Washing machine with detection device

a detection device and washing machine technology, applied in other washing machines, cleaning using liquids, textiles and paper, etc., can solve the problems of deterioration in price competitiveness, increase in the overall parts of the washing machine, increase in the number of manufacturing steps, etc., to achieve easy manufacturing, reduce manufacturing costs, and simplify the effect of structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Reference will now be made in detail to illustrative, non-limiting embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to the like elements throughout. The exemplary embodiments described below explain the present invention by referring to the figures.

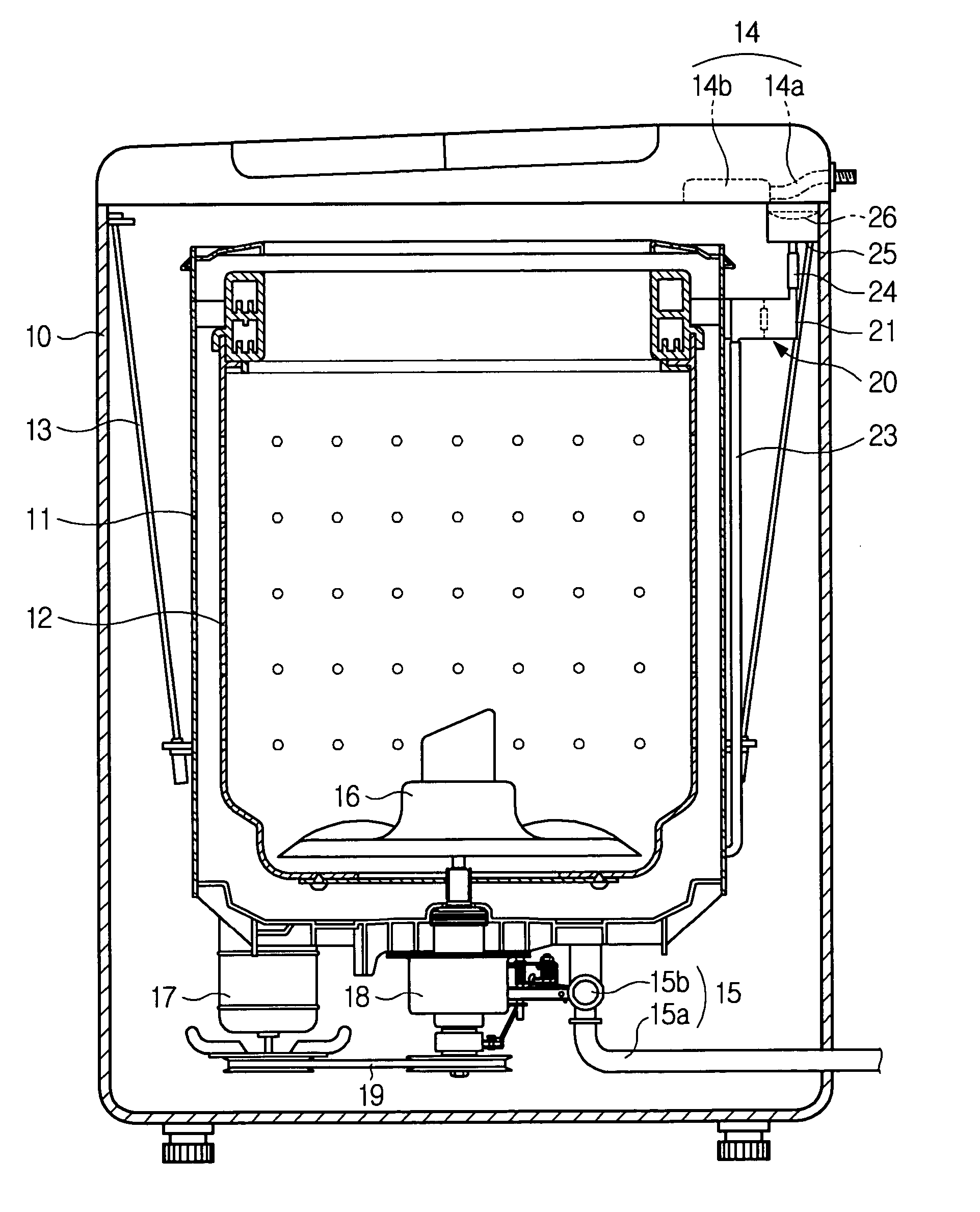

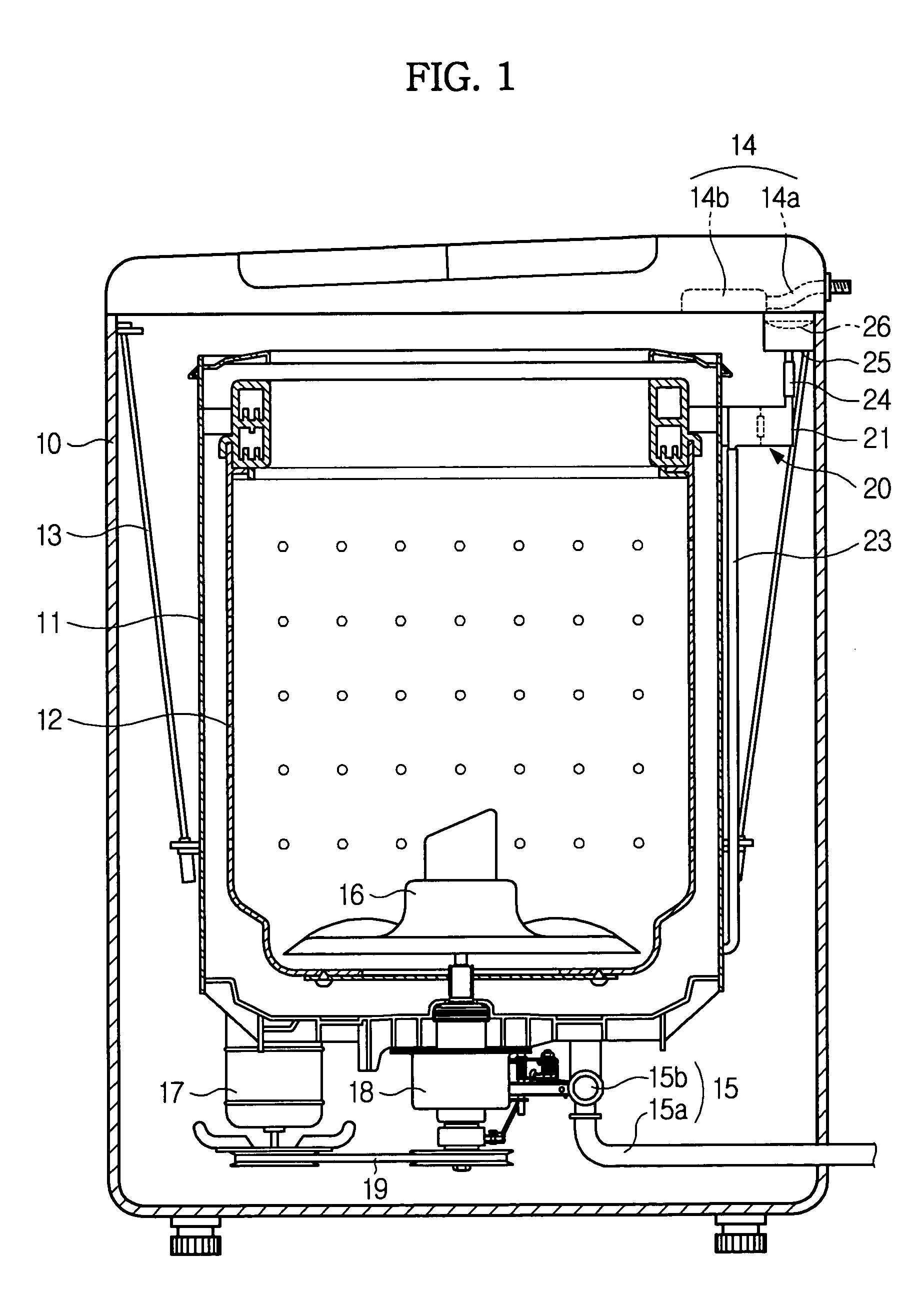

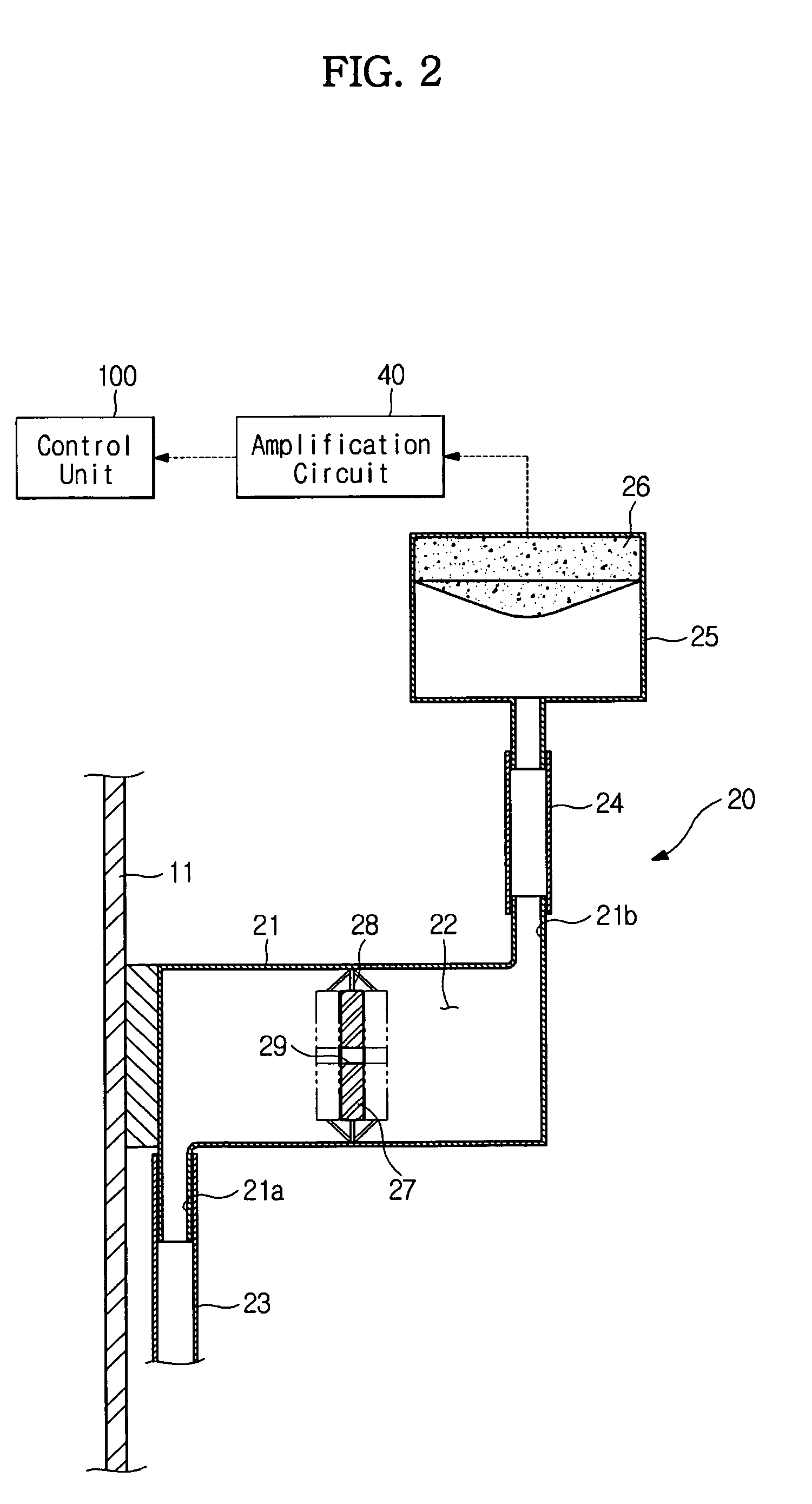

[0028] Referring to FIG. 1, the washing machine of a first exemplary embodiment comprises a water tub 11 installed in a body case 10 and adapted to contain wash water, and a washing tub 12 rotatably installed in the water tub 11. The water tub 11 is supported at a lower exterior side thereof by means of suspension devices 13. The washing machine further comprises a water supply device 14 having a water supply pipe 14a and a water supply valve 14b mounted at an upper portion of the water tub 11 for supplying the wash water into the water tub 11, and a drainage device 15 having a drainage pipe 15a and a drainage valve 15b mounted at a lower po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com