Portable vaporizer

a vaporizer and portable technology, applied in the field of portable vaporizers, can solve the problems of not completely serving this purpose, cumbersome devices, and cumbersome devices utilizing flames as heat sources, and achieve the effects of convenient replacement, convenient and efficient operation, and convenient us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

A) General Description

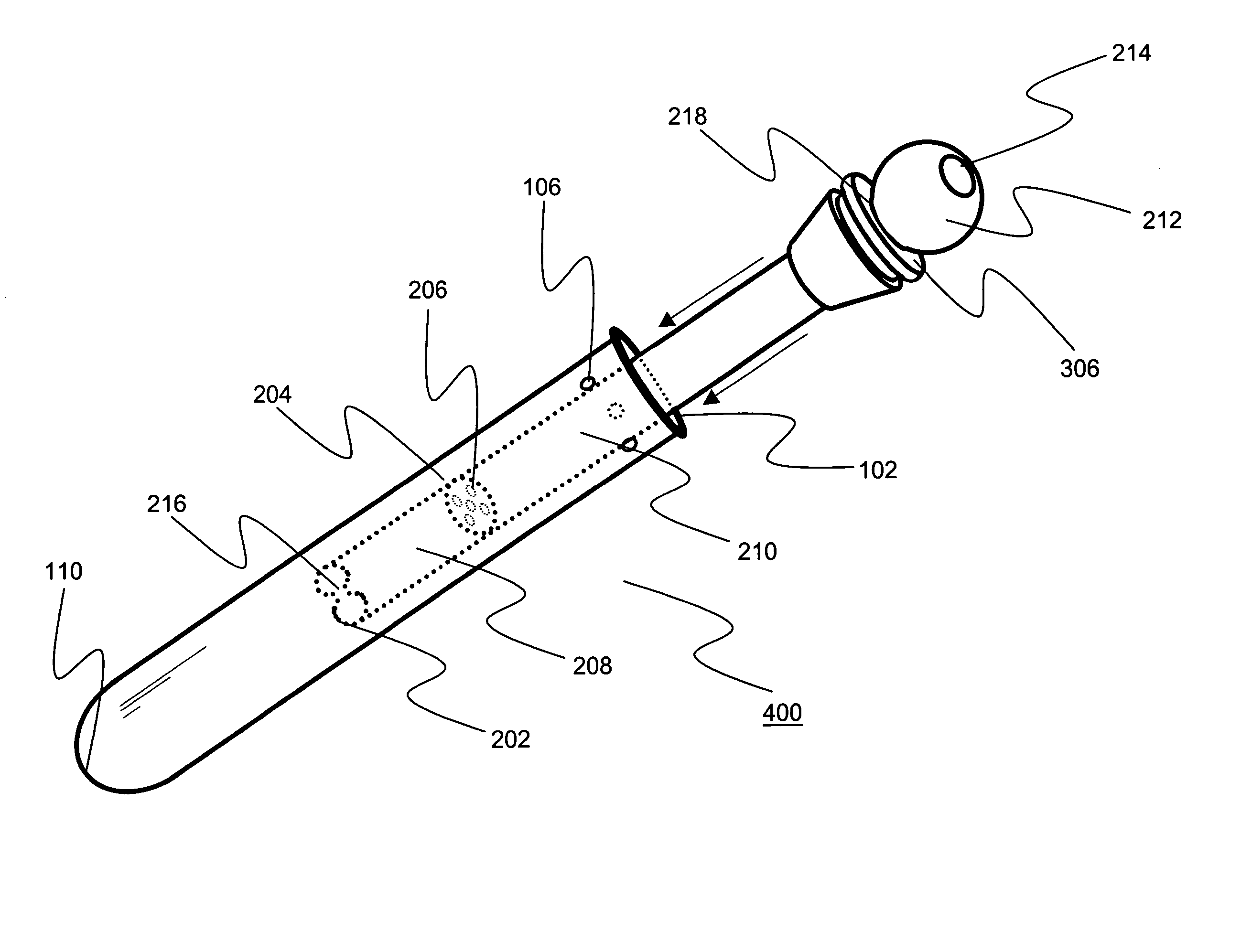

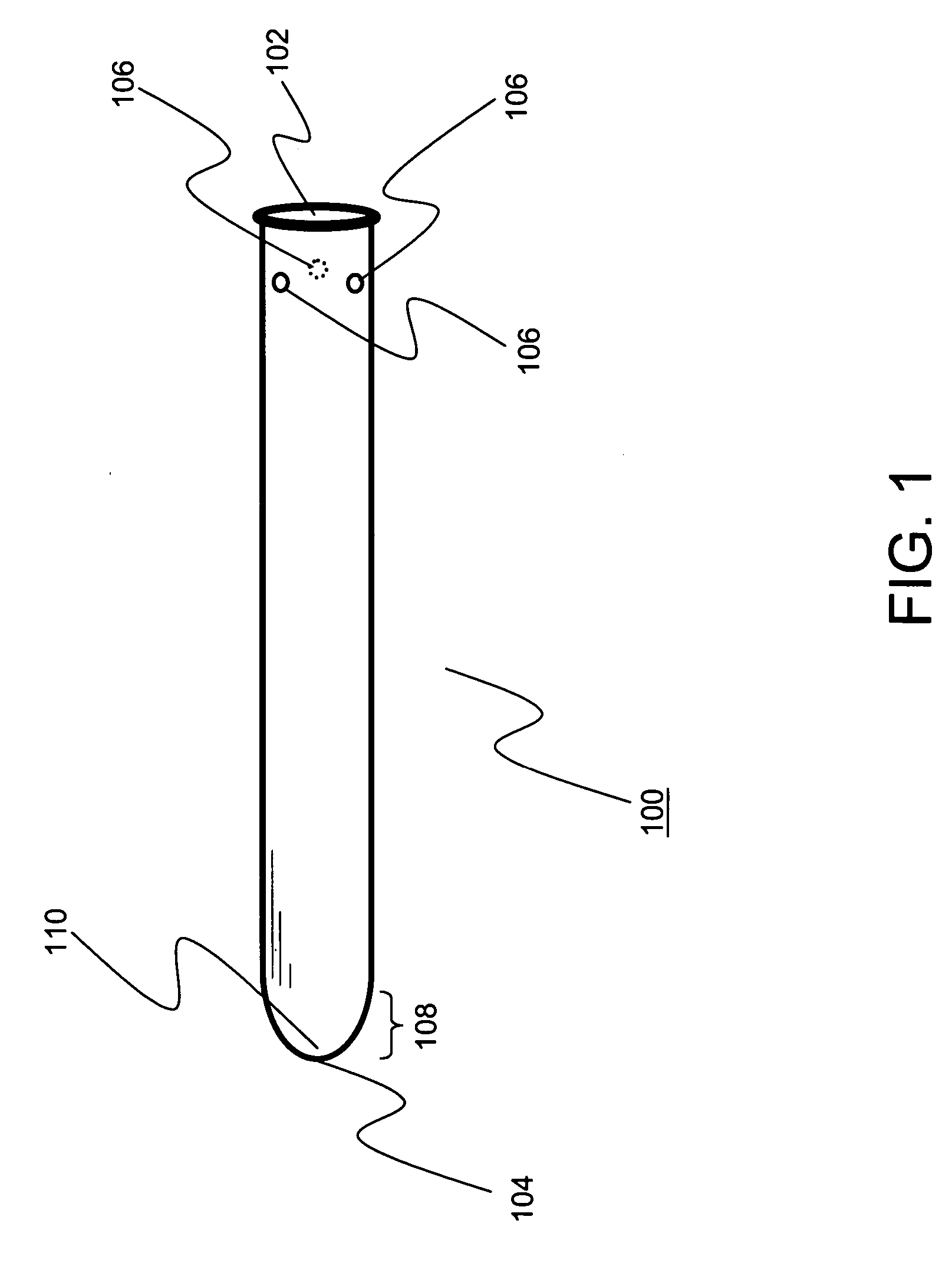

[0092] In one aspect, the present invention teaches a portable vaporizing device, the device generally comprising an outer vessel and an inner vessel held together by a fastener. The invention also optionally comprises an outer insulating wrap.

