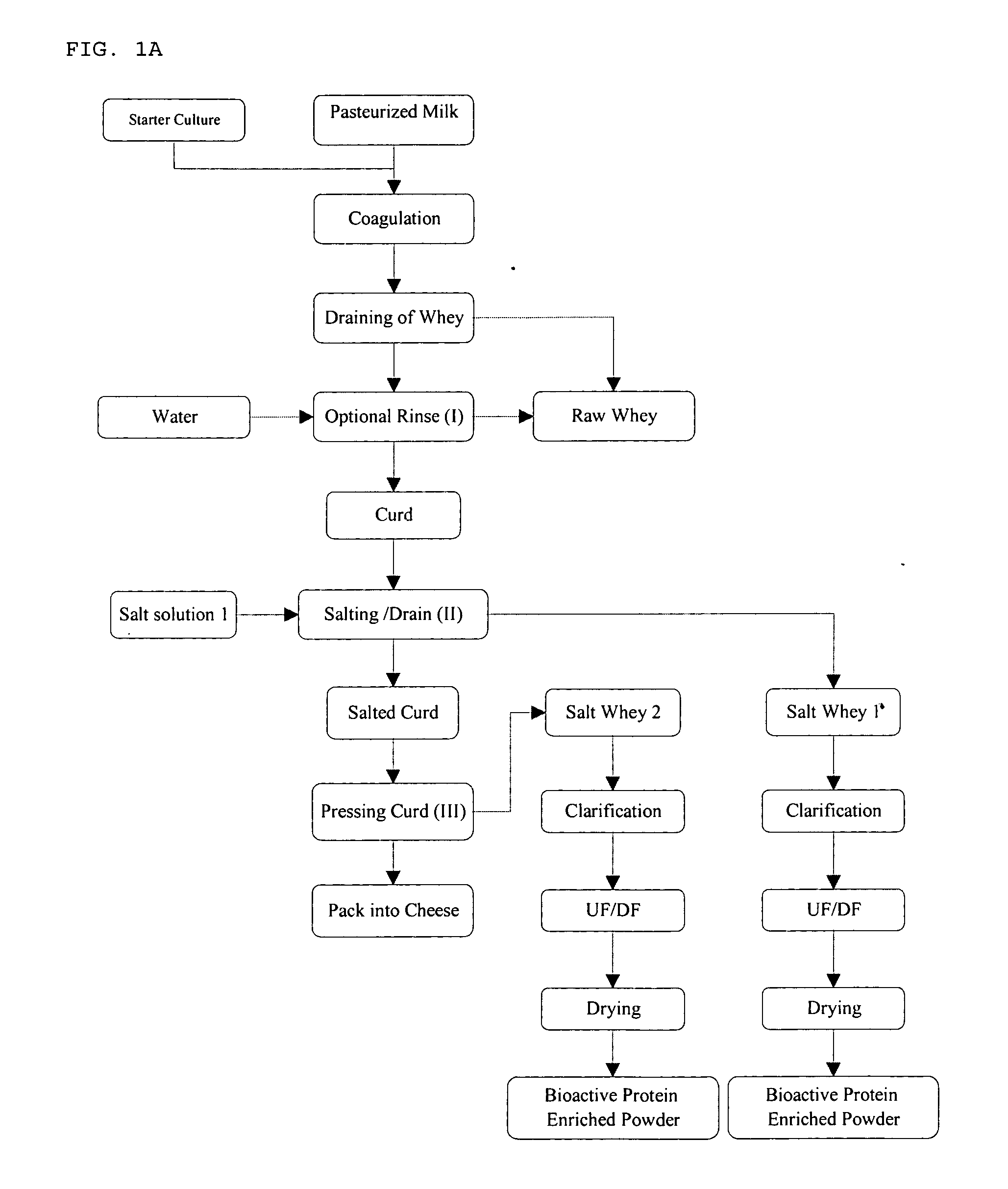

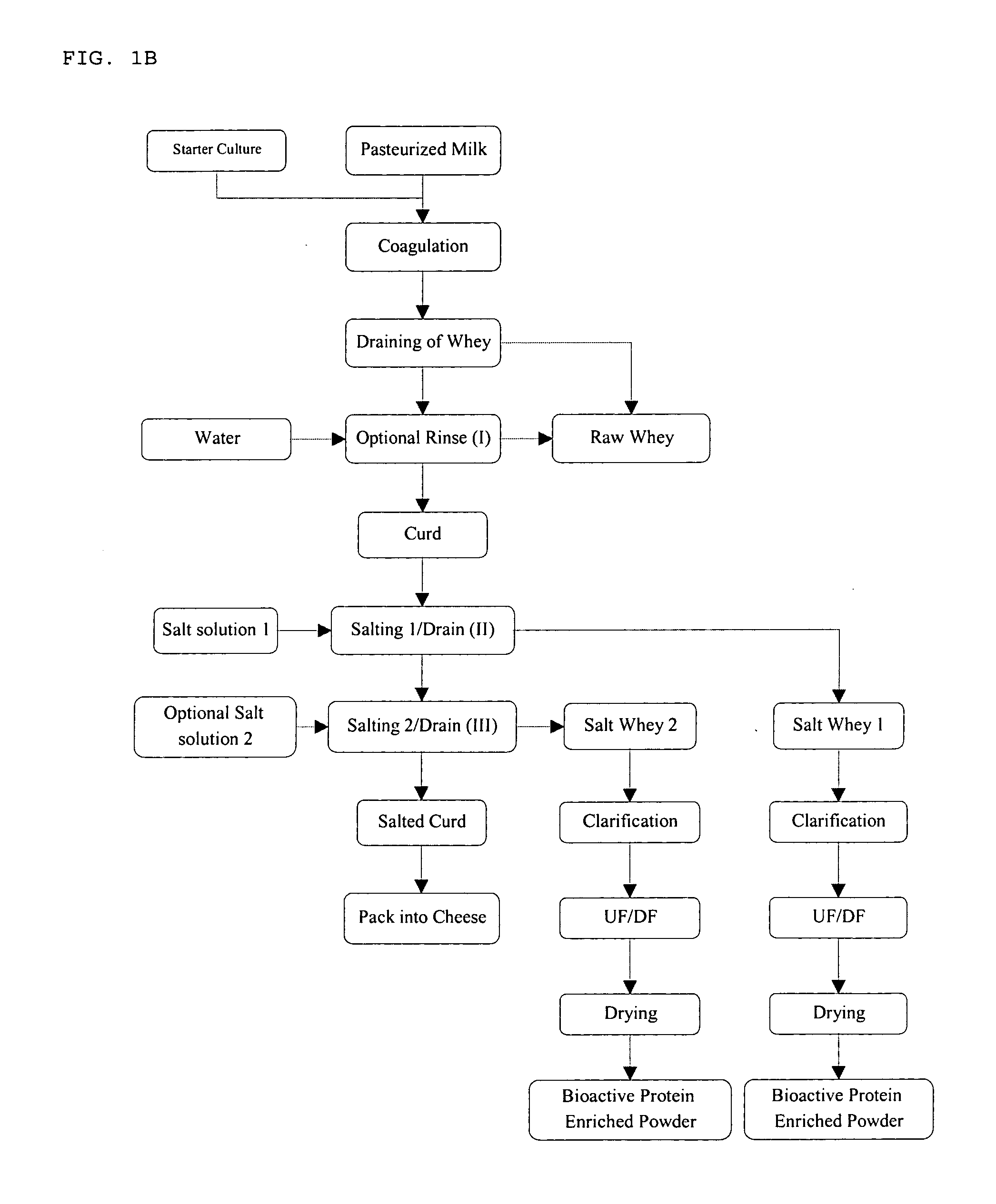

Process for preparing bioactive protein-enriched whey products

a technology of bioactive proteins and whey, which is applied in the field of process for preparing bioactive protein-enriched whey products, can solve the problems of high cost of isolation and purification of these bioactive proteins, and hinder their commercial utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0045] Salt whey pressed out in Cheddar cheese process was collected from the tower. The salt whey was centrifuged at 7000×g for 15 minutes at 10° C. to remove fat. After adjusted to pH 6.2 with 6 N NaOH, the separated salt whey was concentrated by ultrafiltration and diafiltration using a bench UF unit with a 10K MWCO spiral-wound membrane cartridge. The final concentrate was freeze-dried into a protein powder (salt whey product A; Table 2).

example 2

[0046] The salt whey streams naturally drained from curd and pressed out in later cheese processing were pooled together and separated by a pilot plant separator (Westfalia SA-7). The separated salt whey was concentrated by ultrafiltration and diafiltration using a pilot plant UF unit with two 10K MWCO spiral-wound membranes. The final concentrate was spray-dried into a protein powder (salt whey product B; Table 2).

example 3

[0047] The salt whey pressed out in cheddar cheese process was collected from the tower. It was separated by a pilot plant separator (Westfalia SA-7). The separated salt whey was concentrated by ultrafiltration and diafiltration using a pilot plant UF unit with two 10K MWCO spiral-wound membranes. The final concentrate was spray-dried into a protein powder (salt whey product C; Table 2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com