Wooden material board, in particular flooring panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

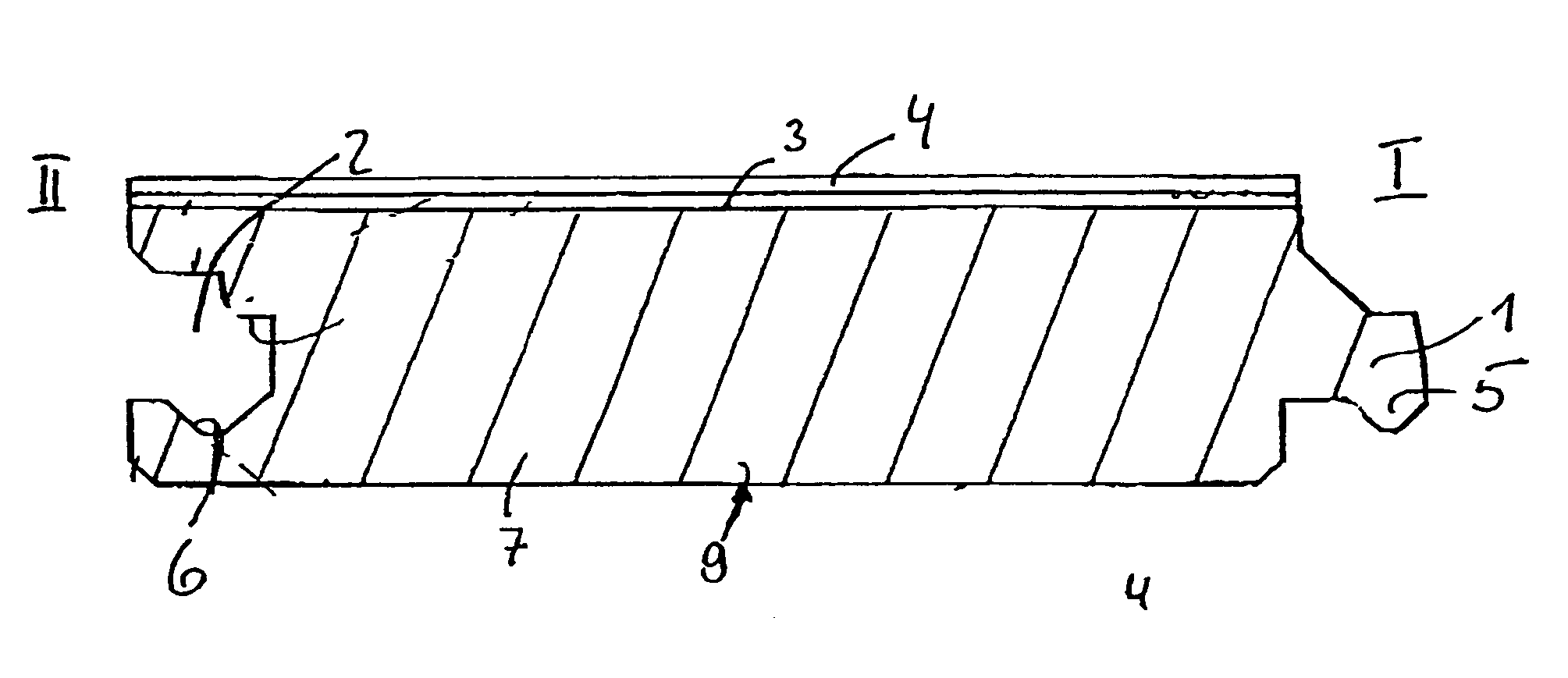

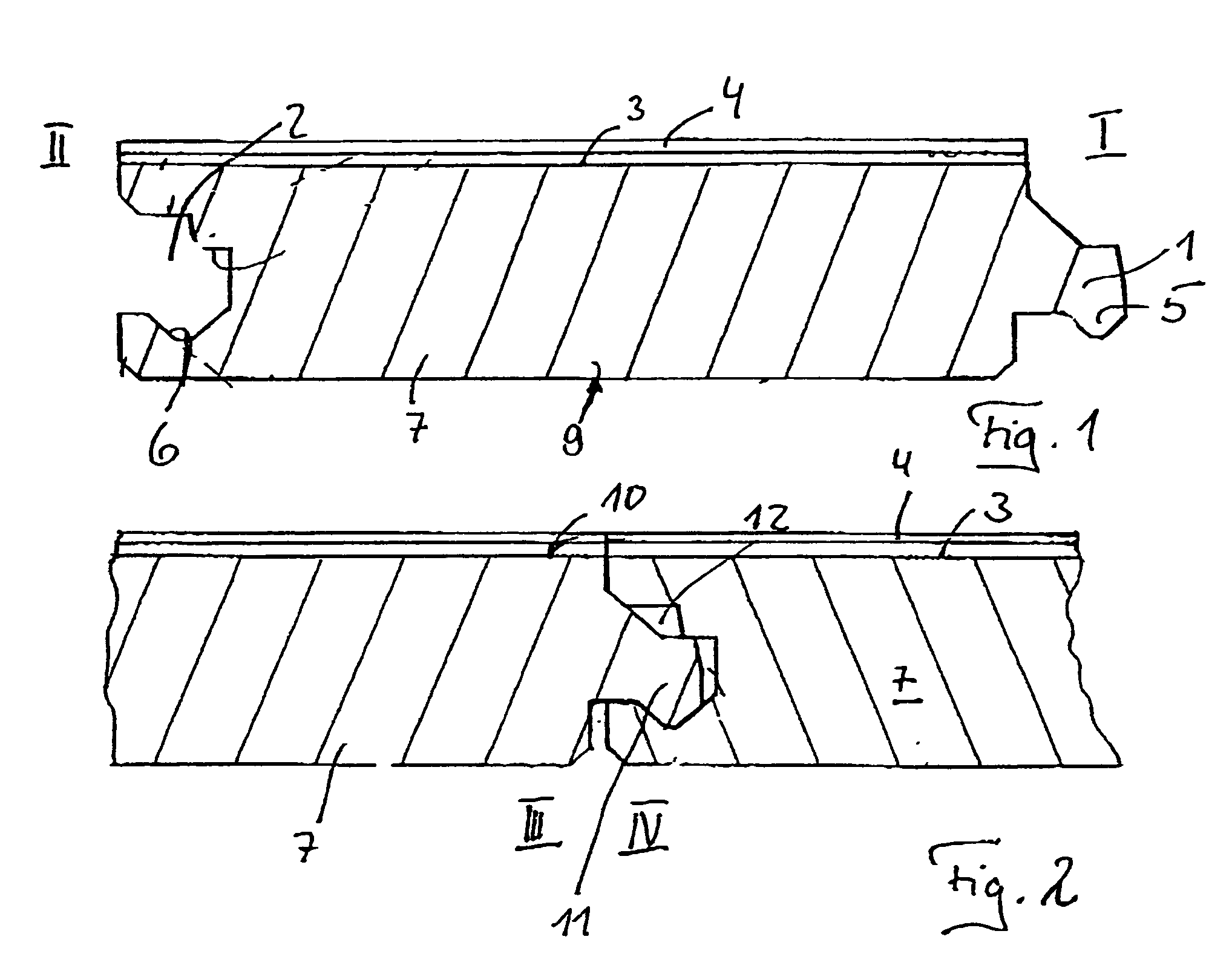

[0021] The flooring panel 7 has a core of wooden material, preferably HDF or MDF. On one longitudinal edge I and one transverse edge III, the panel 7 is provided with a tongue 1, 11 and, on the opposite side edge II, IV, is provided with a groove 2, 12 corresponding thereto. A pattern, for example a wood grain, is printed directly onto the top side 10. An elastic varnish layer 3 is applied to the decoration and this is in turn covered by an inelastic varnish layer 4, into which corundum particles can be scattered. The varnishes of the varnish layers 3, 4 are UV-curable. On the underside 9, if necessary, a counteracting layer is provided (not shown), which prevents the panel (7) bending as a result of the tensile forces occurring because of the varnish layers 3, 4. The tongues 1, 11 are provided with locking means 5, which correspond to the locking means 6 provided in the groove 2 and lock the panels against displacement in the transverse direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com