Gas turbine combustion chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

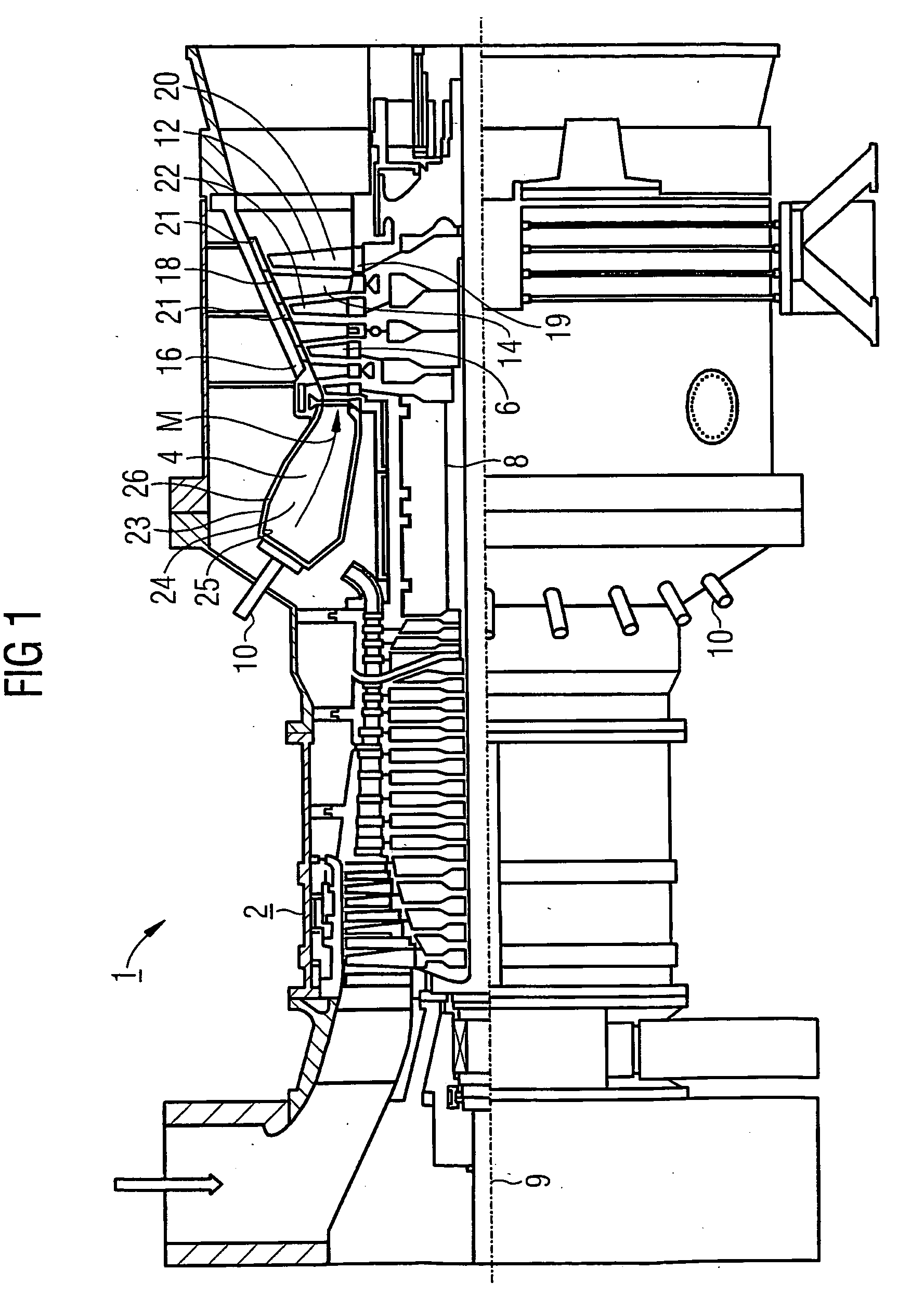

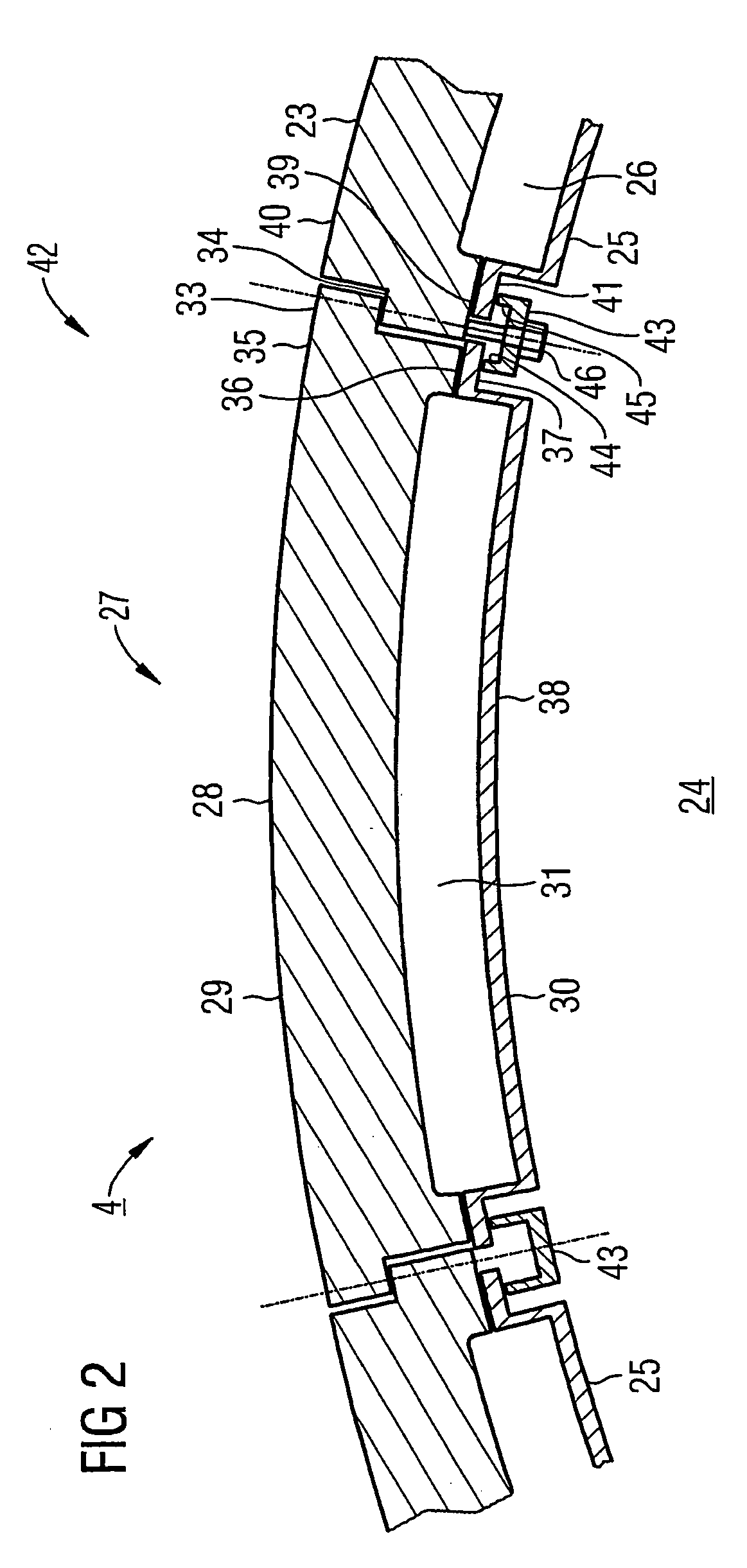

[0017] Identical parts are provided with the same reference characters in both figures.

[0018] The gas turbine 1 according to FIG. 1 has a compressor 2 for combustion air, a combustion chamber or a gas turbine combustion chamber 4 and a turbine 6 for driving the compressor 2 and a generator (not shown) or a machine. To this end, the turbine 6 and the compressor 2 are arranged on a common turbine shaft 8 known as a turbine rotor, to which the generator and / or the machine are also connected, and which is supported such that it can be rotated about its center axis 9.