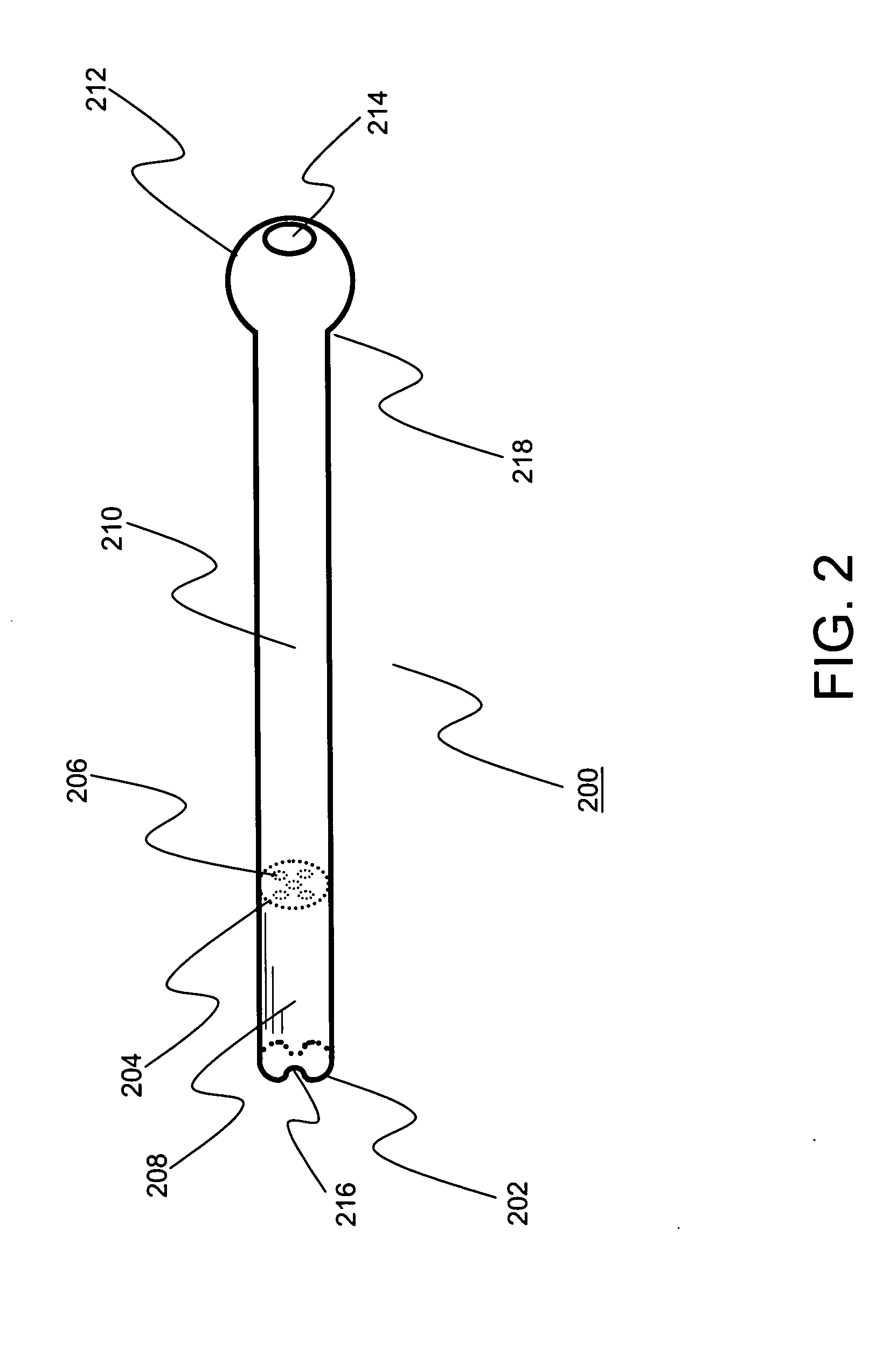

[0093] The outer vessel has a closed distal end and an open proximal end. The inner vessel has an open proximal end as well as an open distal end. The inner vessel also has a partition within it, spanning the inner cross-sectional area of the vessel. The partition divides the inner volume of the inner vessel into two chambers, a vaporization chamber distally and a drawing chamber proximally. The partition also has screening holes through it to allow air to be drawn from the vaporization chamber through the partition into the drawing chamber, while keeping the vaporizable substance in place inside the vaporization chamber, the partition thus functioning essentially as a screening mechanism.

[0094] When the device is assem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com