Nanofiltration membrane with brush-shaped zwitterionic polymer modified layer and preparation method thereof

A technology of zwitterions and polymers, which is applied in the field of nanofiltration membranes, can solve the problems of decreased ion retention performance and functional layer damage of nanofiltration membranes, and achieves good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

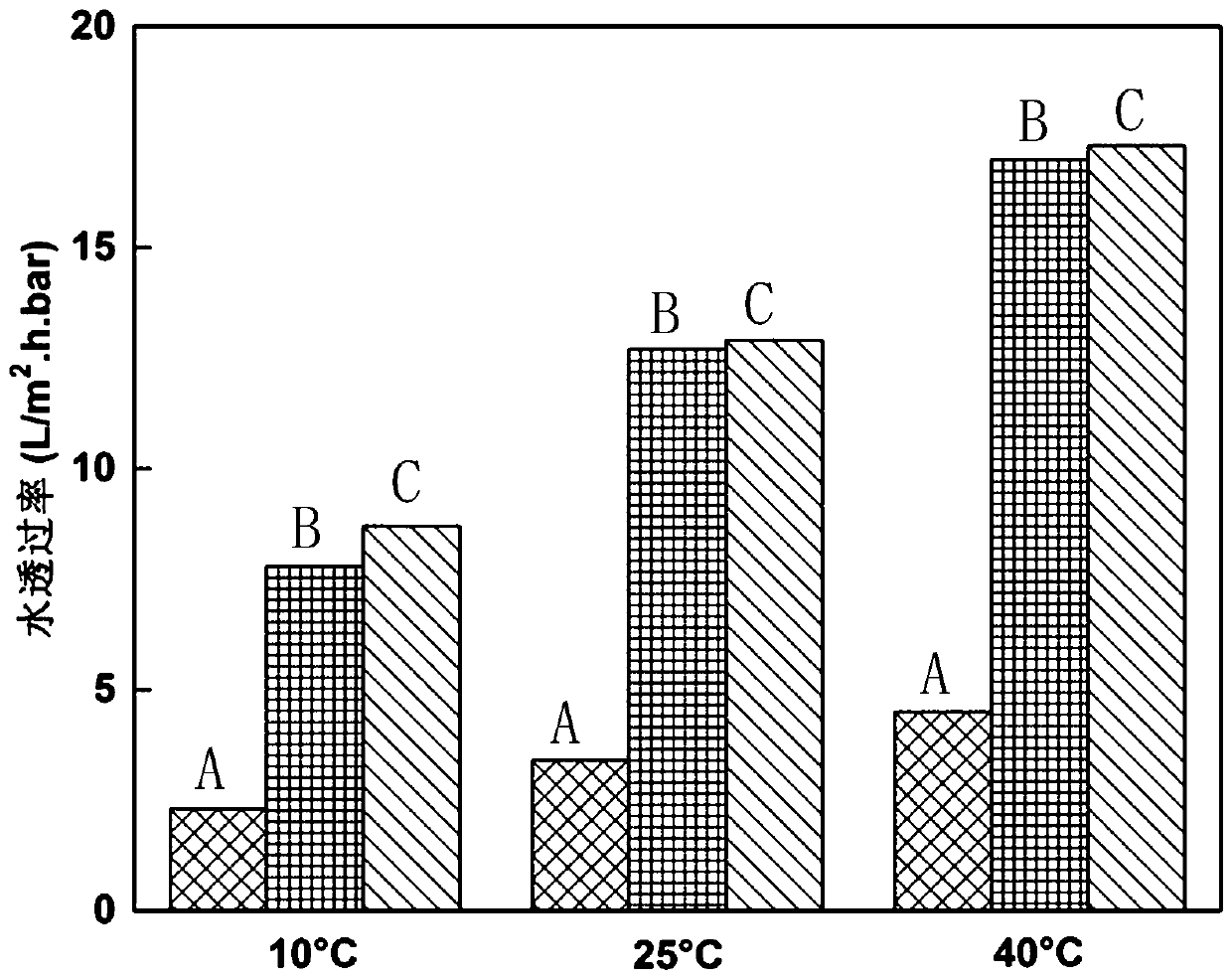

[0022] The preparation environment of all initial nanofiltration membranes in the present invention is: temperature is 25°C, humidity is 40%, and normal pressure.

