Semiconductor device and method for fabricating the same

a technology of semiconductor devices and semiconductors, applied in the direction of semiconductor devices, electrical equipment, transistors, etc., can solve problems such as unfavorable electrical leakage, and achieve the effect of improving the quality of semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

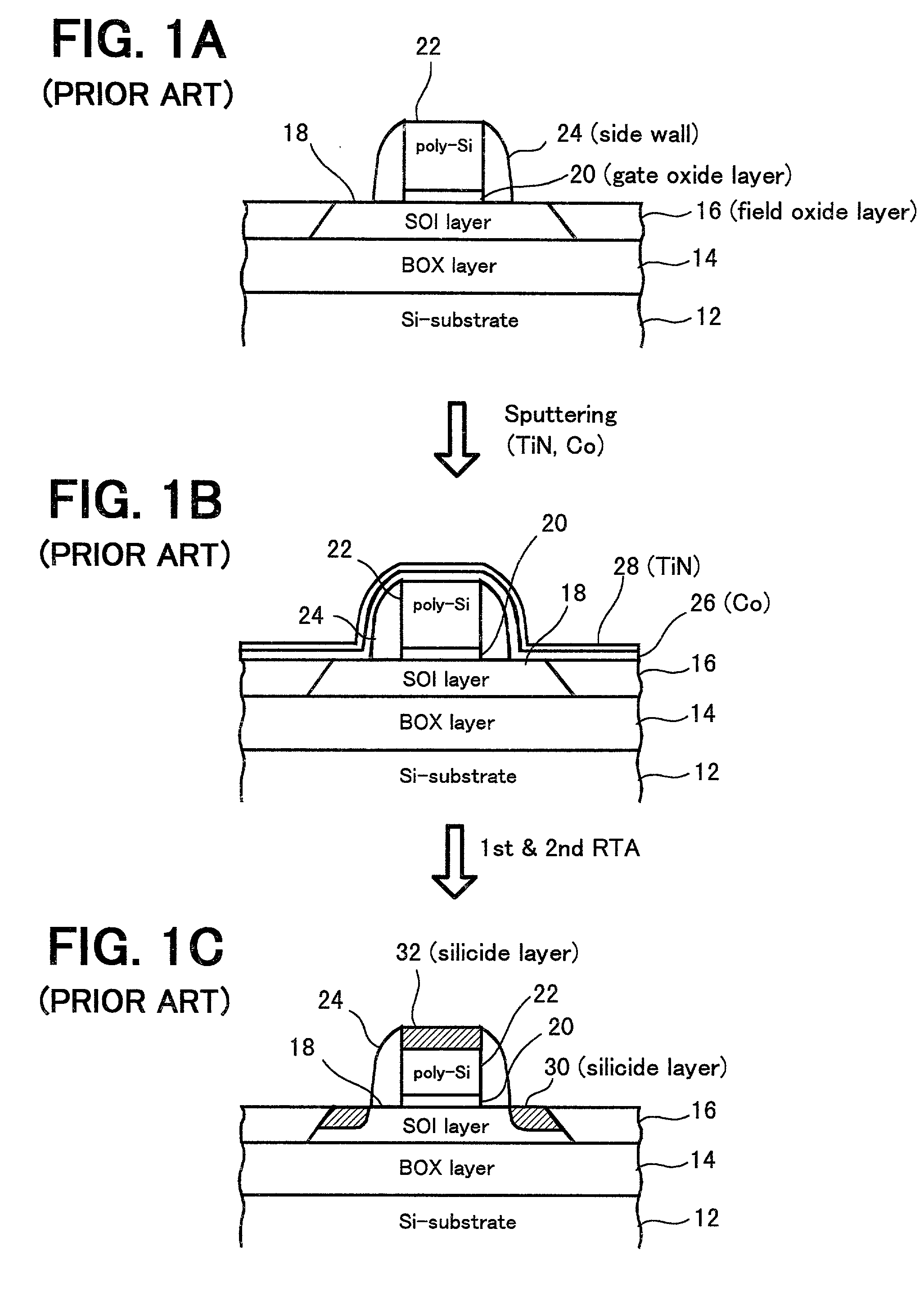

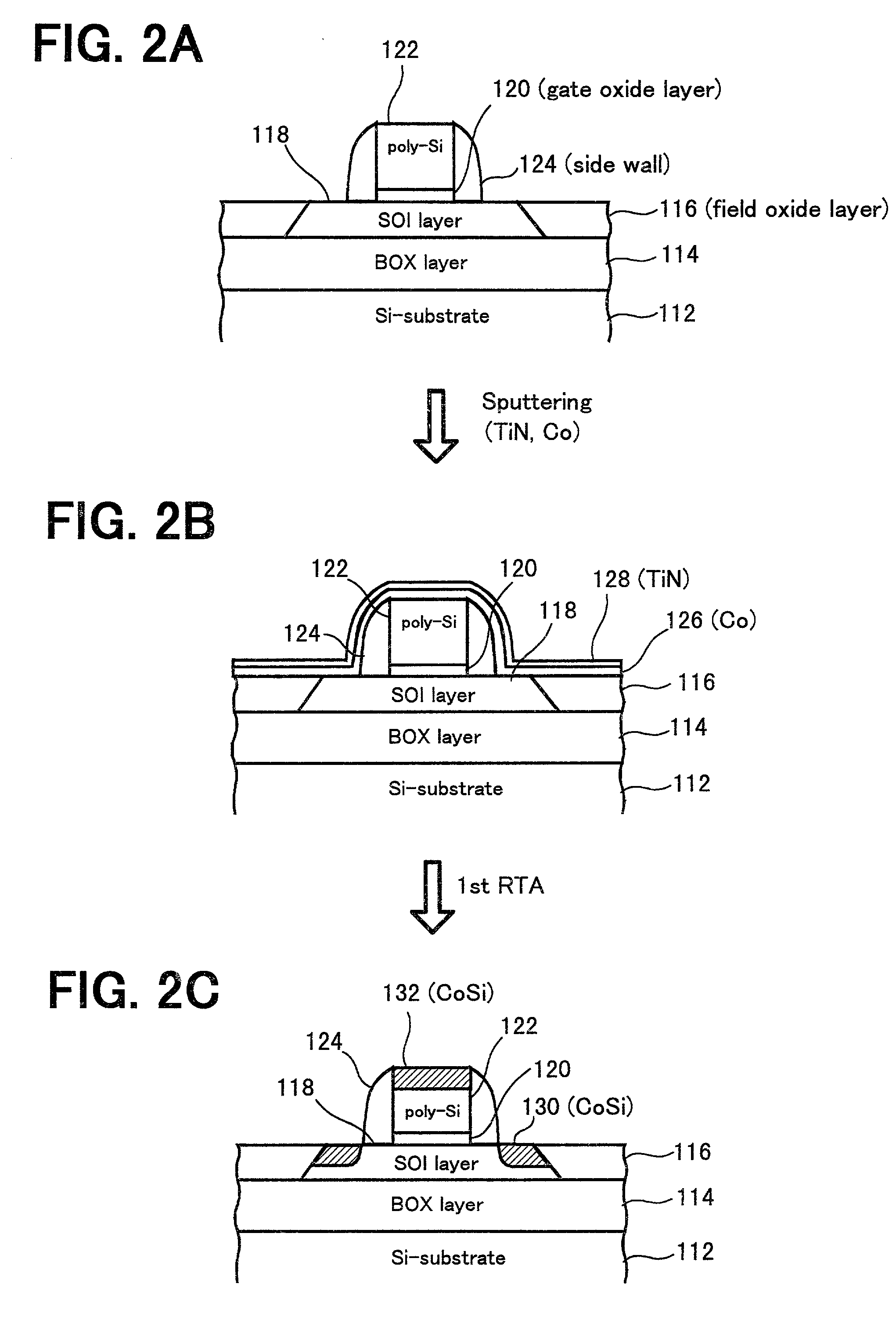

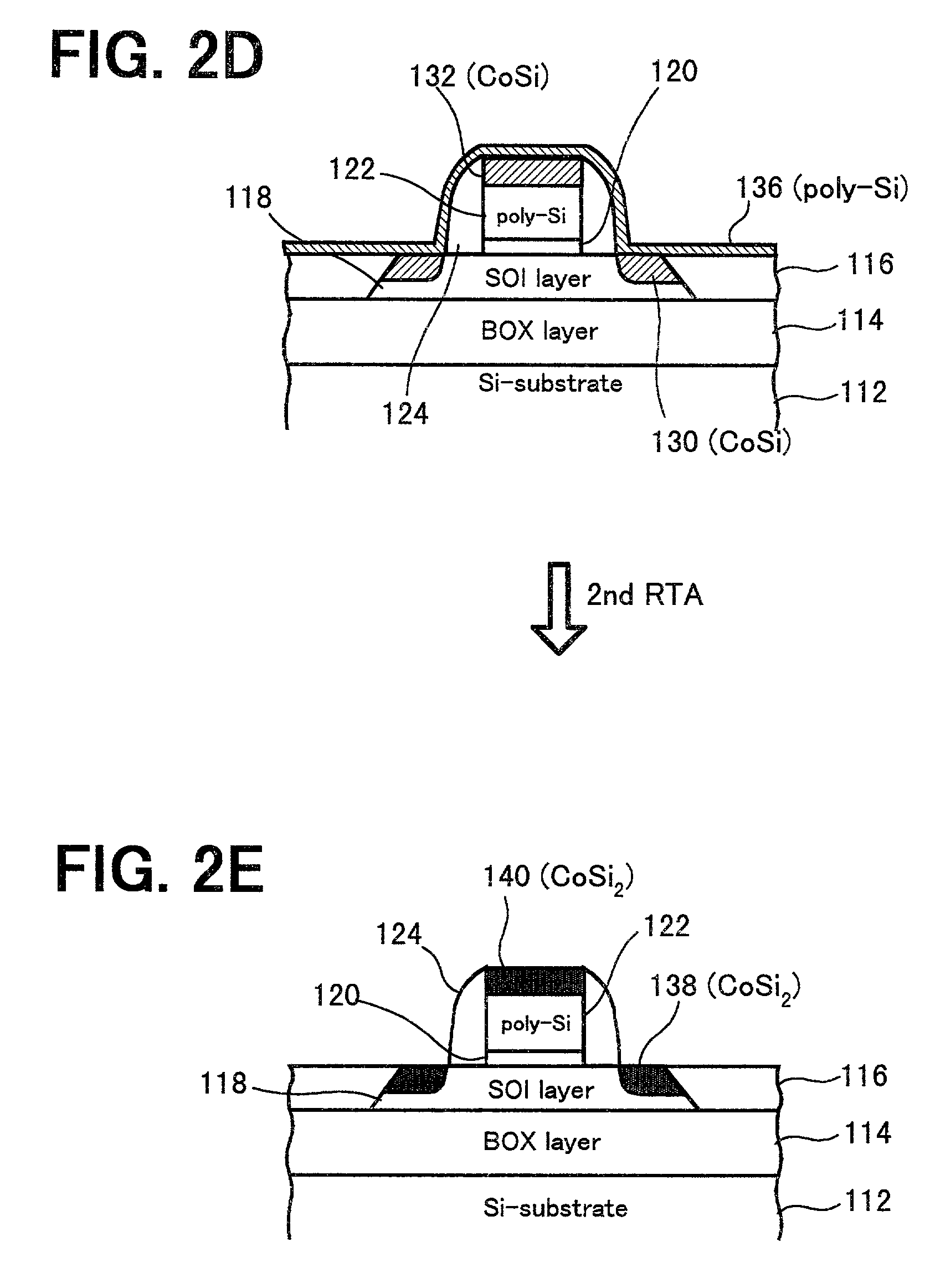

[0021] For better understanding of the present invention, a conventional technology is first described. FIGS. 1A to 1C are cross-sectional views showing fabrication steps of a conventional semiconductor device. FIGS. 1A to 1C show salicide process of a SOI (Silicon on Insulator) type of semiconductor device.

[0022] FIG. 1A shows a condition in which gate-side-wall process is completed. As shown in FIG. 1A, a BOX (Buried Oxide) layer 14 is formed on a silicon substrate 12 to have a thickness of 100 nm to 200 nm. A filed oxide layer 16 and a SOI (Silicon on Insulator) layer 18 are formed on the BOX layer 14. The SOI layer 18 is of FD (Fully Depletion) type and is designed to have a thickness of 50 nm to 100 nm. A gate oxide layer 20 is formed on the SOI layer 18 to have a thickness of 3.5 nm to 7.0 nm. A poly-silicon gate layer 22 is formed on the gate oxide layer 20 to have a thickness of 150 nm to 250 nm. A gate side wall layer 24 is formed on the SOI layer 18 to surround the poly-si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com