Elongated coil assembly for electromagnetic borehole surveying

a coil assembly and electromagnetic borehole technology, applied in the direction of surveying, directional drilling, borehole/well accessories, etc., can solve the problems of ineffective technique use, limited range of guidance fields produced by such grids, and ordinary techniques for guiding the drilling of boreholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

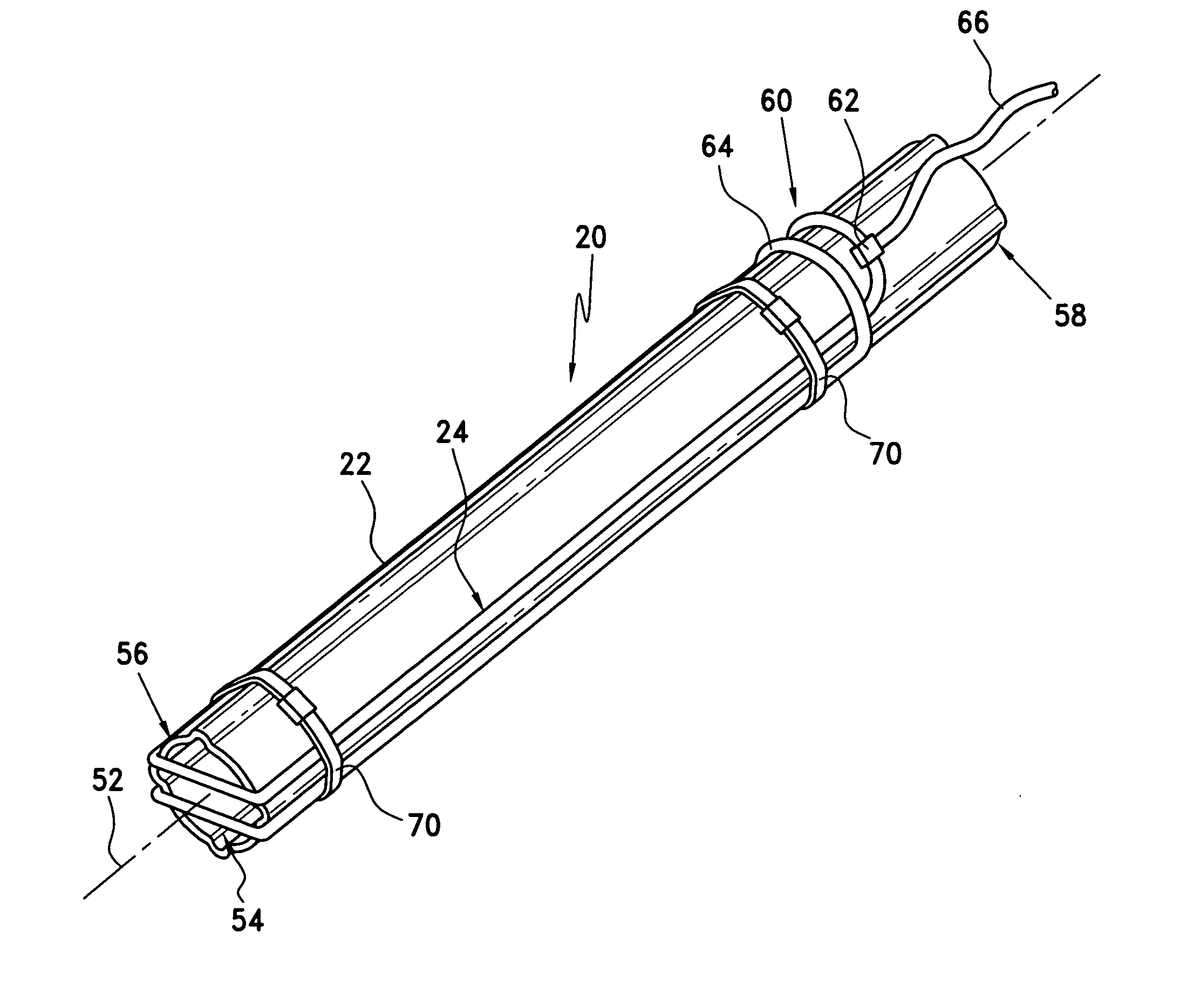

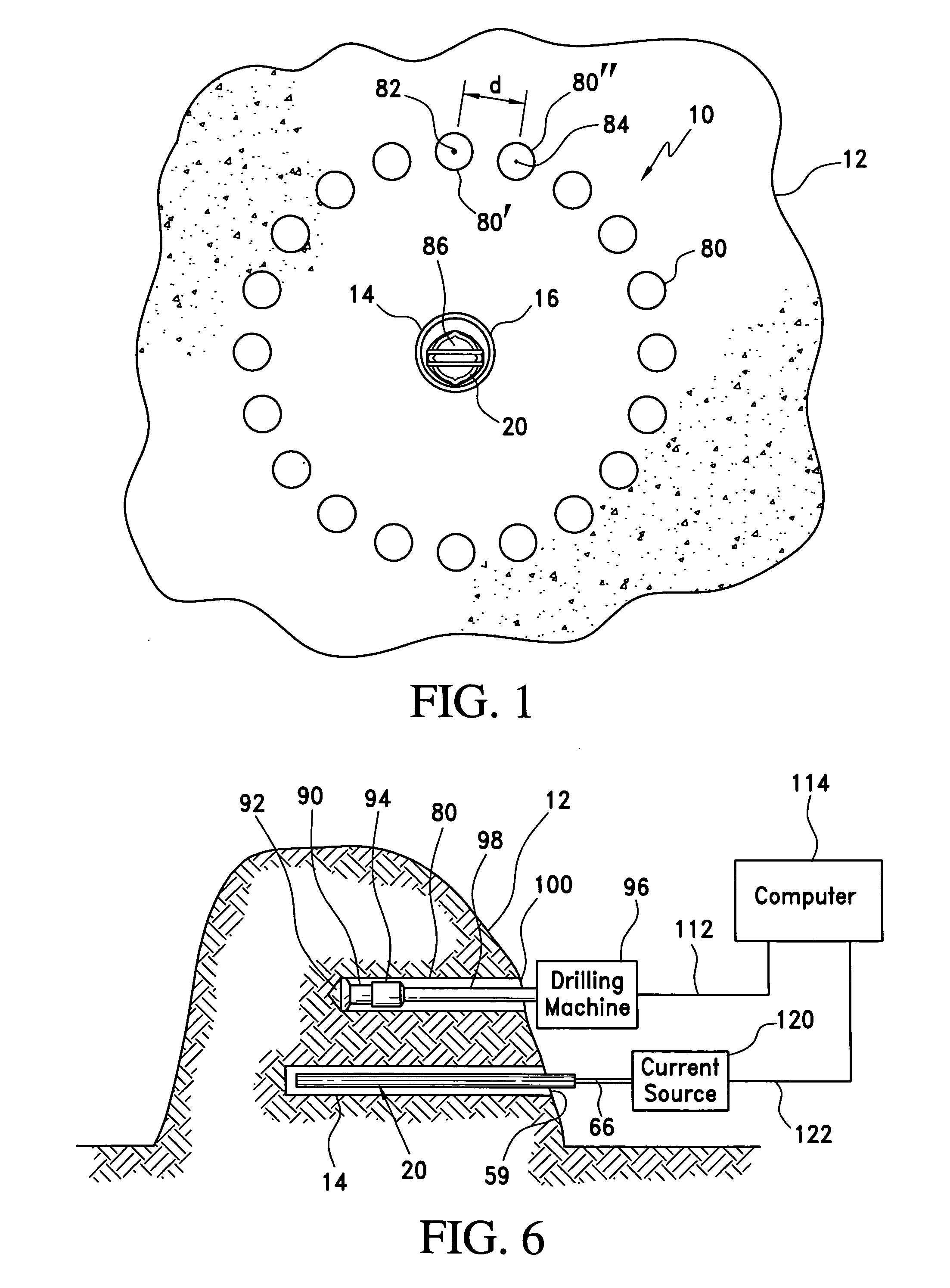

