Process for manufacturing reproduction with a luminescence effect and reproduction manufactured by the implementation of the process

a technology of luminescence and manufacturing process, which is applied in the field of manufacturing reproductions with luminescence effects, can solve the problems of limited luminescence characteristics, limited brightness and duration of photoluminescent pigments, and inability to produce reproductions with very high resolution and very sharp images. , to achieve the effect of high quality of detail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

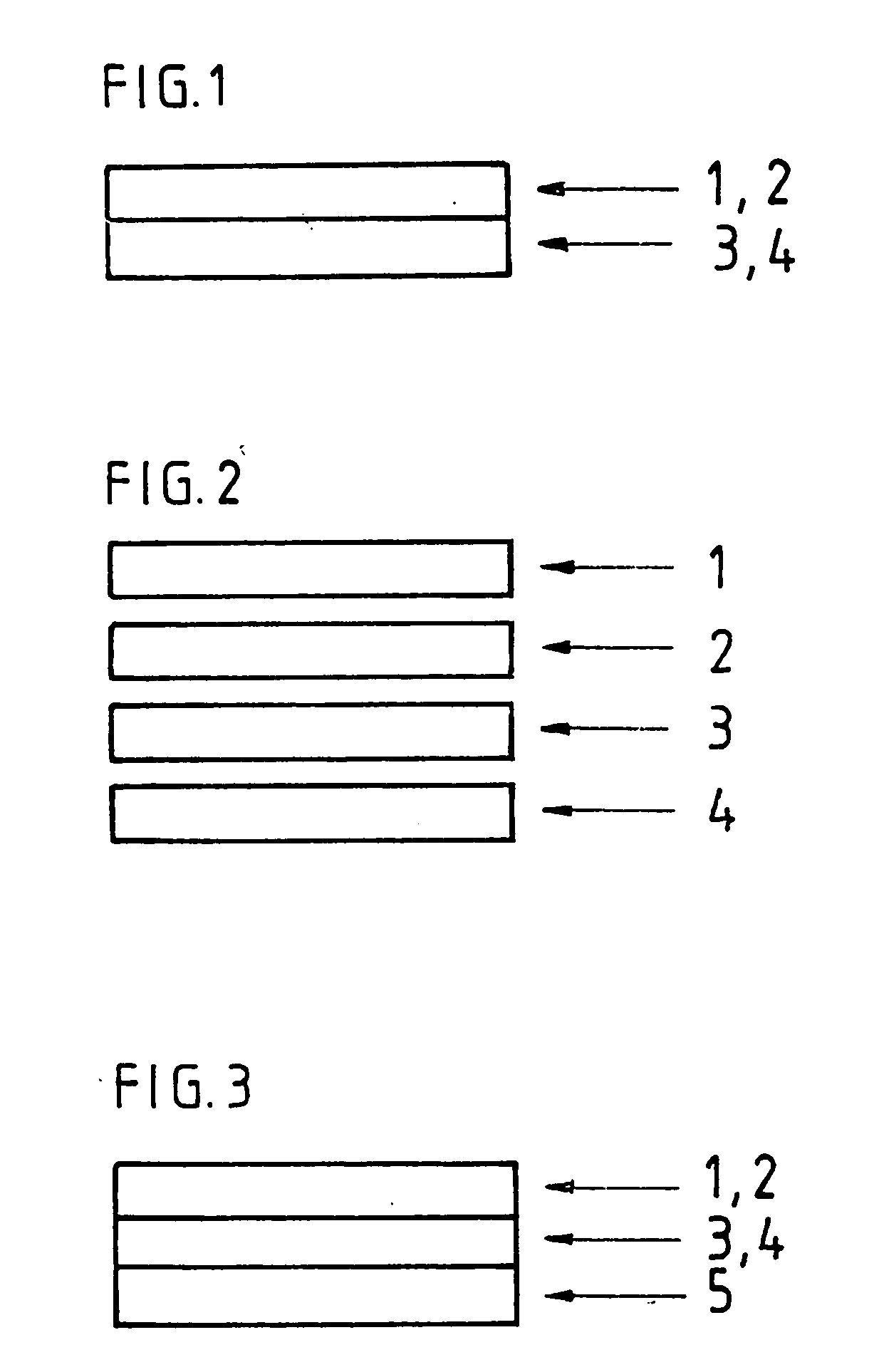

[0032] In the simplest embodiment of the invention, an image 2 is reproduced on a transparent carrier 1 and a film 4 incorporating a luminescent, and more especially a photoluminescent, product is applied to the carrier 1, either on the same side as the printed image or on the other. A filter 3 in the form of a film allowing the effects of the color of the photoluminescent material to be moderated is inserted between the carrier 1 and the film 4.

[0033] More precisely, filter 3 is a translucent material that desaturates the color of the luminescent layer by way of its light scattering capability. Desaturation of color is equivalent to the adding of white to a color thereby making the color less intense. Light which passes through the filter 3 is scattered uniformly thereby giving rise to a white haze, is then reflected off of the luminescent layer 4 and then passes through filter 3 again on its way to the eye of the viewer. Additional scattering of the light occurs during this secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com