Device and system for improved cleaning in a washing machine

a washing machine and cleaning technology, applied in the direction of washing machines, cleaning using liquids, detergent compounding agents, etc., can solve the problems of requiring significant investment by owners, affecting the use of washing machines, and creating a glut of obsolete washing machines with limited us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

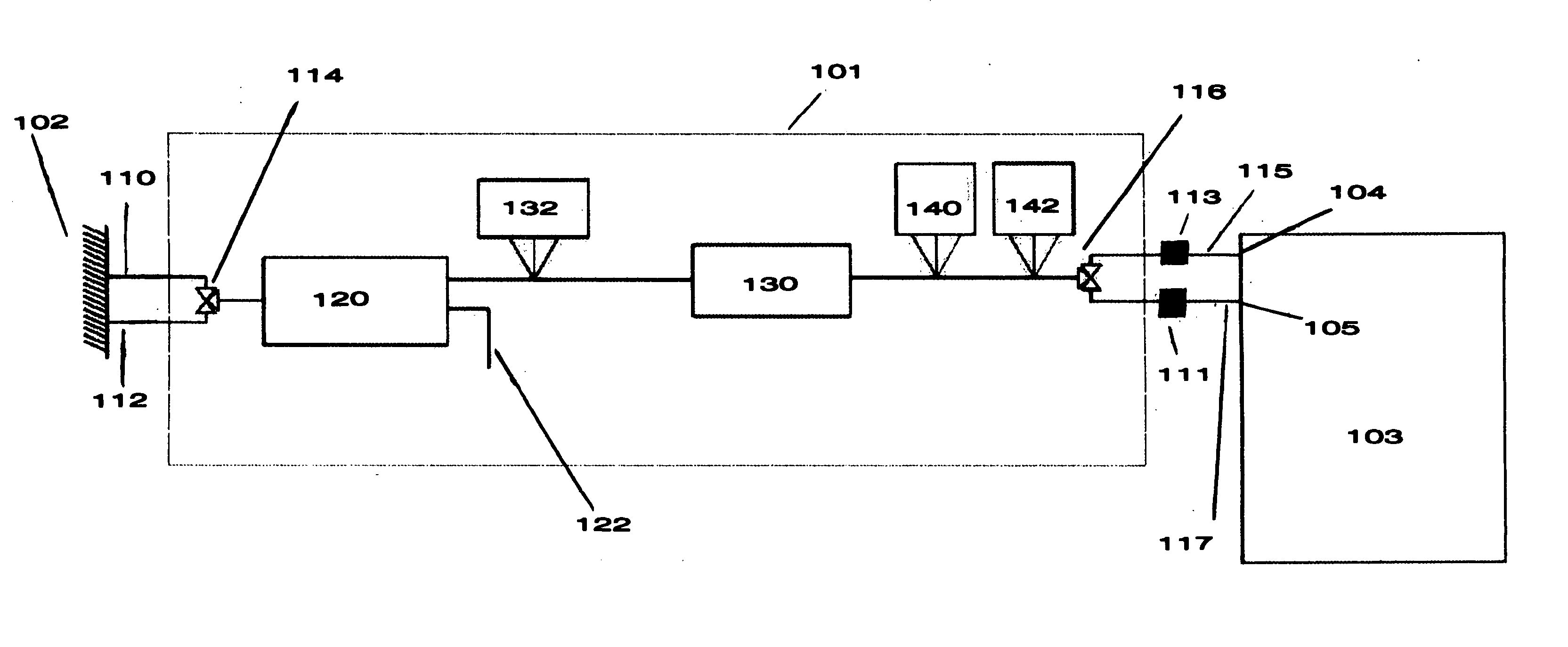

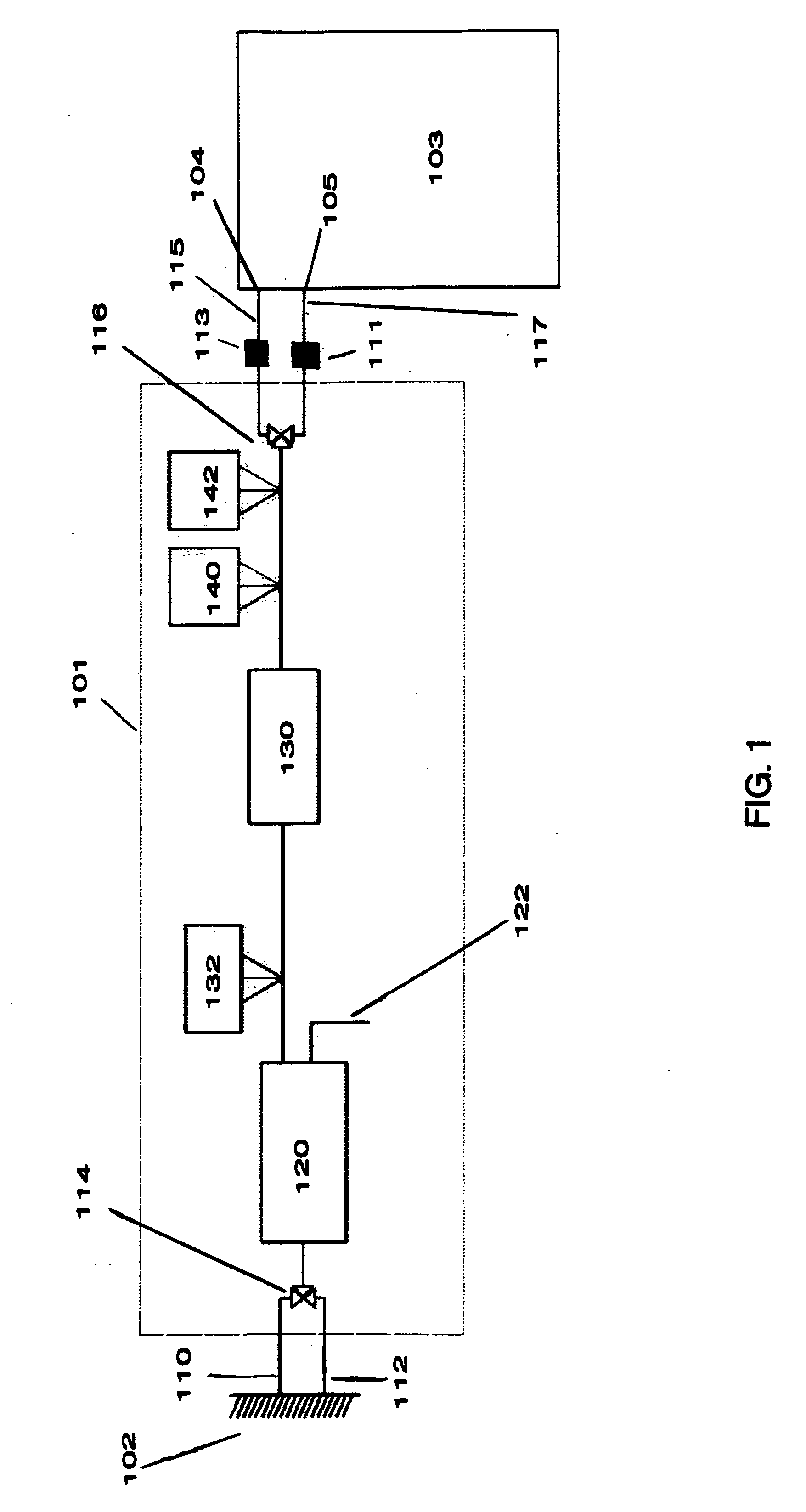

