Object lens producing device and producing method

a technology of producing device and producing method, which is applied in the direction of instruments, recording information storage, disposition/mounting of heads, etc., can solve the problems of inability to accurately condensate light beam radiated from light source on the signal recording surface, and it is extremely time-consuming to adjus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Referring to the drawings, preferred embodiments of the present invention will be explained in detail.

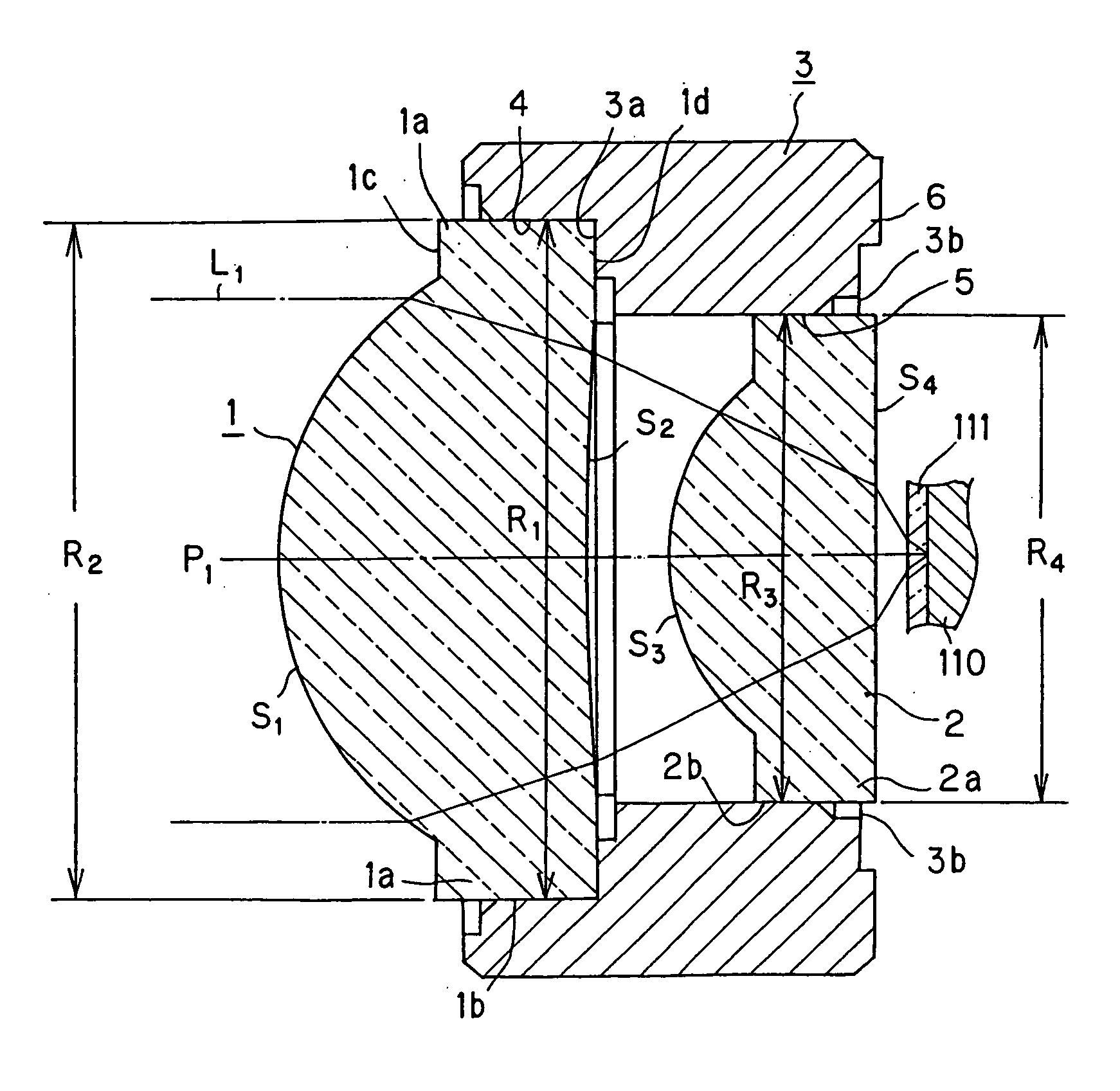