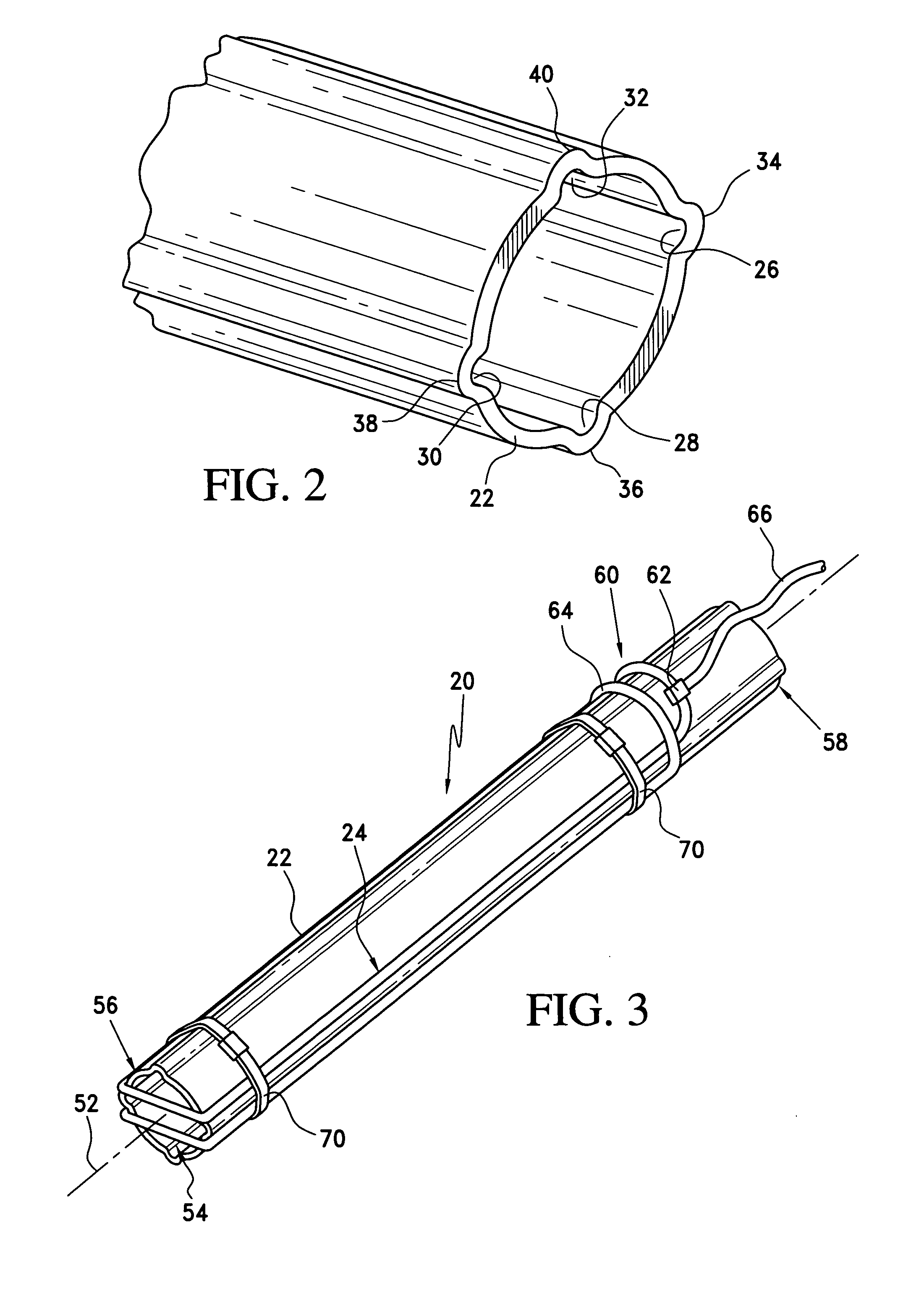

[0024] Turning now to a more detailed description of a preferred embodiment of the present invention, there is illustrated in FIG. 1 a drilling site 10 located in a ground feature 12, such as a hillside, a mountain, or other entryway for one or more generally horizontal boreholes. In the embodiment illustrated in this figure, a plurality of parallel, spaced boreholes defining the circumference of a tunnel to be excavated are illustrated, although it will be understood that the techniques described herein may be used for guiding the drilling of any number of boreholes. In this embodiment, a reference, or guide borehole 14 is first drilled into the earth using known drilling, borehole guidance and logging techniques. The guide borehole may be drilled in a straight line into the side of a mountain, as illustrated in FIG. 6, for example, or may be curved, as when drilling under an obstacle such as a river, lake, or the like, in known manner. The guide borehole preferably is cased with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com