Milk product, preparation method thereof, dairy product and preparation method thereof

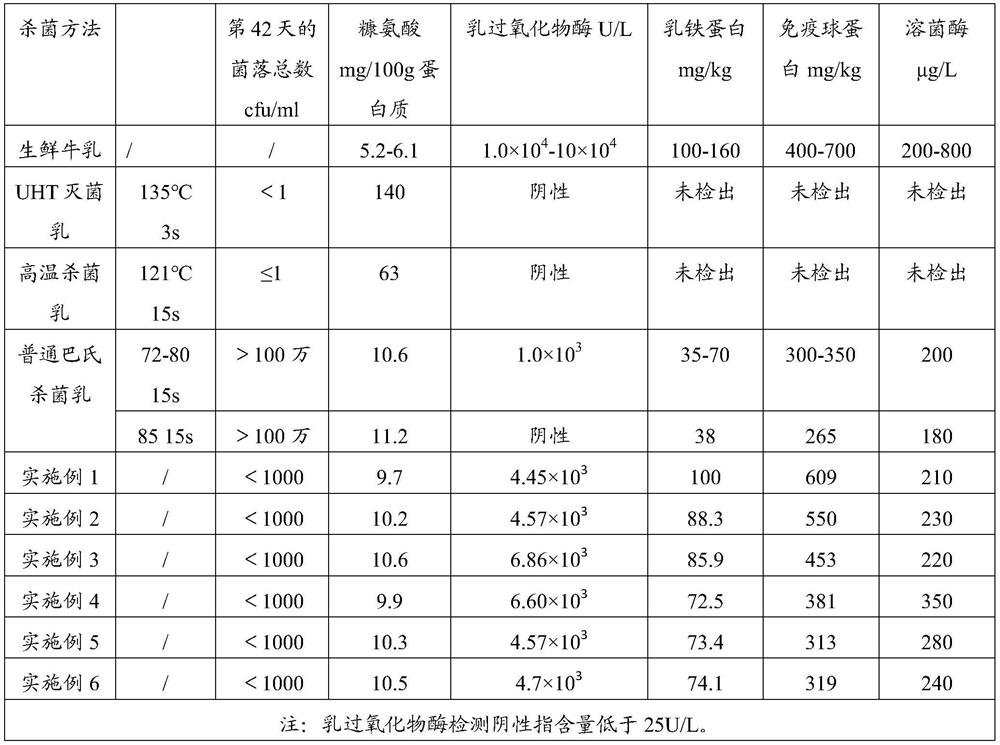

A technology for dairy products and products, applied in the field of dairy products, can solve the problems of long heat treatment time, short shelf life, serious heat load of milk, etc., achieve high biological safety and nutritional activity, reduce the total number of colonies, and improve the effects of biological safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] According to another aspect of the present invention, a method for preparing a milk product is provided. The method includes:

[0040] (1) Clean milk treatment

[0041] In this step, the raw milk is subjected to cold cleaning treatment in order to remove impurities in the raw milk.

[0042] According to an embodiment of the present invention, the temperature of cold-cleaned milk is 2-10°C, including passing raw milk through 80-600 mesh (such as 80 mesh, 100 mesh, 150 mesh, 200 mesh, 250 mesh, 300 mesh, 350 mesh, 400-mesh, 450-mesh, 500-mesh, 550-mesh, 600-mesh) sieve to remove impurities mixed in the raw milk, and then the Centrifuge to remove impurities such as non-milk cells in raw milk.

[0043] It should be noted that the term "raw milk" used in the present invention refers to fresh milk collected from the udder of a dairy cow without further processing.

[0044] (2) RO membrane concentration

[0045] In this step, RO membrane treatment is performed in order to...

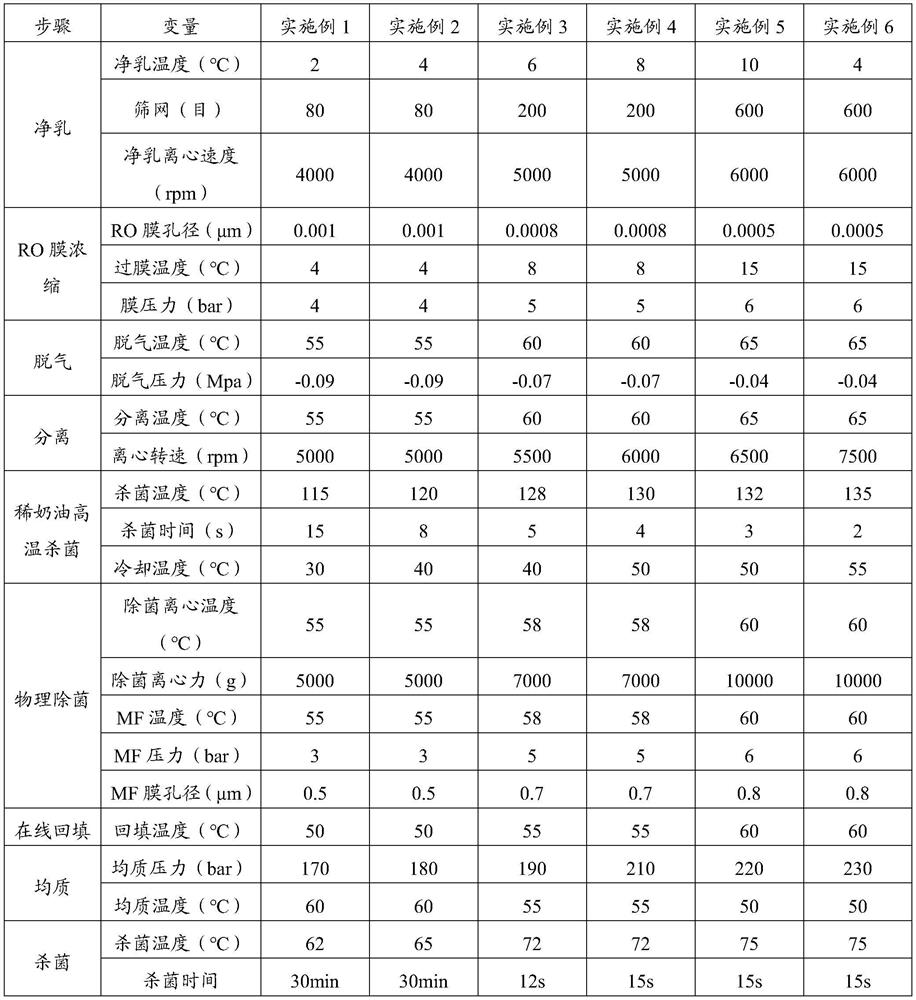

Embodiment

[0073] In this example, a milk product was prepared as follows:

[0074] (1) Selection of raw milk: select healthy dairy cows in large-scale pasture breeding bases, and use fresh milk squeezed from the udders of healthy cows using mechanized milking equipment.

[0075] (2) Acceptance: Inspect the protein, fat, non-fat milk solids, acidity, pH value and the total number of bacteria contained in raw milk. The acceptance standard meets the national standard of GB19301 "Raw Milk". Qualified raw milk is cold-chained at 2-6°C store.

[0076] (3) Milk cleaning: The raw milk is subjected to cold cleaning treatment, filtered with a sieve of 80-600 mesh, and impurities in the milk are removed, and the raw milk is passed through a centrifugal milk cleaning machine (Tetra Pak, model: OCM-15 ) to clean the milk by centrifugation, the temperature is controlled at 2-10° C., and the centrifugation is performed at 4000-6000 rpm to remove impurities in the milk.

[0077] (4) RO membrane conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com