Inspection system and method for providing feedback

a technology of inspection system and feedback, applied in the direction of adaptive control, image enhancement, instruments, etc., can solve the problems of direct impact on the performance of the classifier, labor-intensive manual adjustment process, time-consuming and error-prone, etc., and achieve the effect of improving reliability and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

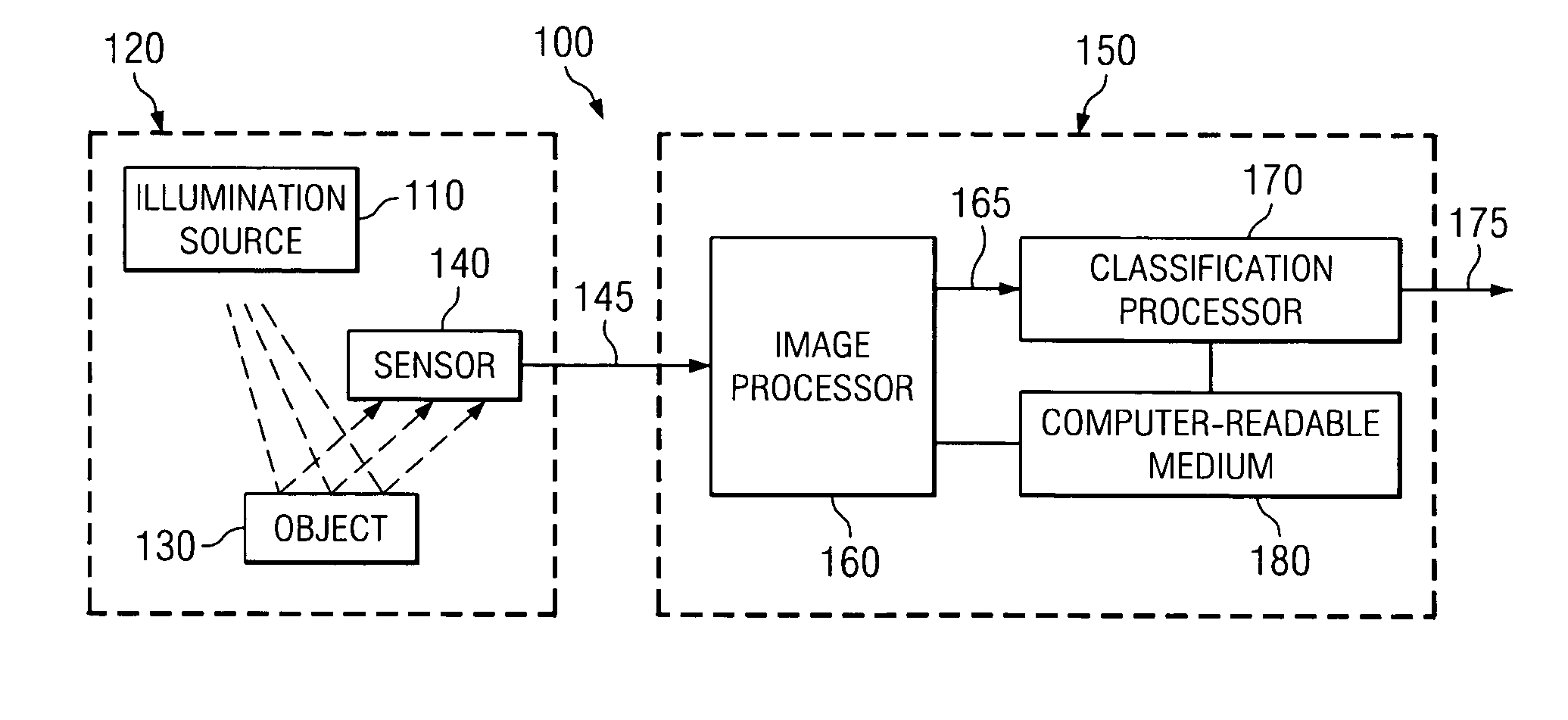

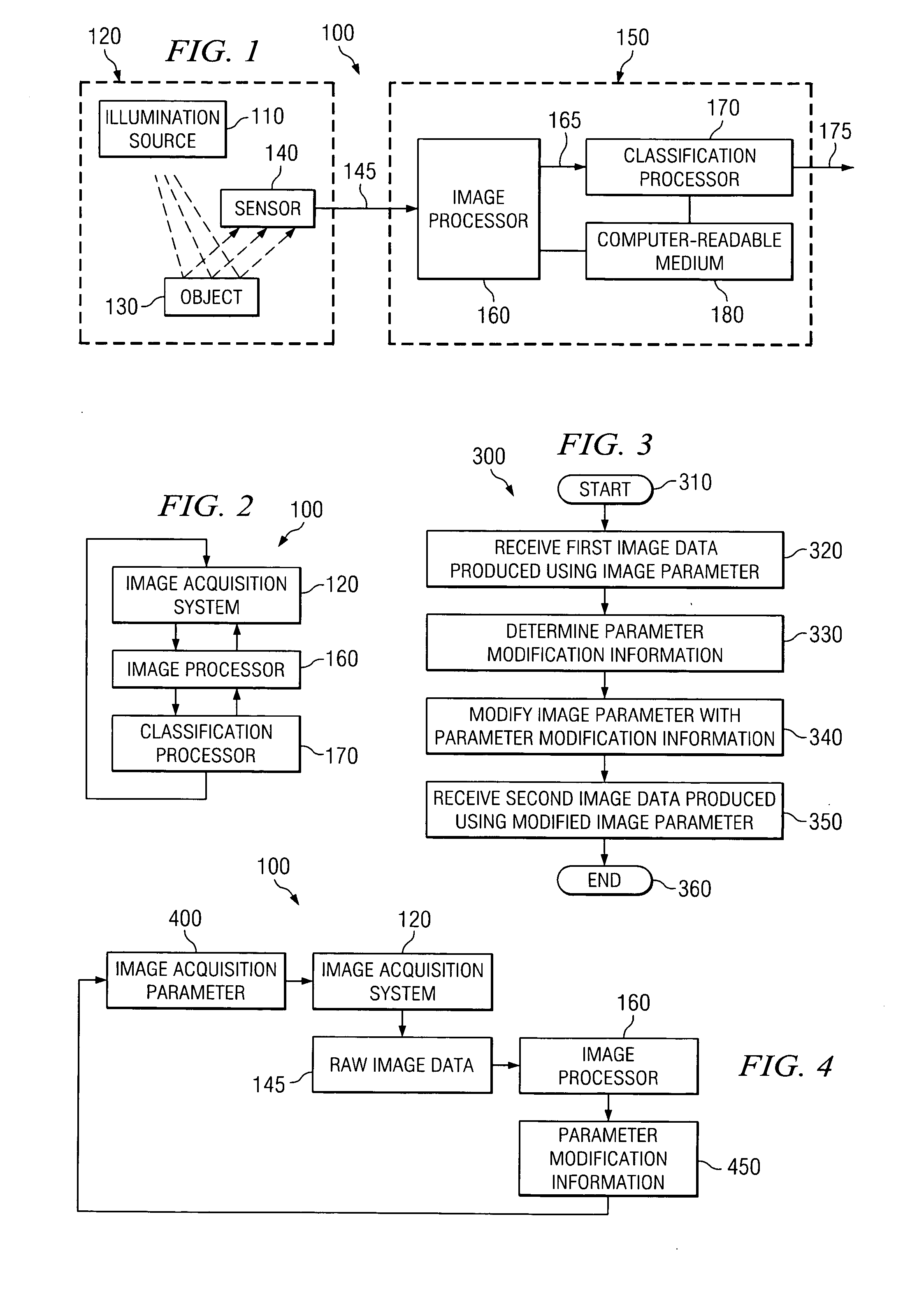