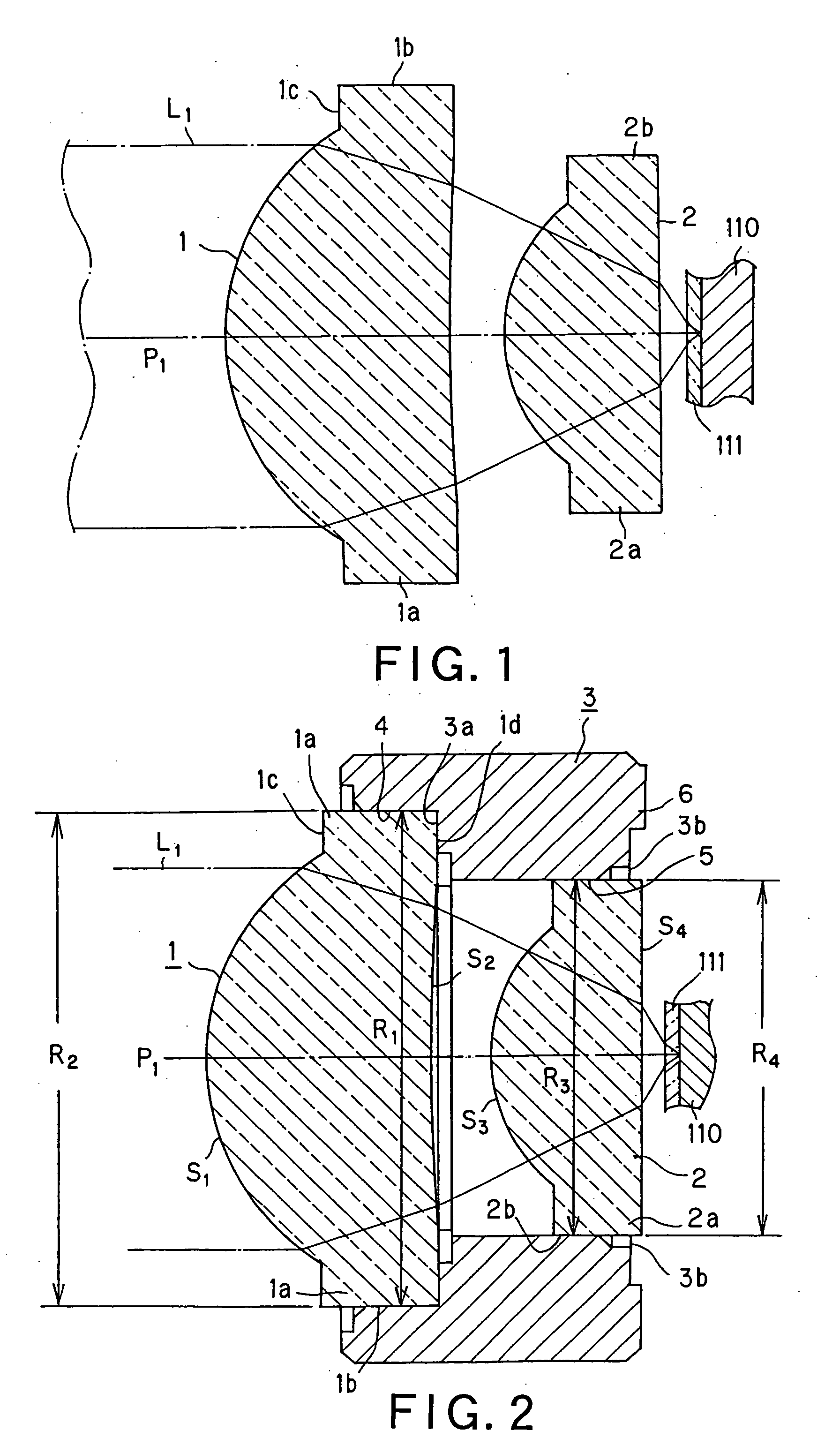

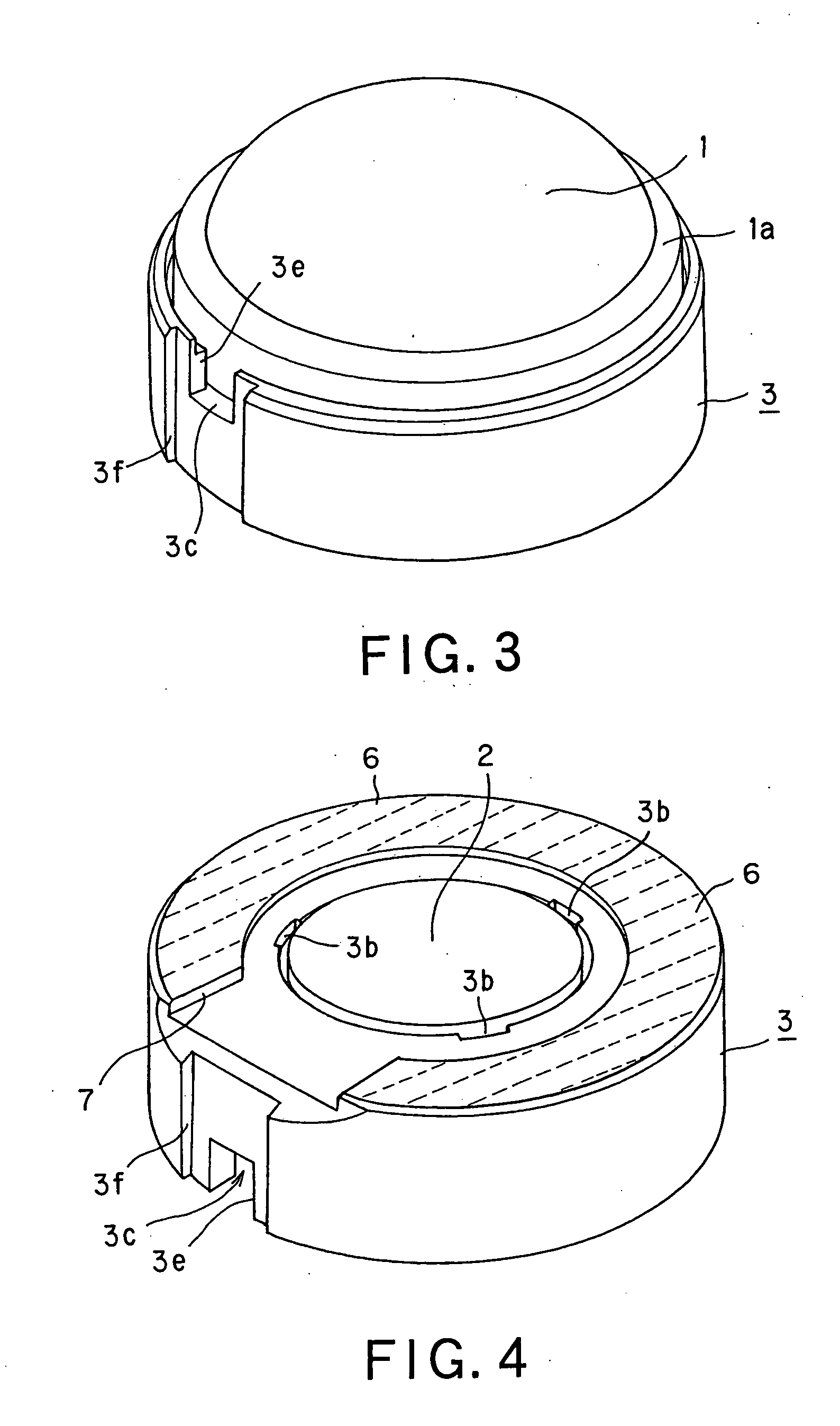

[0072] An objective lens unit of the present invention is made up by plural lenses each having a numerical aperture (NA) of 0.7 or larger. Specifically, the objective lens unit is made up by a double-lens set of two lenses 1, 2, and has a numerical aperture (NA) of 0.85, as shown in FIG. 1.

[0073] The objective lens unit of the present invention is built into an optical pickup device having a light source radiating the light beam with a center wavelength of 405 nm. That is, the objective lens unit according to the present invention is mainly used for condensing the light beam having a center wavelength of 405 nm.

[0074] In the following explanation, it is assumed that the objective lens unit has an effective diameter of 3 mm. Specifically, the manufacturing method for the objective lens unit of the present invention is the method for assembling an objective lens unit. An obj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| center wavelength | aaaaa | aaaaa |

| effective diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com