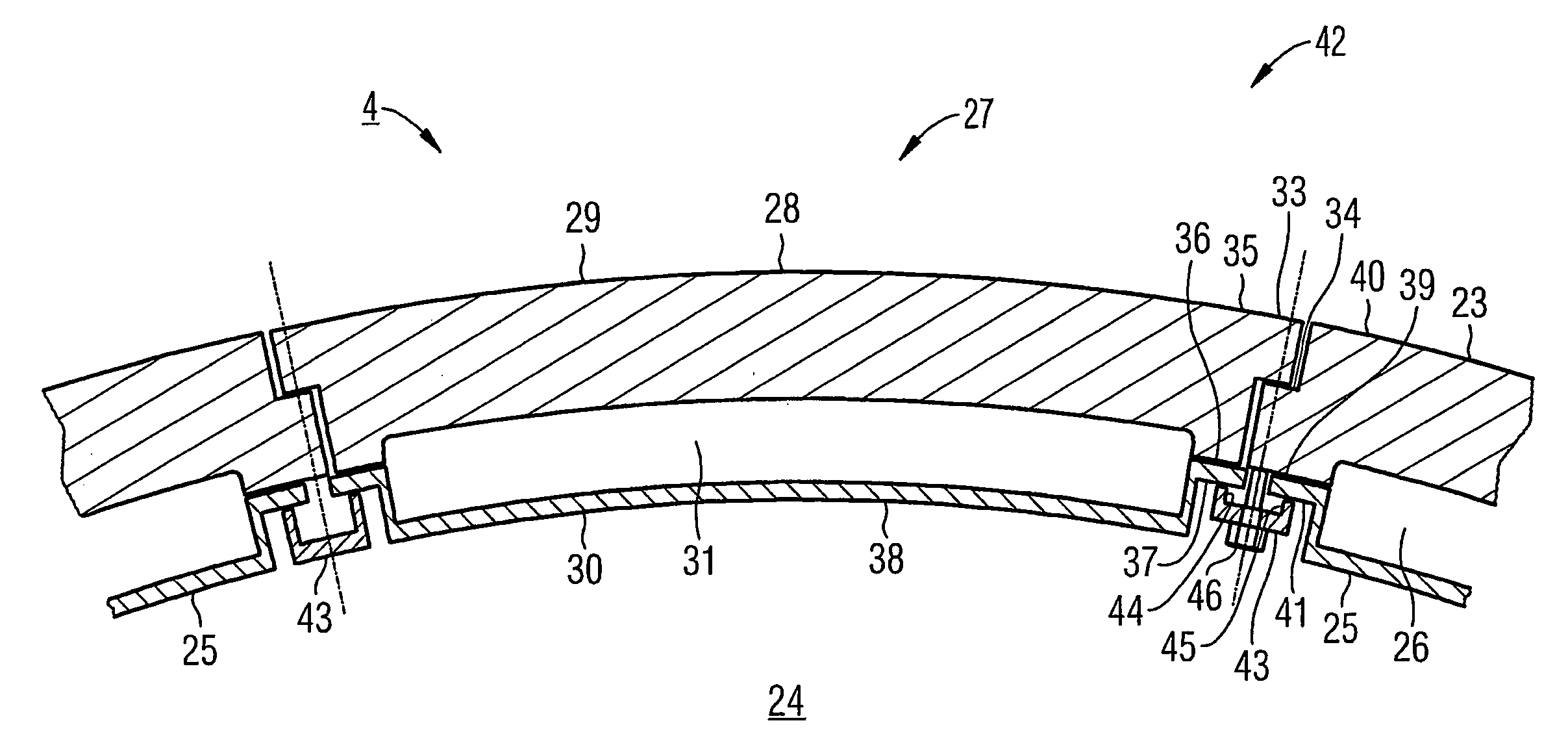

[0019] The combustion chamber 4 is equipped with a number of burners 10 for combusting a liquid or a gaseous fuel. Furthermore liner elements 25 are provided on its interior wall or combustion chamber wall 23.

[0020] The turbine 6 comprises a number of rotatable blades 12 connected to the turbine shaft 8. The blades 12 are arranged in a ring shape on the turbine shaft 8, thus forming a number of rows of blades. The turbine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com