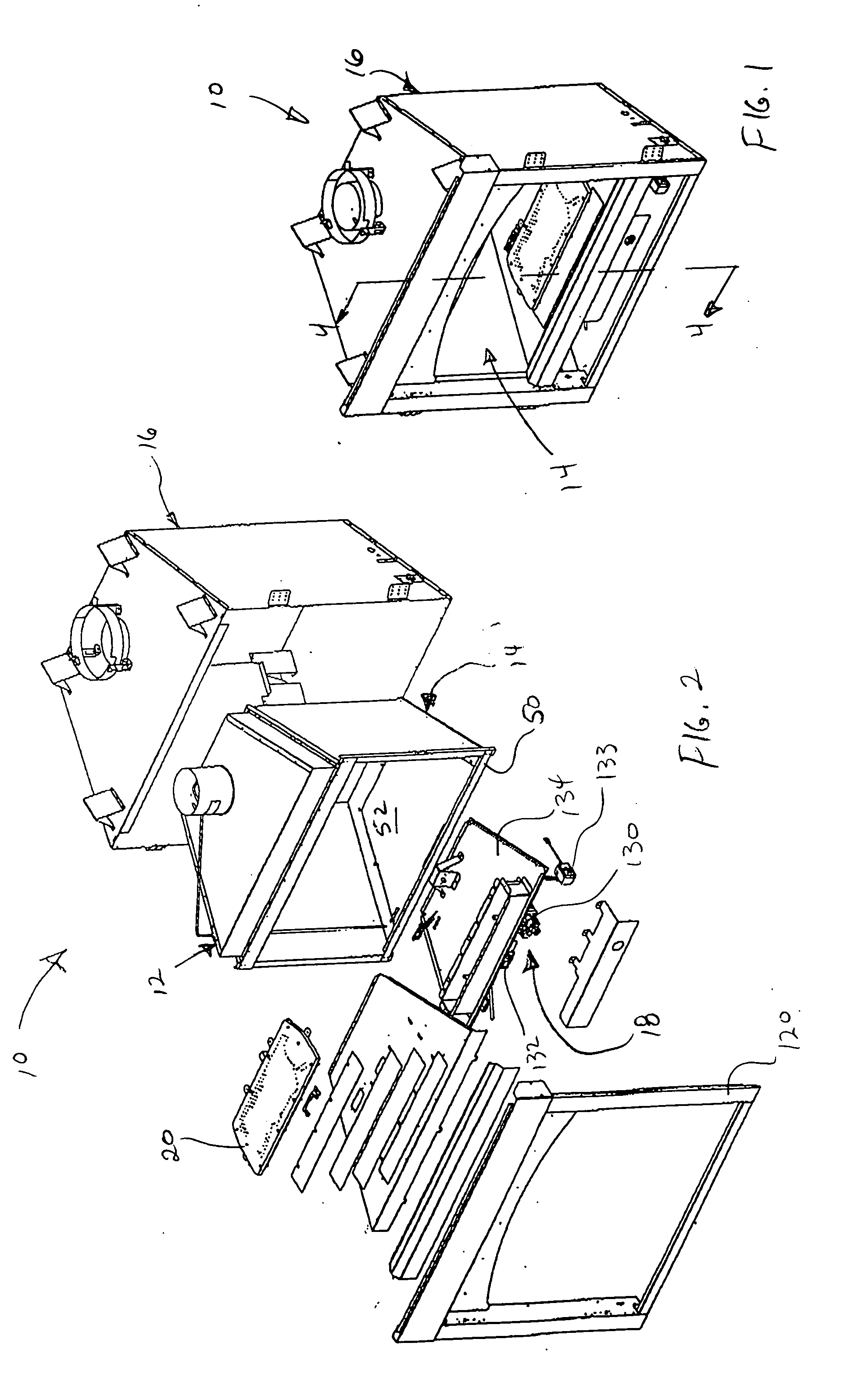

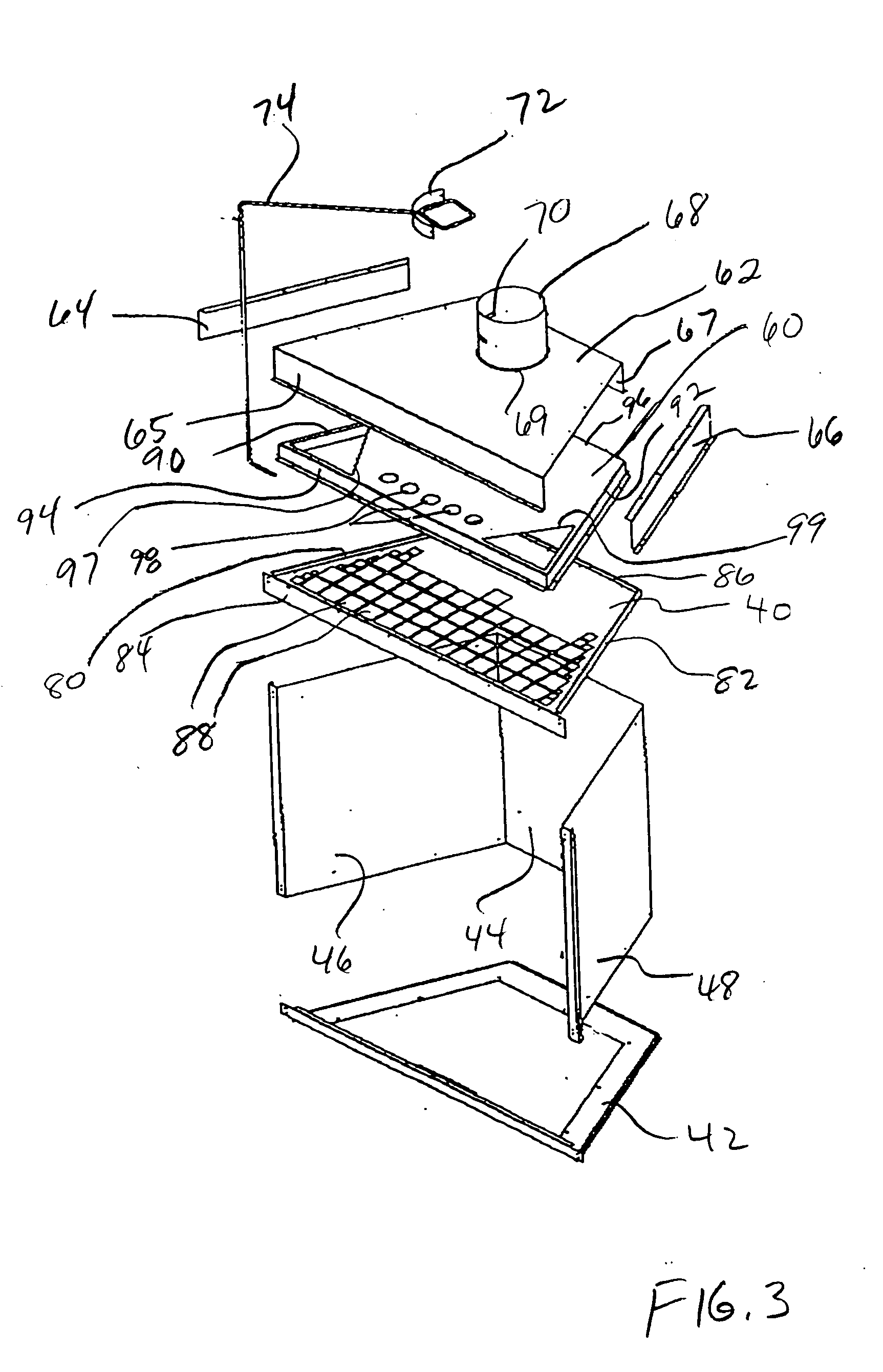

[0022] The present invention generally relates to heating appliances, and more particularly relates to a venting system for a heating appliance. The venting system of the present invention may be useful for venting waste products from an open front combustion chamber, promoting more efficient retention of heat generated by the heating appliance, and providing a safety system to ensure the waste products produced are not released into a living space in proximity to the heating appliance. Although the present invention may be especially useful in a heating appliance with an open front combustion chamber, many principles of the present invention may be applied to heating appliances with a sealed combustion chamber or heating source enclosure.

[0023] As used herein, the term “open front fireplace” refers to any fireplace or heating appliance with an open front for the free flow of room air into the combustion chamber or other heating source enclosure of the appliance. The terms “combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com