Reservoir housing having a conductive region integrally formed therein

a conductive region and reserve housing technology, applied in the direction of conductive pattern formation, manufacturing tools, therapy, etc., can solve the problems of limiting the patient's movement and mobility, affecting the patient's comfort,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

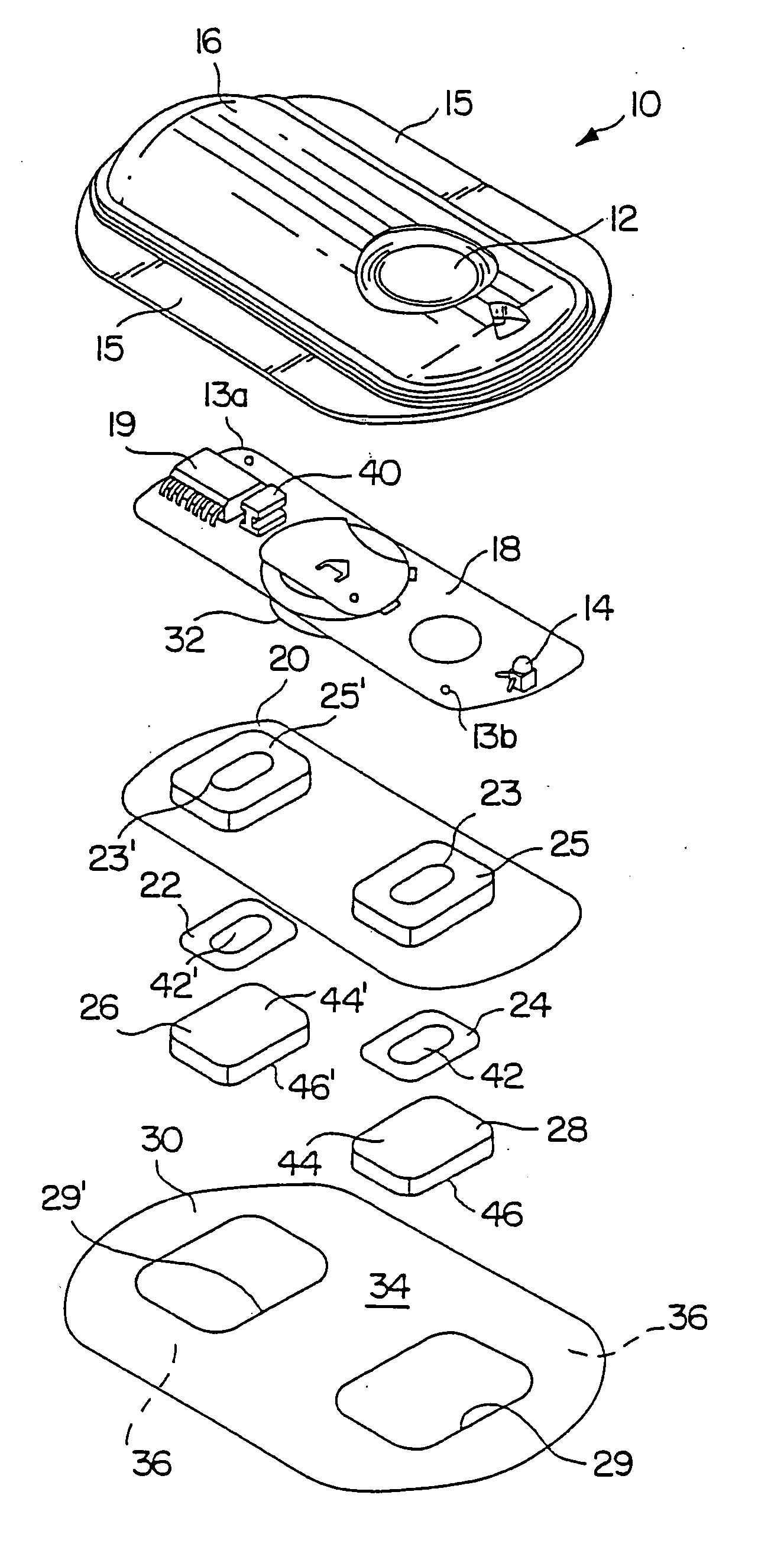

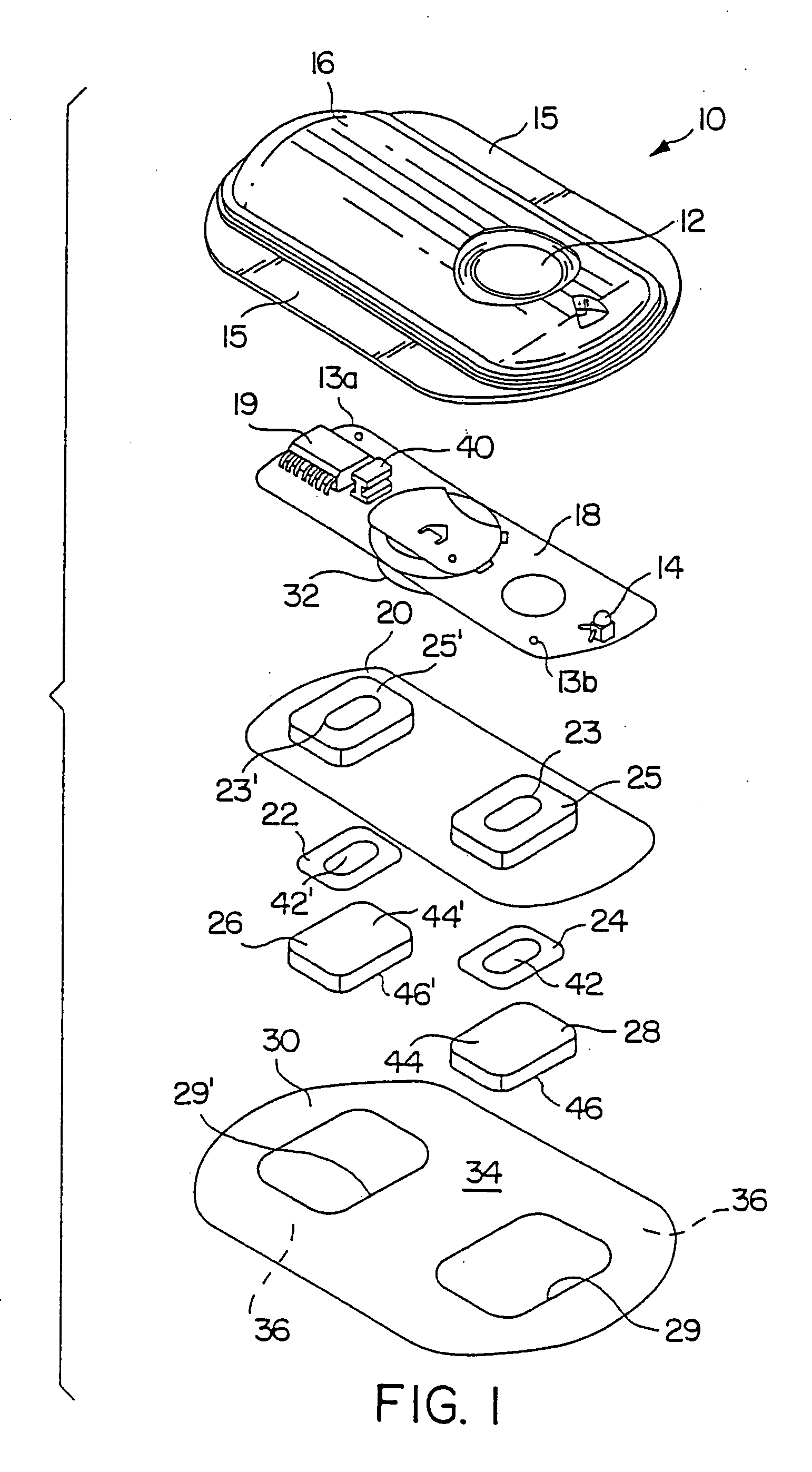

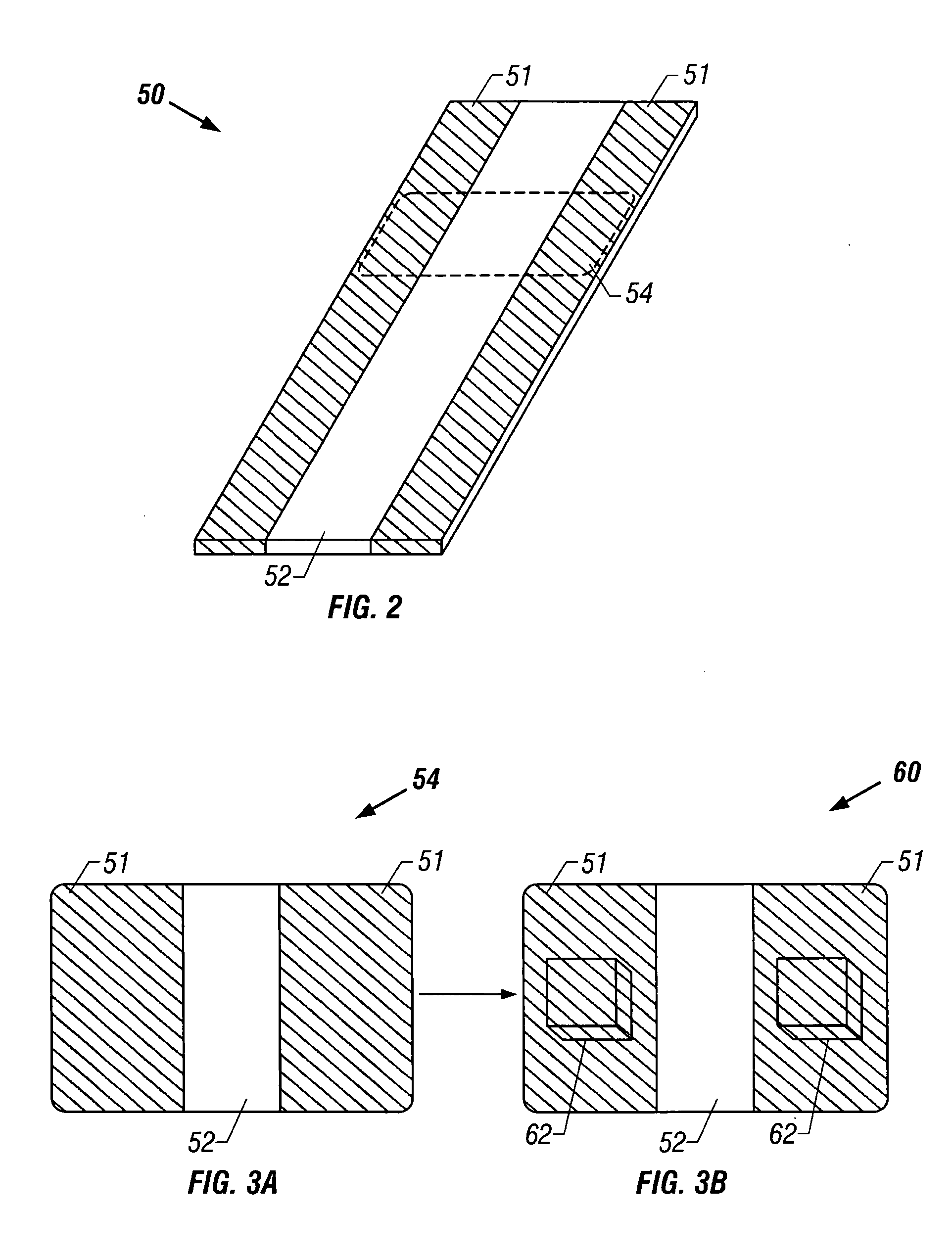

[0019] The present invention provides an electrotransport reservoir housing formed from a single piece of material having at least two conductive sections and at least one non-conductive section. This material can be formed by co-extruding a non-conductive strip located between two conductive strips. A reservoir blank, which is a section of the appropriate size, is punched across the extruded material such that a conductive region is located at each end of the piece and the non-conductive section is in the middle of the piece, between the two conducive regions. This reservoir blank is then thermoformed to fabricate an integral reservoir housing having two cavities, one at each end of the piece. Each cavity is formed from one of the two conductive regions and the two cavities are separated and insulated from each other by the section of non-conductive material.

[0020] Once extruded, the three part material is thermoformed into a reservoir housing which functions as an integral sheet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

| non-conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com