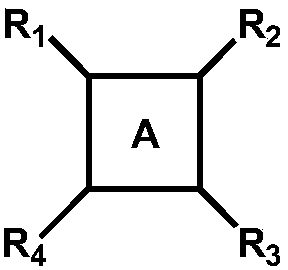

Aliphatic polyamide loose reverse osmosis membrane as well as preparation method and application thereof

An aliphatic polyamide, loose reverse osmosis technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of divalent, poor pollution resistance, low retention rate, etc., to achieve excellent divalent salts Retention rate, effect of excellent contamination resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method for an aliphatic polyamide loose reverse osmosis membrane, comprising the following steps:

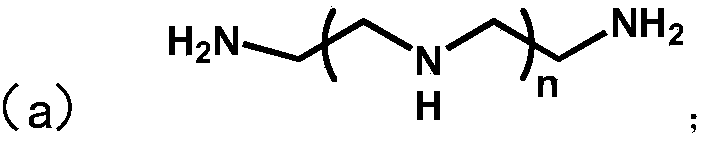

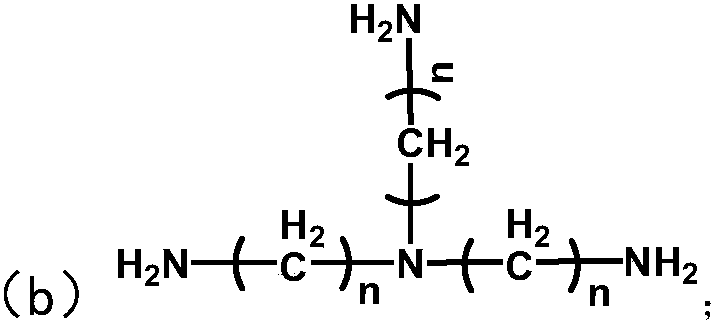

[0041] (1) First soak the polyethersulfone ultrafiltration bottom membrane in the chain aliphatic amine solution, take it out after 120s, and purge the surface of the ultrafiltration membrane with gas to remove the excess chain aliphatic amine solution on the ultrafiltration membrane surface, wherein, The chain aliphatic amine solution is composed of diethylenetriamine and water, the mass fraction of diethylenetriamine is 1wt%, and the massfraction of water is 99wt%;

[0042] (2) Soak the cycloaliphatic acid chloride solution on the polyethersulfone ultrafiltration bottom membrane that contains the chain aliphatic amine solution on the surface prepared in step (1) to carry out interfacial polymerization, take it out after 60s, wherein the cycloaliphatic acid chloride solution is prepared by Composed of 1,3,5-cyclohexanetrichloride and an oil phase solvent, t...

Embodiment 2

[0049] A preparation method for an aliphatic polyamide loose reverse osmosis membrane, comprising the following steps:

[0050] (1) Coating chain-like aliphatic amine solution on the polyethersulfone ultrafiltration bottom membrane, after 120s, purging the surface of the ultrafiltration membrane with gas to remove excess chain-like aliphatic amine solution on the surface of the polyethersulfone ultrafiltration membrane, Wherein, the chain aliphatic amine solution is composed of tris(2-aminoethyl)amine and water, the mass fraction of tris(2-aminoethyl)amine is 1.5wt%, and the mass fraction of water is 98.5wt%;

[0051] (2) Soak the alicyclic acid chloride solution on the polyethersulfone ultrafiltration bottom membrane containing the chain aliphatic amine solution prepared in step (1) to carry out interfacial polymerization, and take it out after 60s, wherein the alicyclic acid chloride The solution is composed of 1,3,5-cyclohexanetrichloride and an oil phase solvent, the oil p...

Embodiment 3

[0058] A preparation method for an aliphatic polyamide loose reverse osmosis membrane, comprising the following steps:

[0059] (1) First soak the polyethersulfone ultrafiltration bottom membrane in the chain aliphatic amine solution, take it out after 4 minutes, and purge the surface of the polyethersulfone ultrafiltration membrane to remove the excess chain aliphatic amine solution on the surface of the ultrafiltration membrane , wherein the chain aliphatic amine solution is composed of tris(2-aminoethyl)amine, acetone and water, the mass fraction of tris(2-aminoethyl)amine is 1wt%, the massfraction of water is 98wt%, acetone The mass fraction of is 1wt%;

[0060] (2) Soak the alicyclic acid chloride solution on the polyethersulfone ultrafiltration bottom membrane containing chain aliphatic amine solution on the surface of the polyethersulfone ultrafiltration membrane prepared in step (1) to carry out interfacial polymerization, take it out after 90s, Wherein, the alicyclic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com