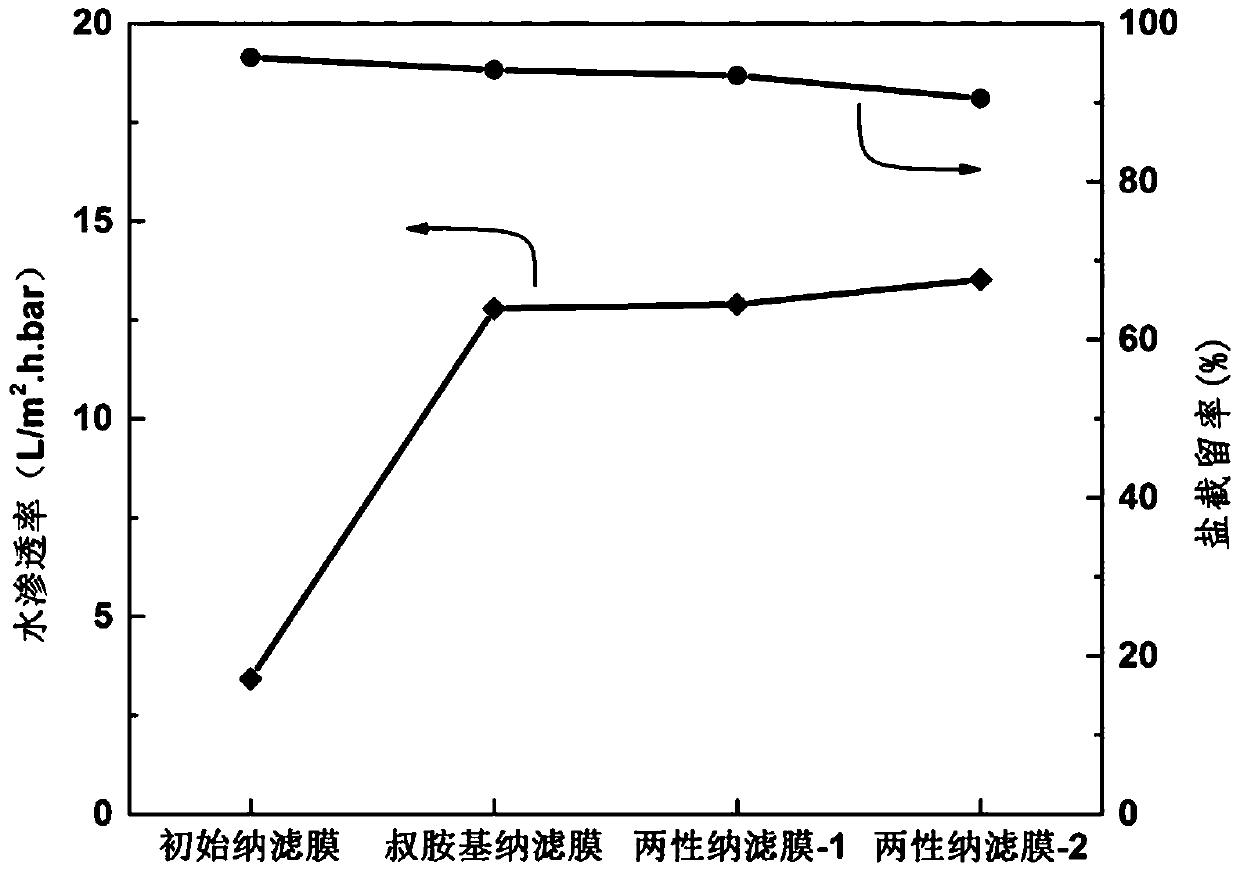

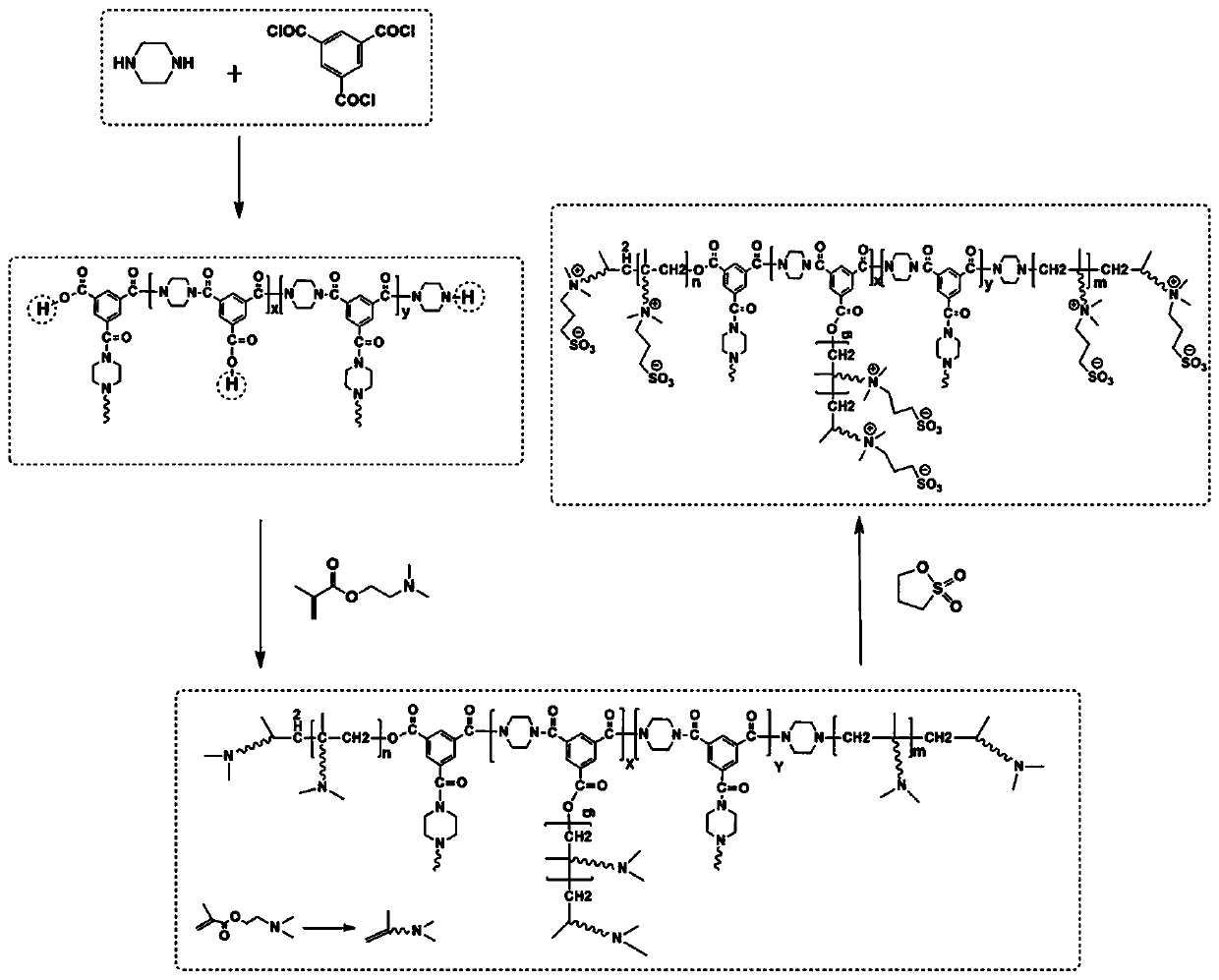

[0023] A high-flux, high-retention brush-like zwitterionic nanofiltration membrane is characterized in that it is a high-flux, high-retention brush composed of a polysulfone ultrafiltration membrane as a support layer and an amphoteric polyimide layer as a functional layer. zwitterionic nanofiltration membrane. The steps of its preparation method are as follows:

[0024] (1) Soaking the polysulfone ultrafiltration membrane supporting membrane and the water phase monomer to form a water phase liquid layer; wherein the water phase monomer is piperazine.

[0025] (2) The described aqueous phase liquid layer is contacted with the organic phase solution containing active monomer, forms polyimide layer on the surface of polysulfone ultrafiltration support layer by interfacial polymerization, obtains initial nanofiltrati...

Embodiment 1

[0029] Specific steps are as follows:

[0030] (1) Immerse 0.2wt% piperazine aqueous solution with pH=10 on the polysulfone ultrafiltration membrane support layer, after immersion for 4min, pour off the aqueous solution, and dry the membrane to form an aqueous phase liquid layer on its surface;

