Temporary driveway

a temporary and driveway technology, applied in the field of driveway construction, can solve the problems of insufficient construction traffic, difficult installation of concrete or blacktop on the finished surface of the driveway prior to construction, and inconvenient construction, so as to facilitate transportation, simplify and accelerate the construction process of the driveway, novel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] For the purposes of promoting an understanding of the principles of the invention, reference will now be made to the embodiments illustrated in the drawings and described in the following written specification. It is understood that no limitation to the scope of the invention is thereby intended. It is further understood that the present invention includes any alterations and modifications to the illustrated embodiments and includes further applications of the principles of the invention as would normally occur to one skilled in the art to which this invention pertains.

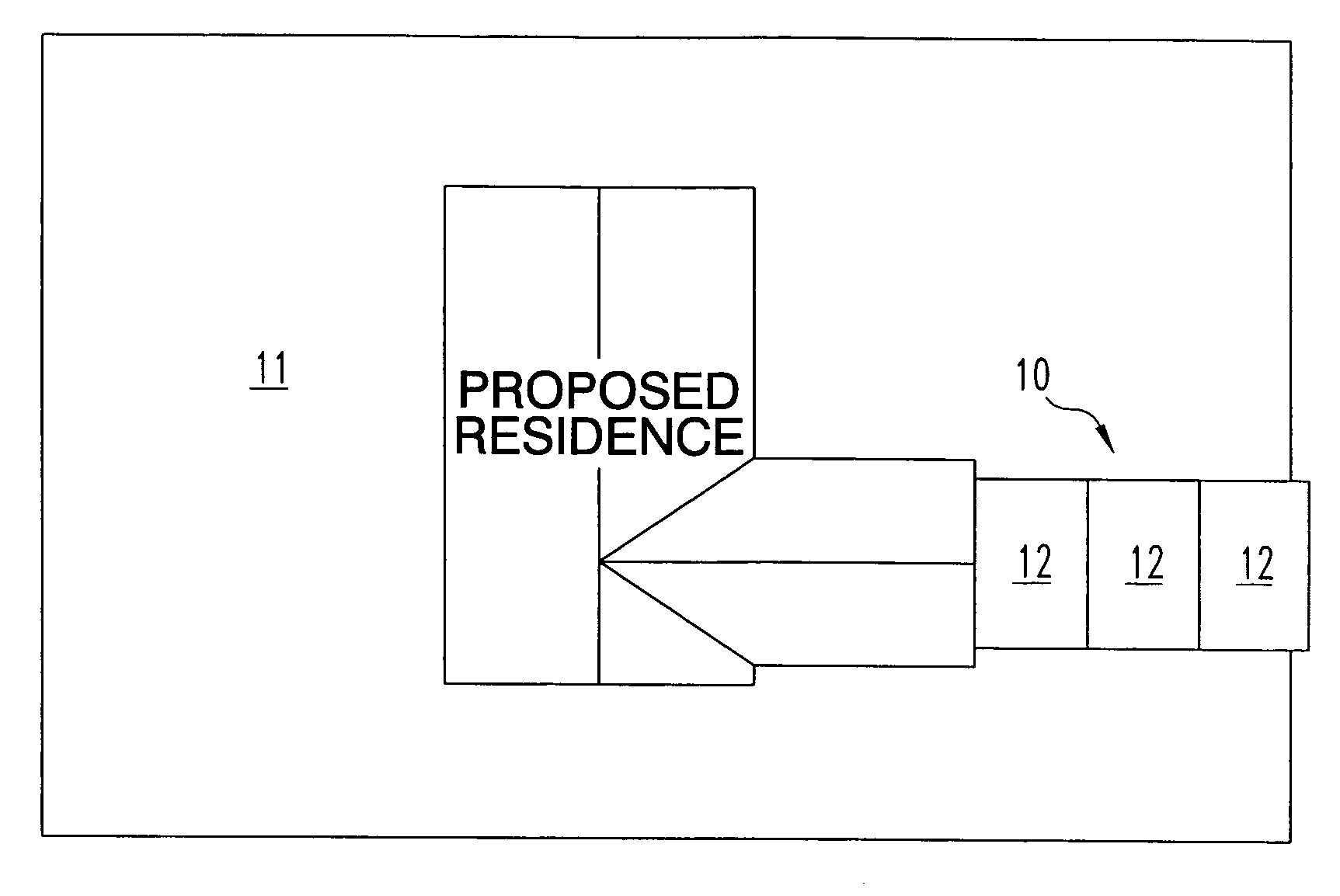

