Strength additives for tissue products

a tissue product and additive technology, applied in the field of tissue making and papermaking, can solve the problems of high sloughing in wet weather, difficult to put on or take off clothing, etc., and achieve the effect of improving strength properties and increasing tensile strength of paper products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

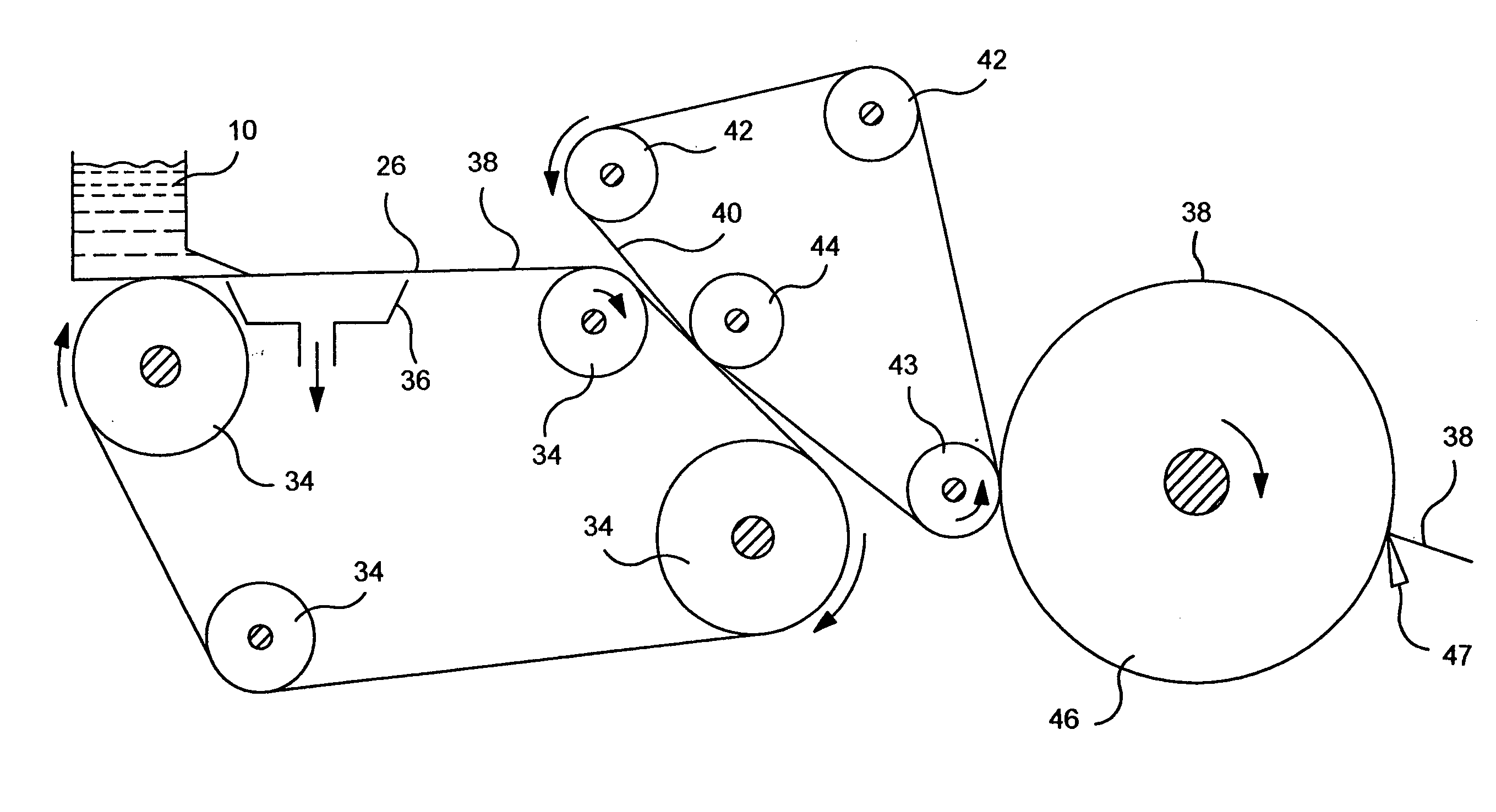

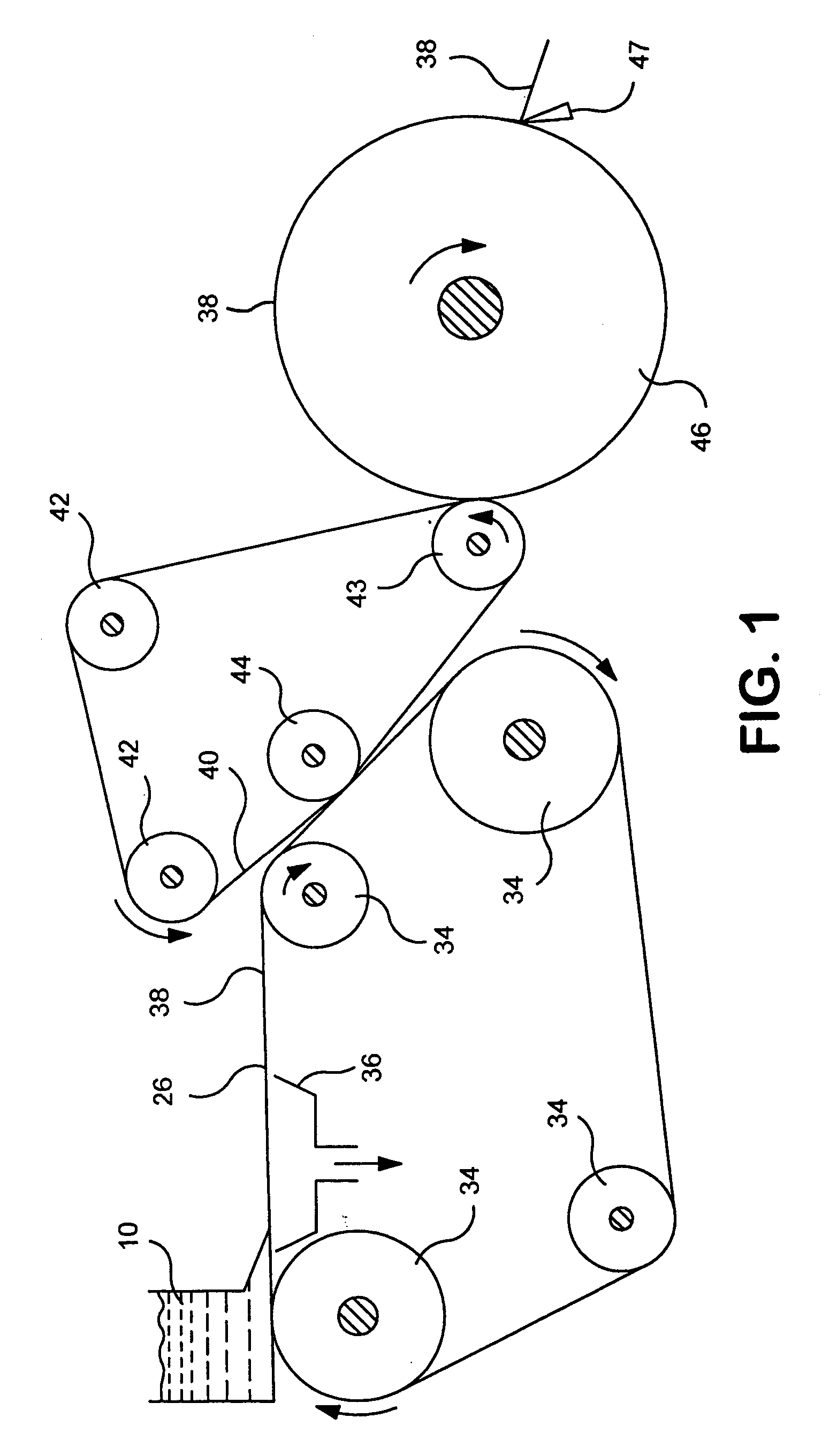

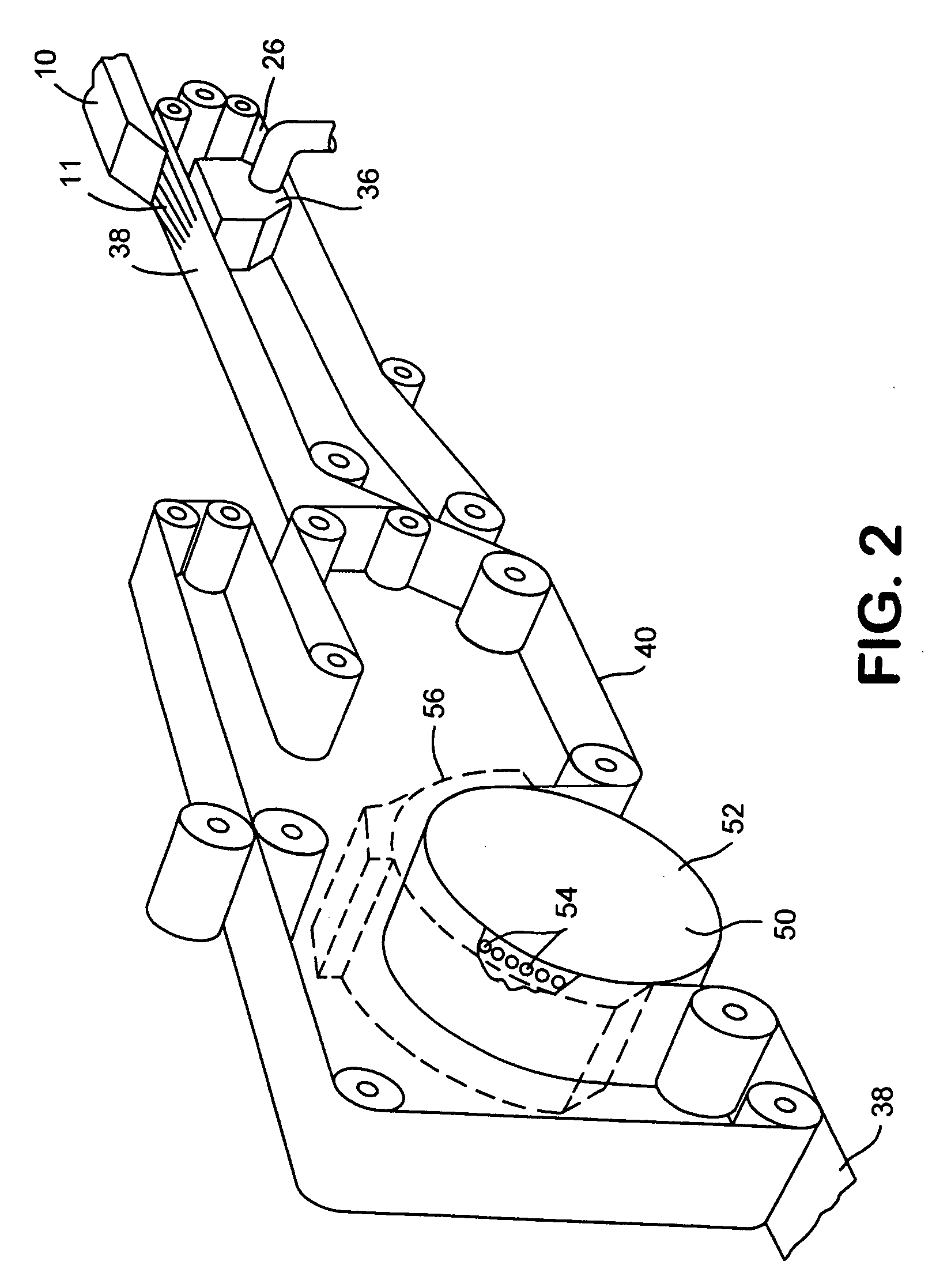

Method used

Image

Examples

example

[0073] A derivatized polyethylene oxide was formed having the following formula:

[0074] The polyethylene oxide used in this example had a molecular weight of 100,000 and incorporated 6 percent by weight silanol groups.

[0075] An aqueous solution containing 1.5 percent of the above silanol functional high molecular weight polyethylene oxide was prepared by dissolving the polymer in distilled water under high shear. The solution was placed in an air pressured spraying device and sprayed on an upcreped through-air dried bath base sheet containing no chemical. The base sheet had a basis weight of 18.5 lbs. per 2,880 sq. ft. Approximately 1 gram of solution was added per 0.2 grams of basesheet. The sheet was then dried in a convection oven at 120° C. for 5 minutes.

[0076] Treated samples and untreated samples of the base sheet were tested in the machine direction and the cross machine direction on a tensile strength tester. The samples were tested in the dry state and in the wet state. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com