Physical information acquisition method, a physical information acquisition apparatus, and a semiconductor device

a technology of physical information acquisition and acquisition apparatus, which is applied in the direction of color television details, television systems, radio control devices, etc., can solve the problems of increasing the length of the control line for controlling the reading of pixel signals, increasing the load imposed on the driver connected to the control line, and increasing the skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

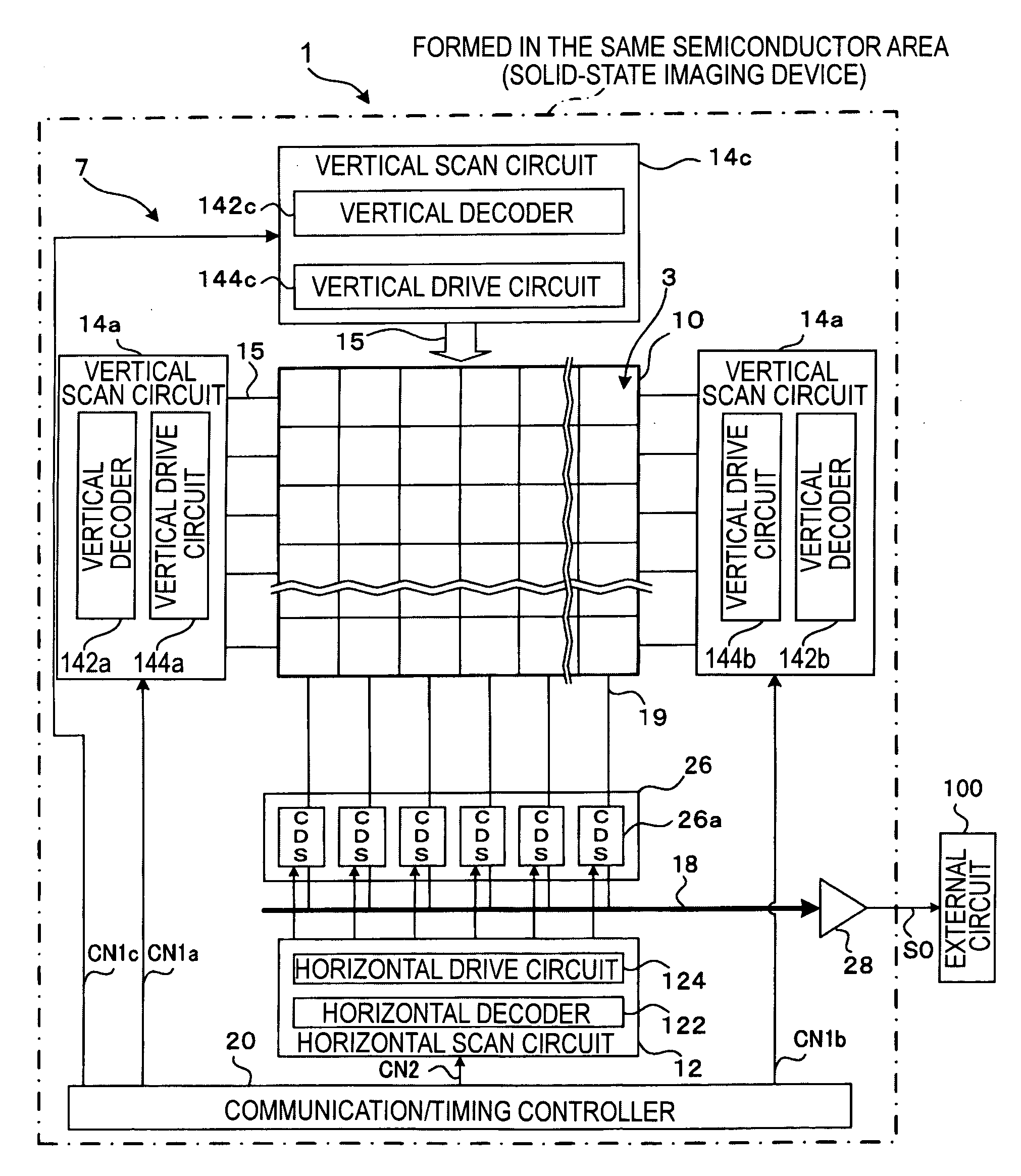

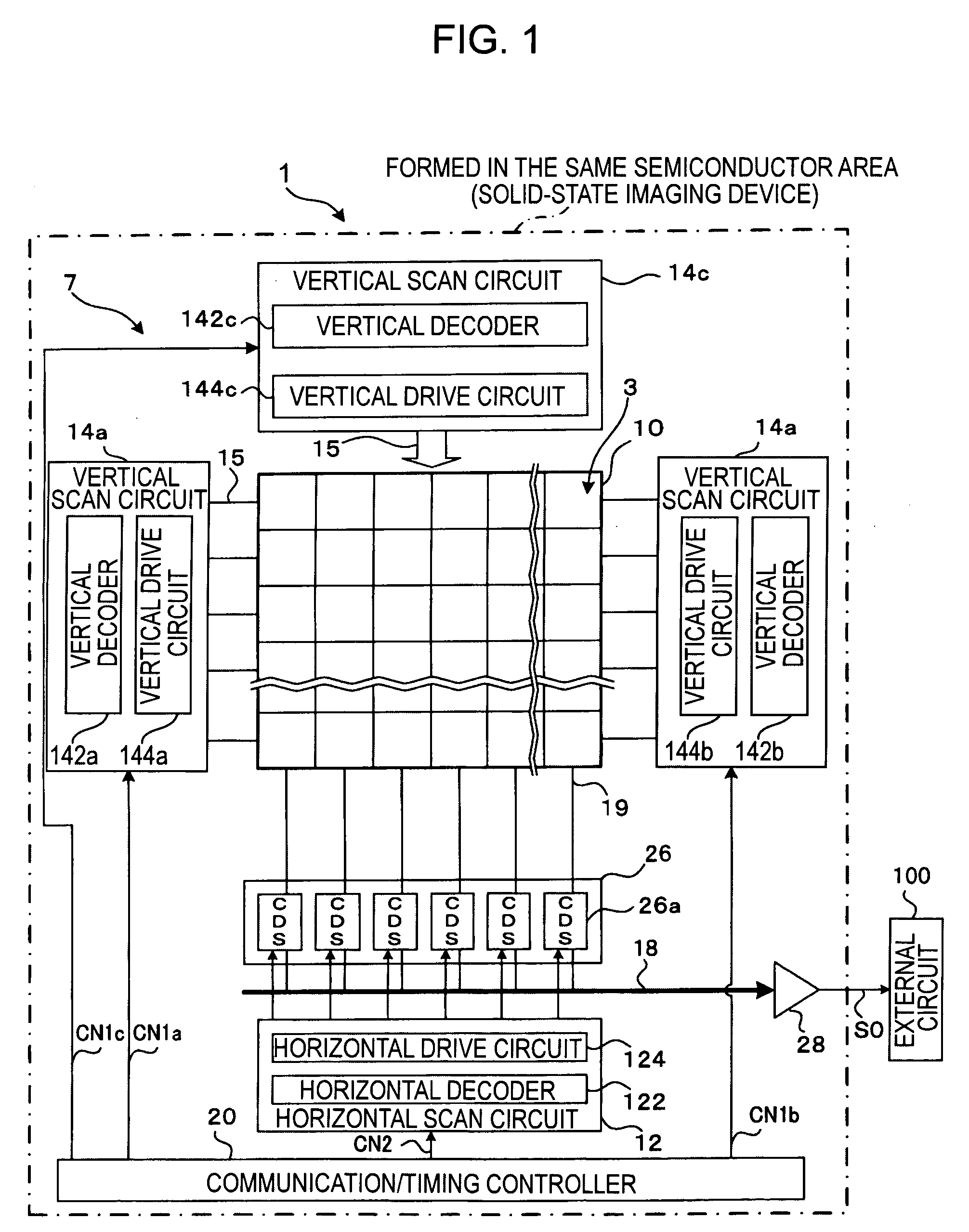

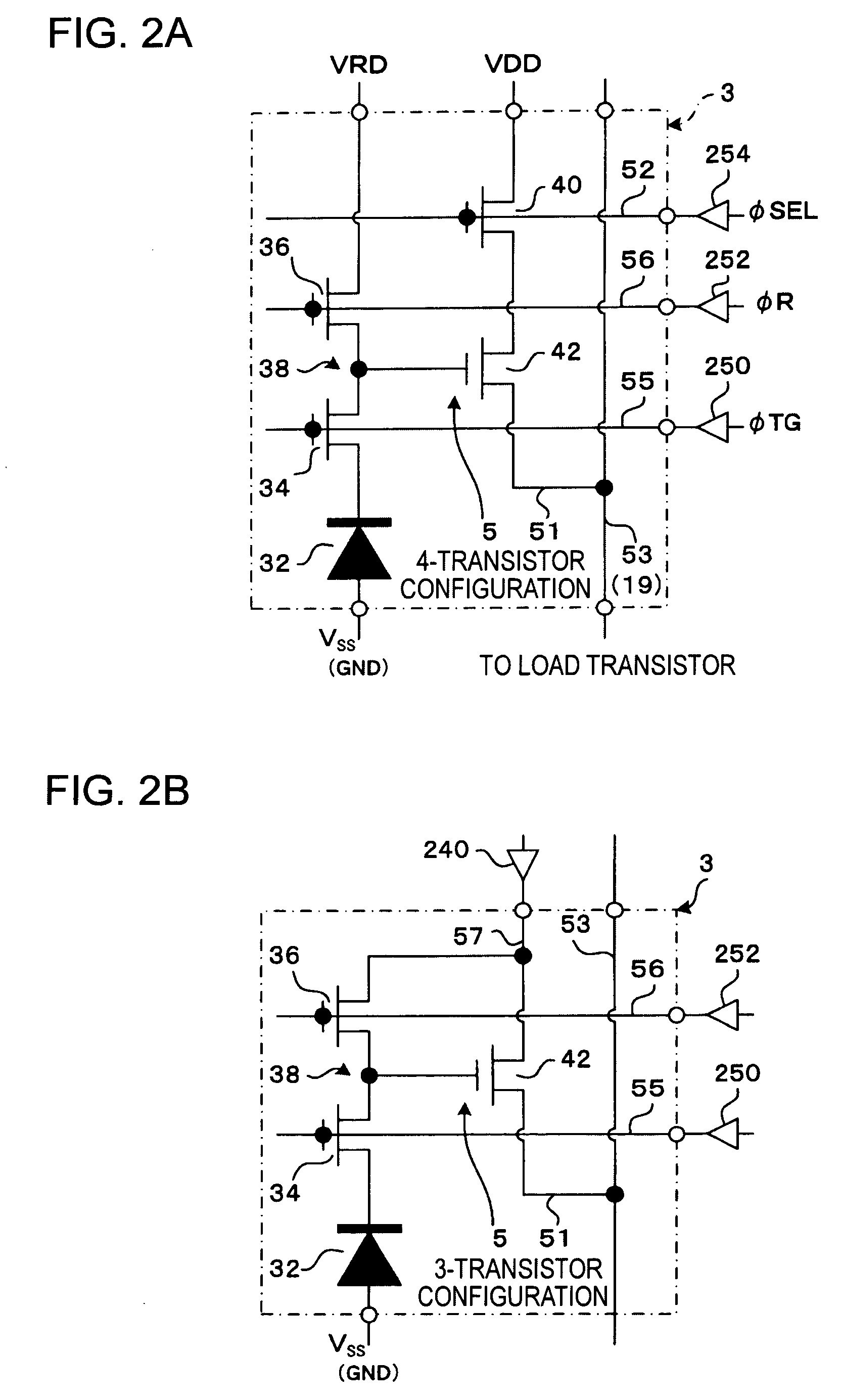

first embodiment

[0101]FIG. 3 shows a manner in which driving buffers are disposed so as to reduce skew (hereinafter, the technique will be referred to as a skew reduction layout technique) according to a first embodiment of the invention. FIG. 4 shows a comparative example in which driving is performed at one end, and FIG. 5 shows another comparative example in which driving is performed at both ends.