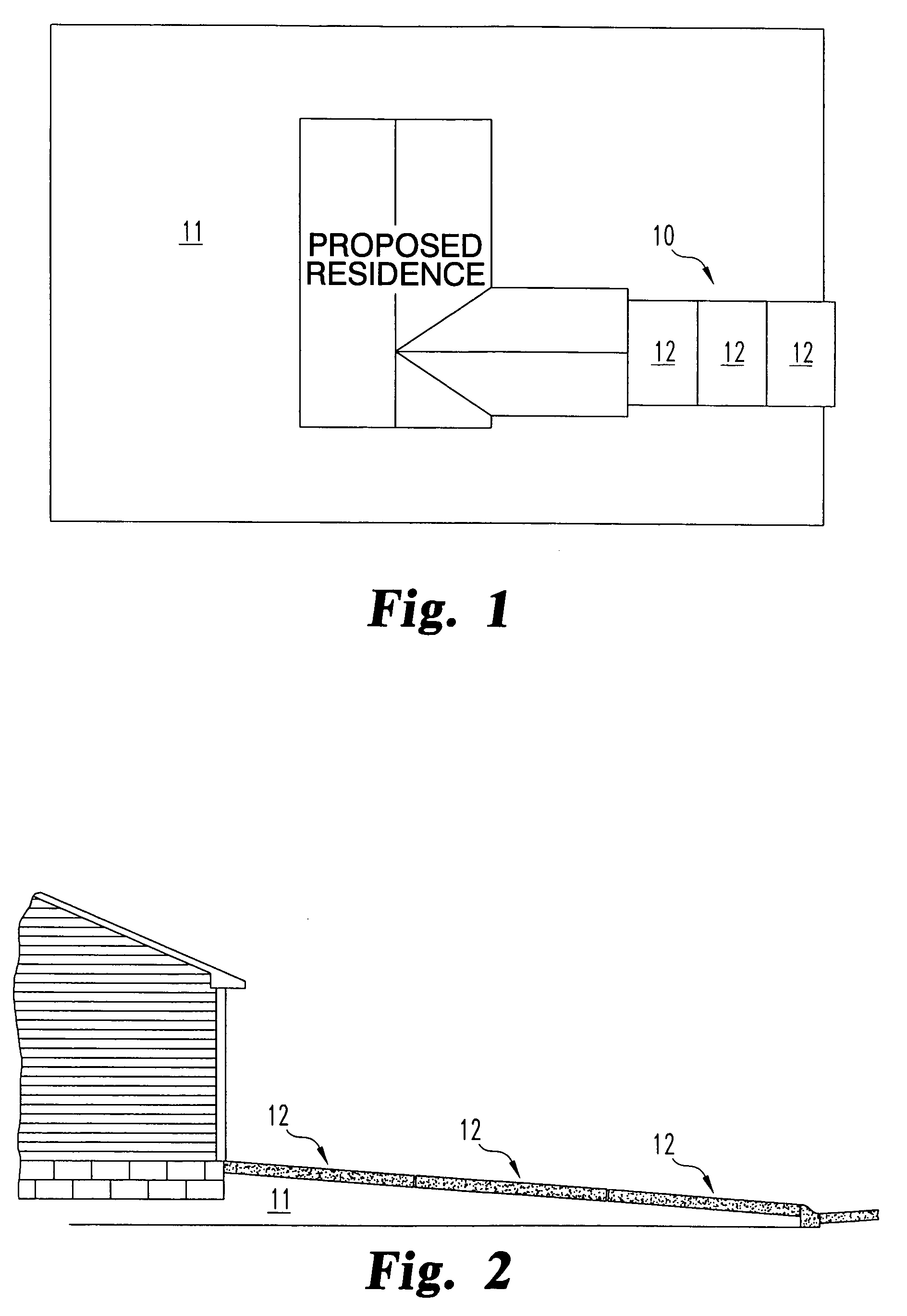

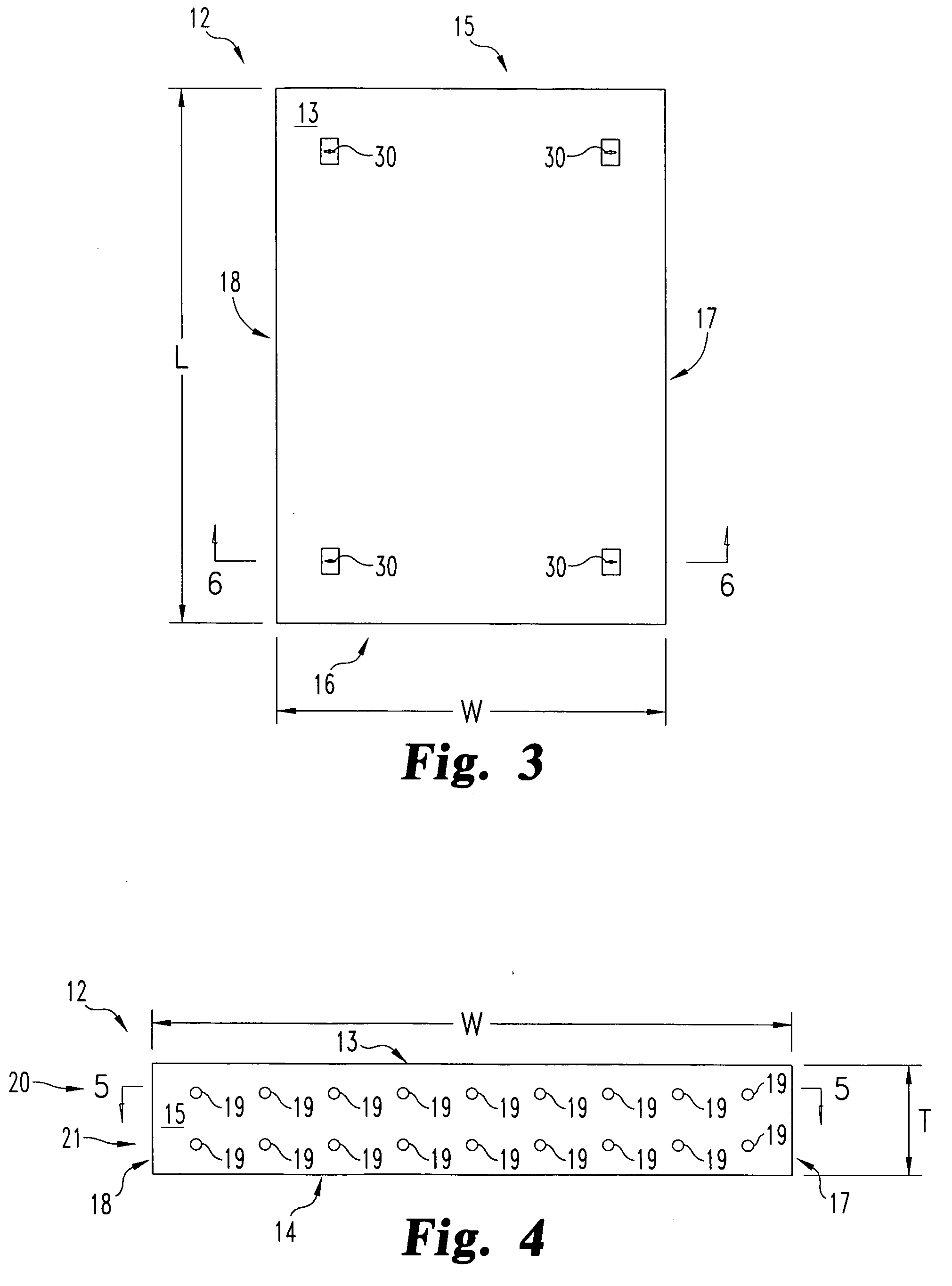

[0036] Referring to FIGS. 1 and 2, the present invention contemplates a temporary driveway 10 for placement on a new home construction site 11. According to the preferred embodiment, the temporary driveway 10 comprises one or more pre-cast planks 12 positioned to provide access to the new home site 11. The pre-cast planks 12 are formed of a castable or extrudable material having high surface hardness and high ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap