Device and method for softening hard water by using carbon dioxide in flue gas

A carbon dioxide and hard water technology, applied in the field of water treatment, can solve the problems of secondary pollution, large amount of dosing, easy saturation, etc., and achieve the effect of reducing pollution and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

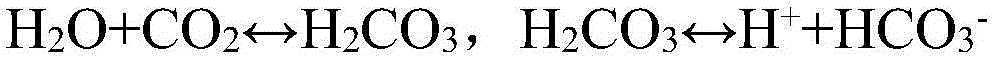

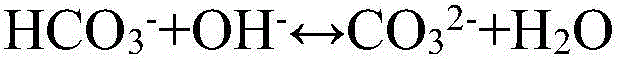

Method used

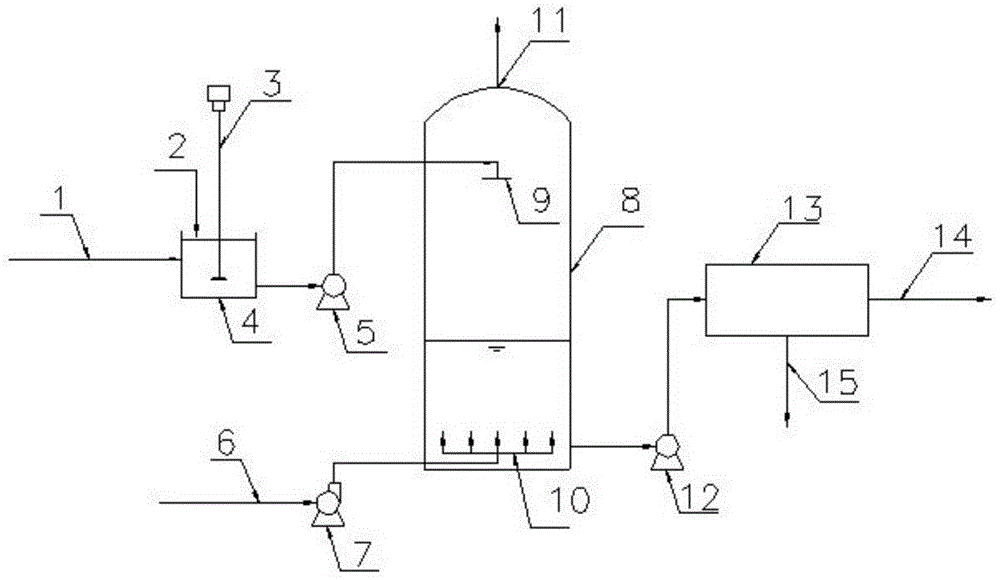

Image

Examples

Embodiment 1

[0037] Embodiment 1 The present invention utilizes carbon dioxide in flue gas to soften hard water to carry out the effect of water treatment

[0038] In order to verify the effect of the present invention, a certain high-hardness groundwater is used as the experimental object. The groundwater (take two parts of 500ml) before treatment, the total dissolved solids TDS is 5800mg / l, the total hardness (as CaCO 3 Calculated) is about 1200mg / L, mainly the permanent hardness of calcium and magnesium ions, the pH value is 6.8, first adjust the pH value to 10.5, and then pass the boiler flue gas into the water for about 1 minute, it can be observed that the water sample becomes turbid obviously, A milky white precipitate was formed, and then the water sample was filtered with filter paper, and the total hardness of the filtrate was measured to be 28mg / l, and the TDS was 5880mg / l. As a comparison, take the same water sample and use the traditional softener NaCO 3 To conduct experimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com