[0031] (2) The aqueous phase liquid layer and 0.1wt% trimesoyl chloride-n-hexane solution are polymerized through the interface of 1min, and a polyimide layer is formed on the surface of the polysulfone ultrafiltration membrane support layer to obtain the initial nanofiltration membrane .

Embodiment 2

[0033] Specific steps are as follows:

[0034] (1) Immerse 0.2wt% piperazine aqueous solution with pH=10 on the polysulfone ultrafiltration membrane support layer, after immersion for 4min, pour off the aqueous solution, and dry the membrane to form an aqueous phase liquid layer on its surface;

[0035] (2) The aqueous phase liquid layer and 0.1wt% trimesoyl chloride-n-hexane solution are polymerized through the interface of 1min, and a polyimide layer is formed on the surface of the polysulfone ultrafiltration membrane support layer to obtain the initial nanofiltration membrane ;

[0036] (3) With the described initial nanofiltration membrane, dimethylaminoethyl methacrylate and a concentration of 4 × 10 -4 g / mL of azobisisobutyronitrile ethanol solution at 40°C for 4 hours to obtain a nanofiltration membrane (modified nanofiltration membrane: NF-PDMA) containing tertiary amine groups, and deionized water After cleaning, the ethanol solution of 1,3-propane sultone with a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com