[0102] When a vertical driving circuit 144 (that is, a driving buffer BF) is disposed at only one side of the pixel array part 10 as in the case of the configuration shown in FIG. 4(A), the load increases as the number of pixels is increased to achieve higher resolution. The increase in the load results in an increase in the difference in reading time between a pixel located close to the driving buffer and a pixel located far from the driving buffer. This can make it difficult to correctly read pixel signals, and can cause shading or noise.

[0103] If the total line resistance is denoted by R and the t...

second embodiment

[0119]FIG. 7 shows a skew reduction layout technique according to a second embodiment of the invention. In this second embodiment, two ends of the control line are not used as original driving points, but original driving points are set at three dividing points of the control line such that points farthest from the respective driving points within the range in which skew is to be suppressed are distributed substantially equally. Hereinafter, this driving method will be referred to as the “three-dividing-point equal driving method”.

[0120] To set three original driving points such that points farthest from the respective original driving points within the range in which skew is to be suppressed are equally distributed, the distance between each point farthest from the corresponding original driving point is set to be ⅙ of the total length of the control line as shown in FIG. 7.

[0121] In this case, if the total line resistance is denoted as R and the total parasitic capacitance is de...

third embodiment

[0125]FIG. 8 shows a skew reduction layout technique according to a third embodiment of the invention. In this third embodiment, in addition to three original driving points on the control line two of which are located at points whose distance from a closer end of the control line is ¼ of the total length of the control line and the other one of which is located at the center of the control line, original driving points are set at two respective end points of the control line. Hereinafter, this driving method will be referred to as the “both-end and three-dividing-point equal driving method”.

[0126] In this case, as shown in FIG. 8, if the total line resistance is denoted as R and the total parasitic capacitance is denoted as C, the line resistance and the parasitic capacitance at the points farthest from the respective original driving points are respectively given by R / 8 and C / 8, and thus the time constant τe in the “both-end and three-dividing-point equal driving method” is given...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com