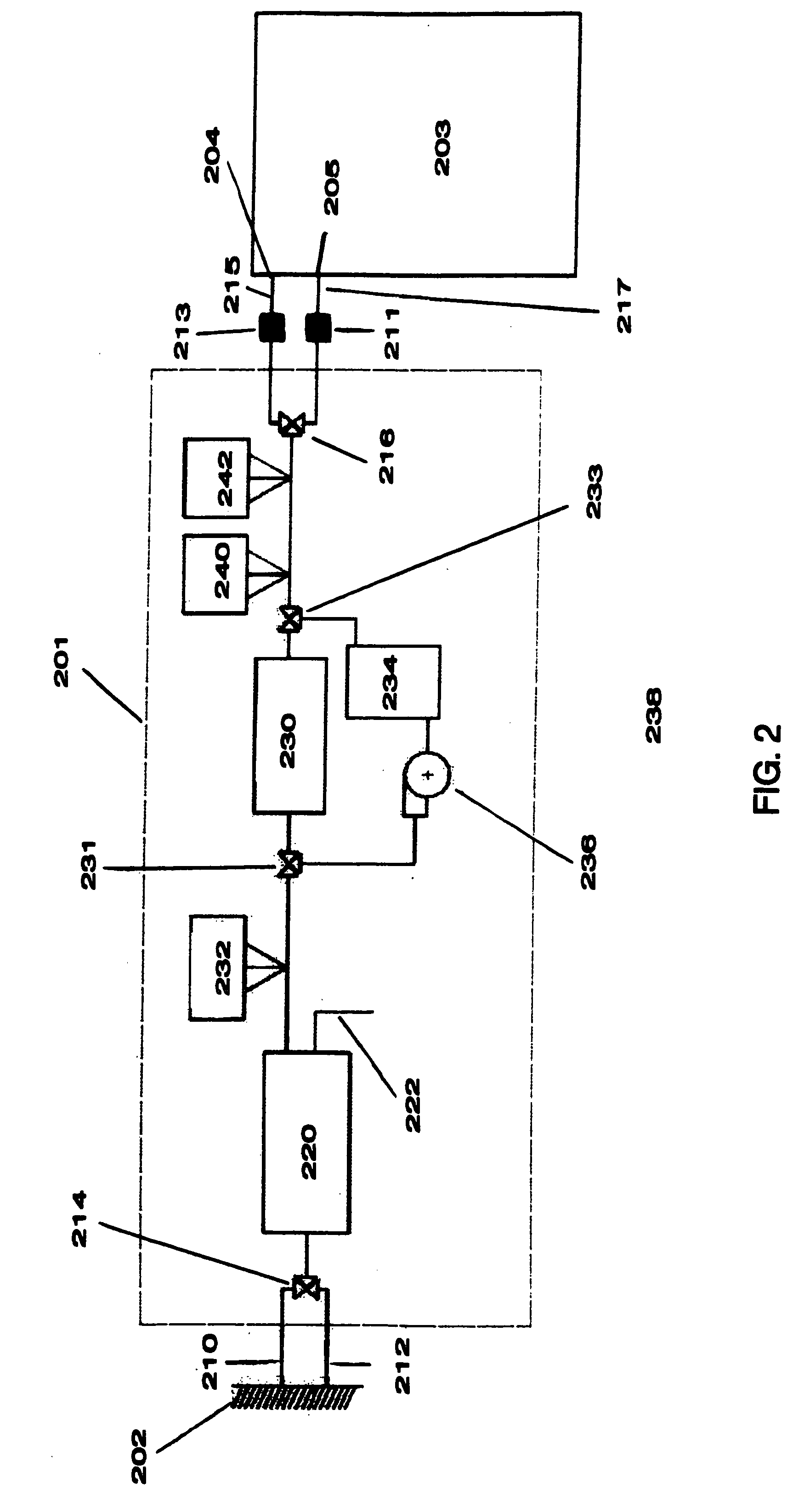

[0083]FIGS. 1-3 are included to provide non-limiting examples of the methods and devices of the present invention.

[0084]FIG. 1 comprises device 101, feed water 102 and wash zone 103. When wash zone 103 requests cold water 112 or hot water 110, the pressure drop is detected by hot water pressure sensor 113 and / or cold water pressure sensor 111. Hot water pressure sensor 113 and / or cold water pressure sensor 111 communicates with feed water valve 114 and / or outlet water valve 116 to open or close. For hot water treatment, feed water valve 114 and outlet water valve 116 are opened such that hot water 110 flows through device 101. For cold water treatment, feed water valve 114 and outlet water valve 116 are opened such that cold water 112 flows through device 101. Combinations of hot water 110 and cold water 110 can be formed by either opening feed water valve 114 and outlet water valve 116 partially so that hot water 110 and cold water 112 mix within device 101 or by alternating feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com