Power tool

a power tool and power technology, applied in the field of power tools, can solve the problems of increasing manufacturing costs and increasing the demand for low noise of power tools, and achieve the effect of sufficient air volume and low nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

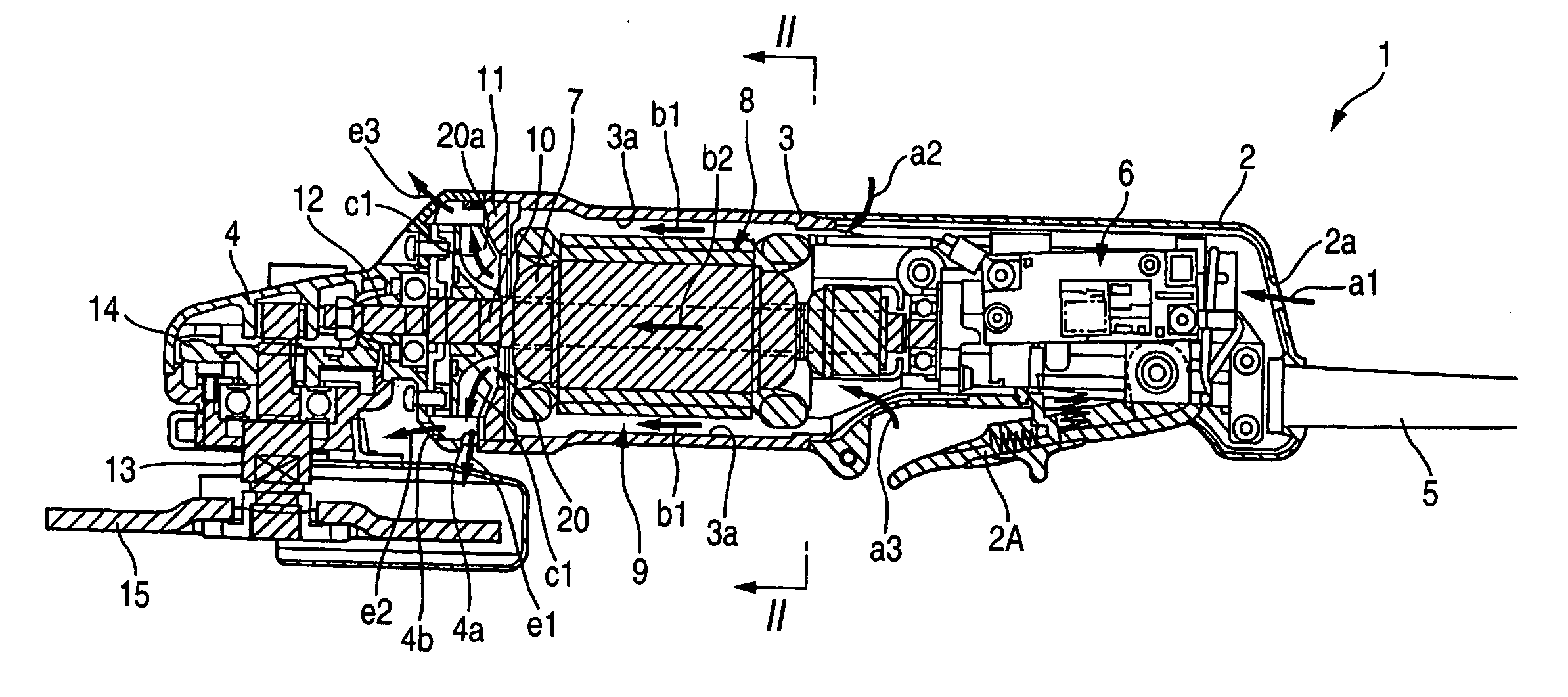

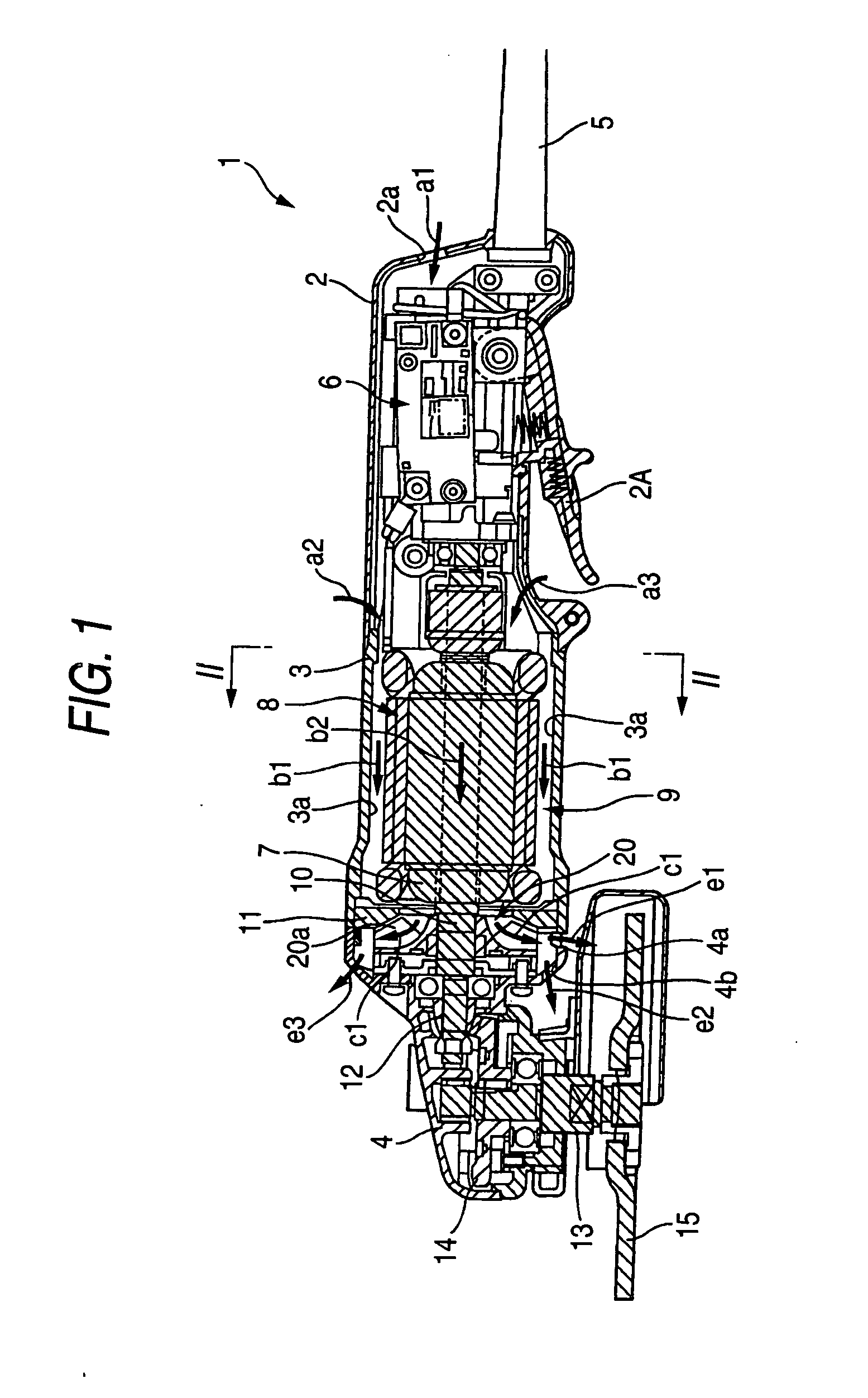

[0037] Referring to FIG. 1, a description will be given of a power tool according to one embodiment of the invention is applied to a grinder (disc grinder).

[0038]FIG. 1 shows an overall structure of a disc grinder 1. If it is assumed that the left-hand side in the drawing is a front end, a resin-made handle portion 2, a resin-made motor housing 3, an aluminum alloy-made gear cover 4 are consecutively connected in that order from the rear side, thereby constituting a housing. Spaces defined in the respective interiors of the handle portion 2, the motor housing 3, and the gear housing 4 communicate with each other. A power supply cable 5 is attached to the handle portion 2, and a switch mechanism 6 is incorporated therein. The switch mechanism 6 is provided with a lever 2A which can be operated by a user. The power supply cable 5 connects the switch mechanism 6 to an external power source (not shown), and the connection and disconnection between the switch mechanism 6 and the power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com