Cushion plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

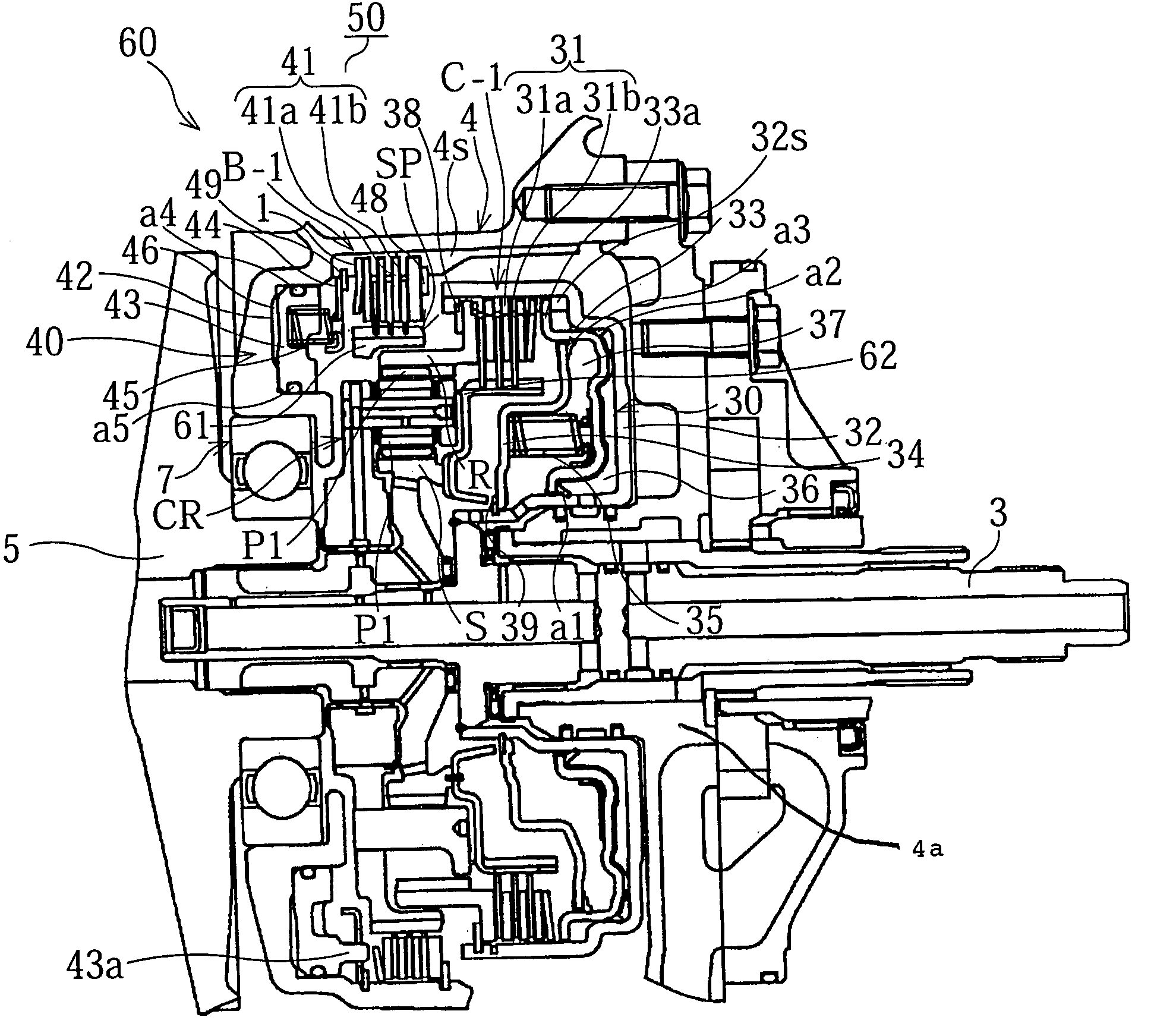

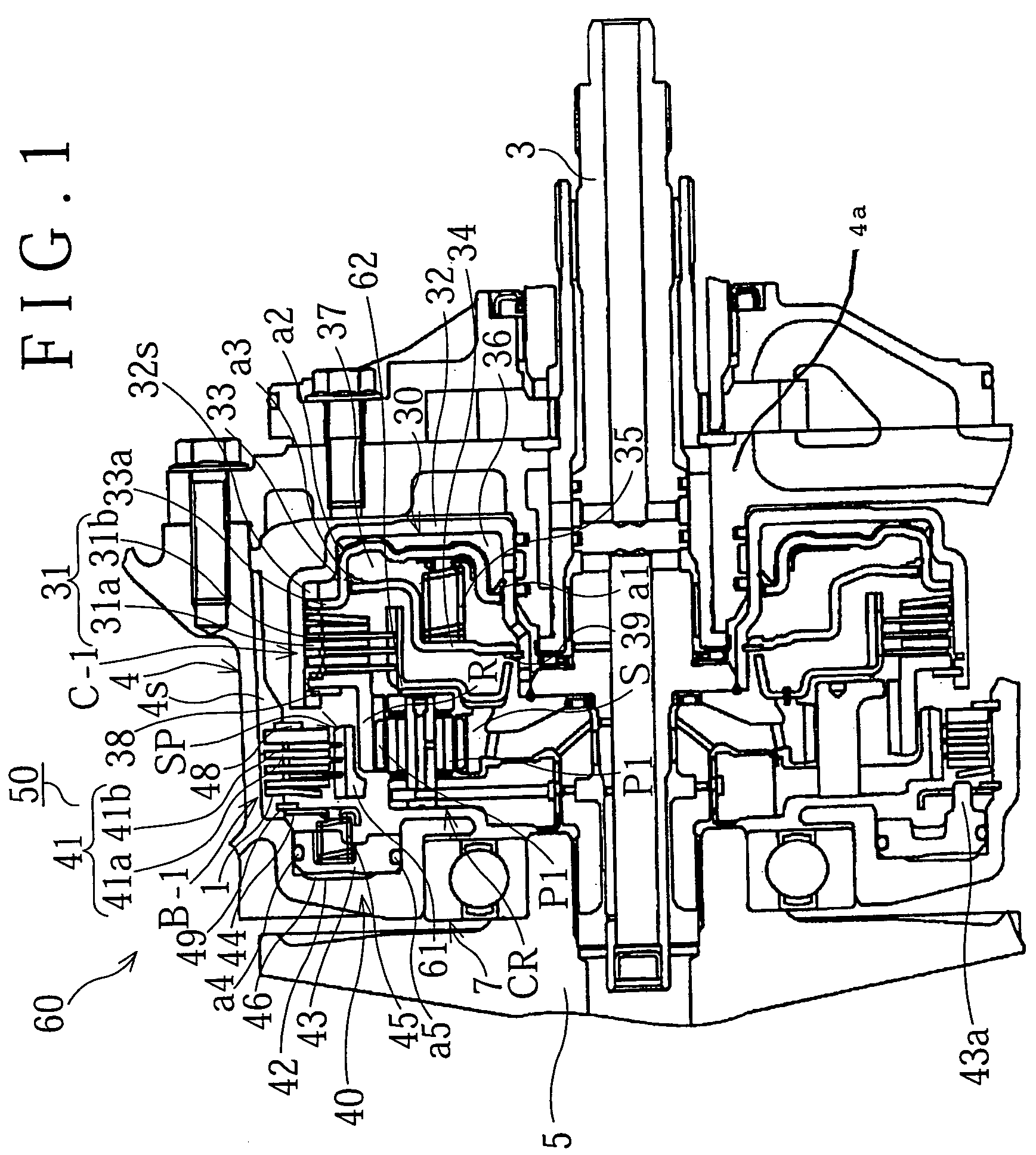

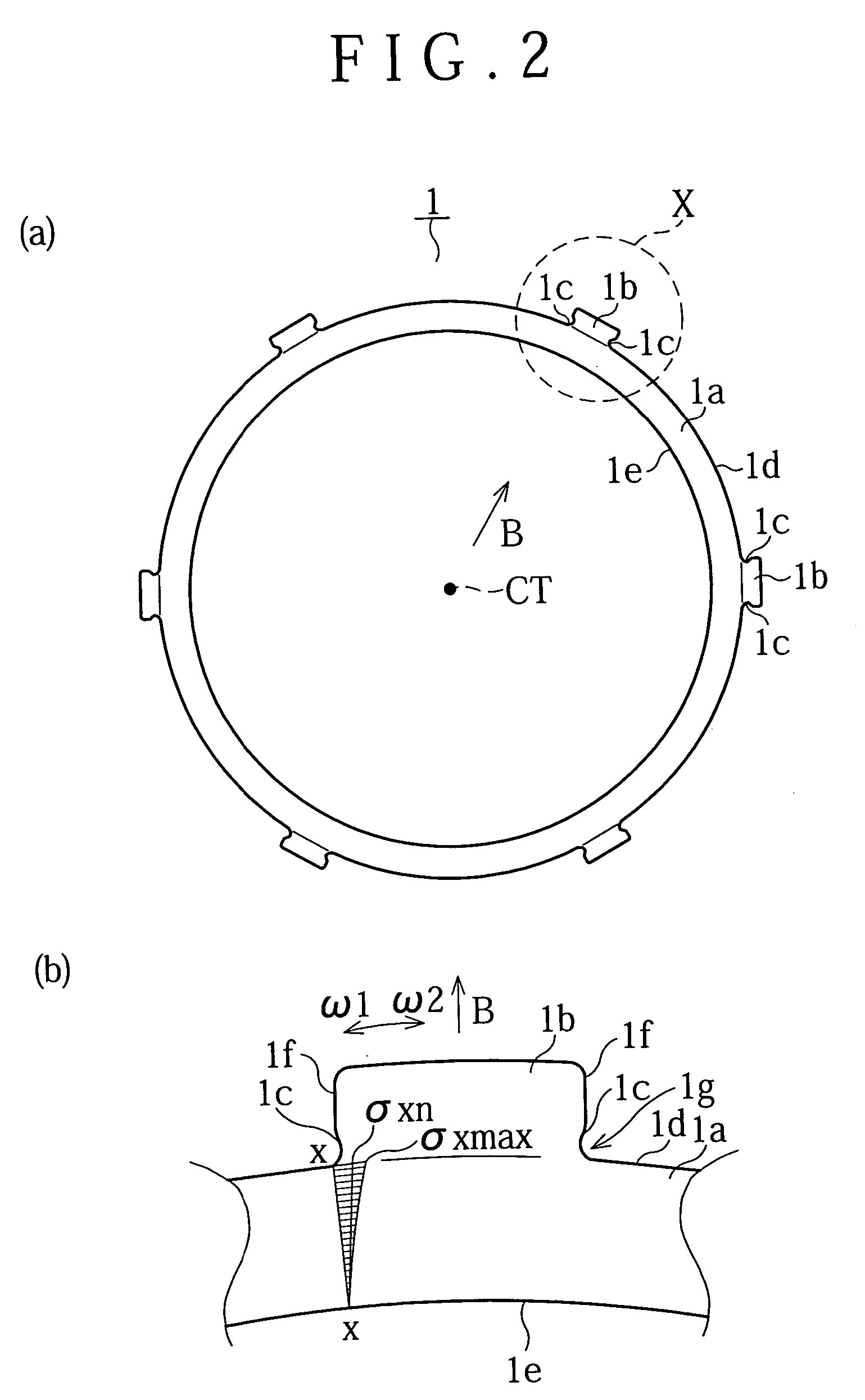

[0024] Hereinafter, an embodiment according to the present invention will be described with reference to the drawings. Firstly, an example of an automatic transmission to which the present invention is applied will be described briefly with reference to FIG. 1. As shown in FIG. 1, a belt-type continuously variable transmission (CVT) 50 is provided with, for example, an input shaft 3 and a pulley mechanism. Drive rotation is input from an engine to the input shaft 3 through a torque converter (not shown) or the like. The pulley mechanism includes a metal belt (not shown) held between a primary pulley 5 and a secondary pulley (not shown). The primary pulley 5 is supported by a transmission case 4 (a member on the outer periphery) through a ball bearing 7. The rotational speed of the primary pulley 5 is changed continuously by altering the pulley width, and the rotation as changed is output to the drive wheels through the secondary pulley. The belt-type CVT 50 has a forward / reverse swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com