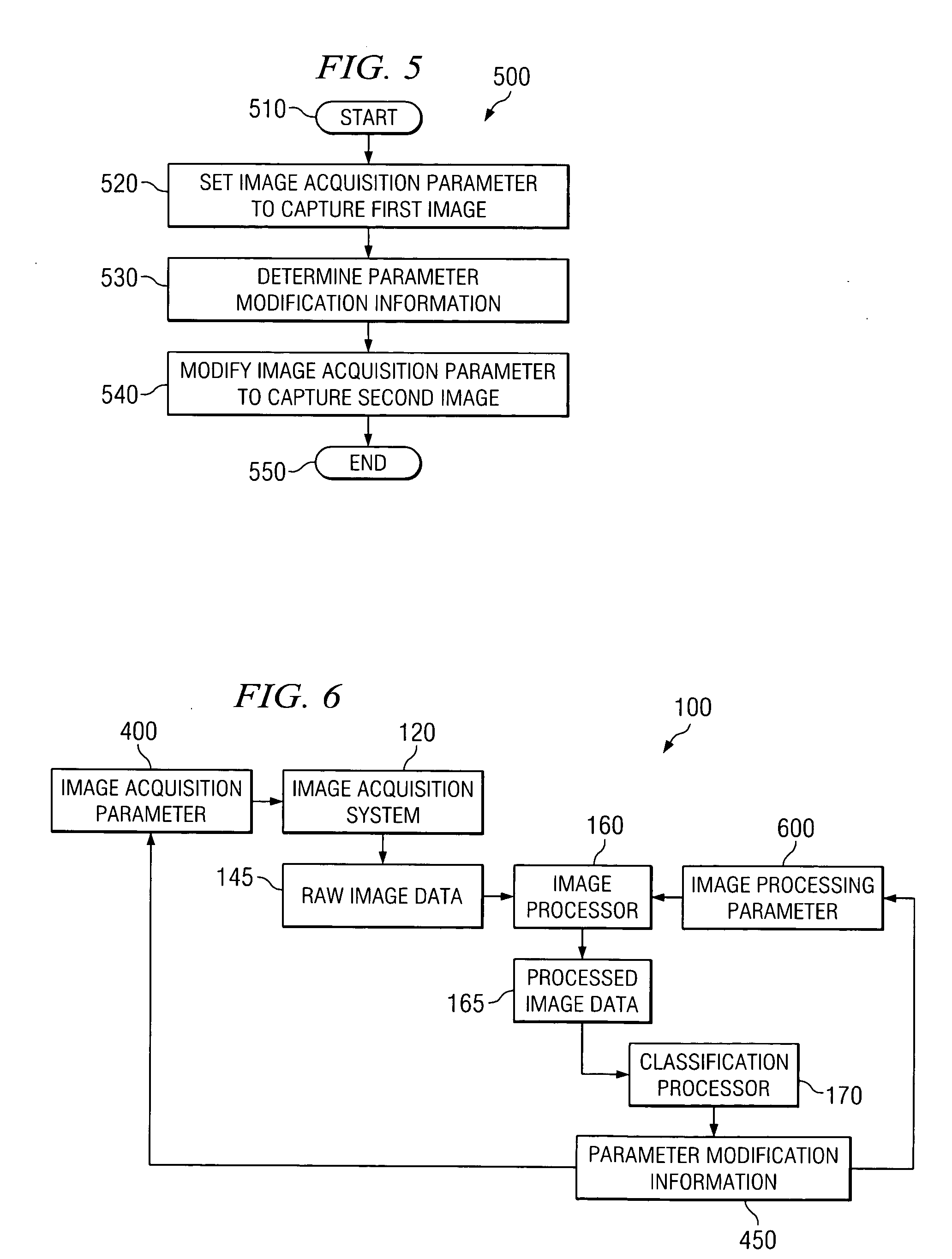

[0025]FIG. 1 is a simplified illustration of an inspection system 100 capable of providing internal feedback to automatically make adjustments in real time. The inspection system 100 can be, for example, an automated printed circuit board inspection system, other manufacturing inspection system, luggage inspection system used in airport security or other type of inspection system. The inspection system 100 includes an image acquisition system 120 having an illumination source 110 for illuminating an object 130 and a sensor 140 including a plurality of pixels for capturing an image of the object 130 and producing raw image data 145 representing the image of the object 130. In one embodiment, the illumination source 110 is an X-ray source that produces a beam of X-rays and projects the X-ray beam through the object 130 to the sensor 140. In another embodiment, the illumination source 110 is a light source that emits light towards the object 130. The light is reflected off the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com