Electrochemical processing apparatus and method

a processing apparatus and electrochemical technology, applied in the field of electrochemical processing apparatus and method, can solve the problems of increasing the number of steps, increasing the cost, and difficulty in removing the protective film after the process, and achieve the effect of processing more uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

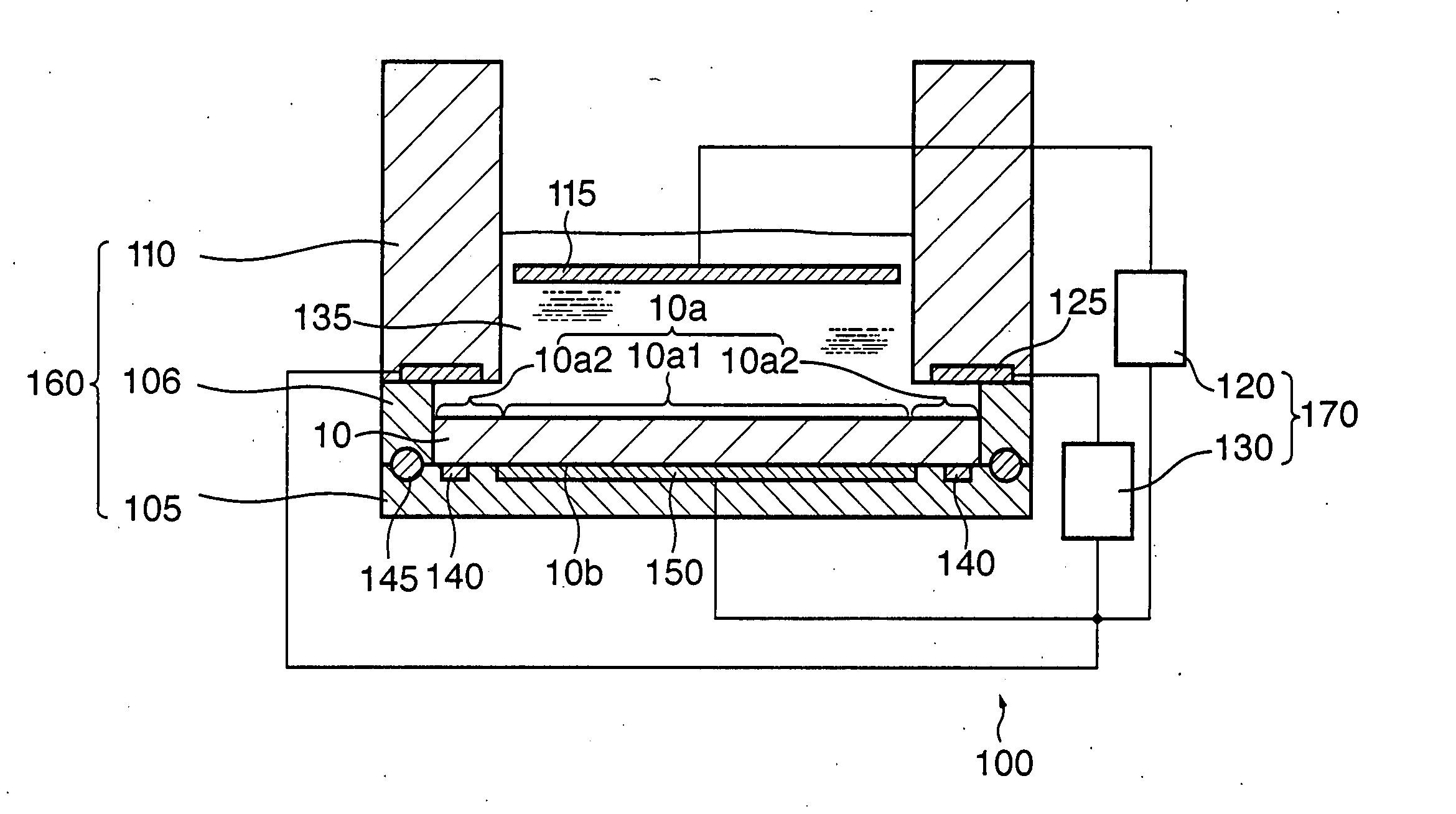

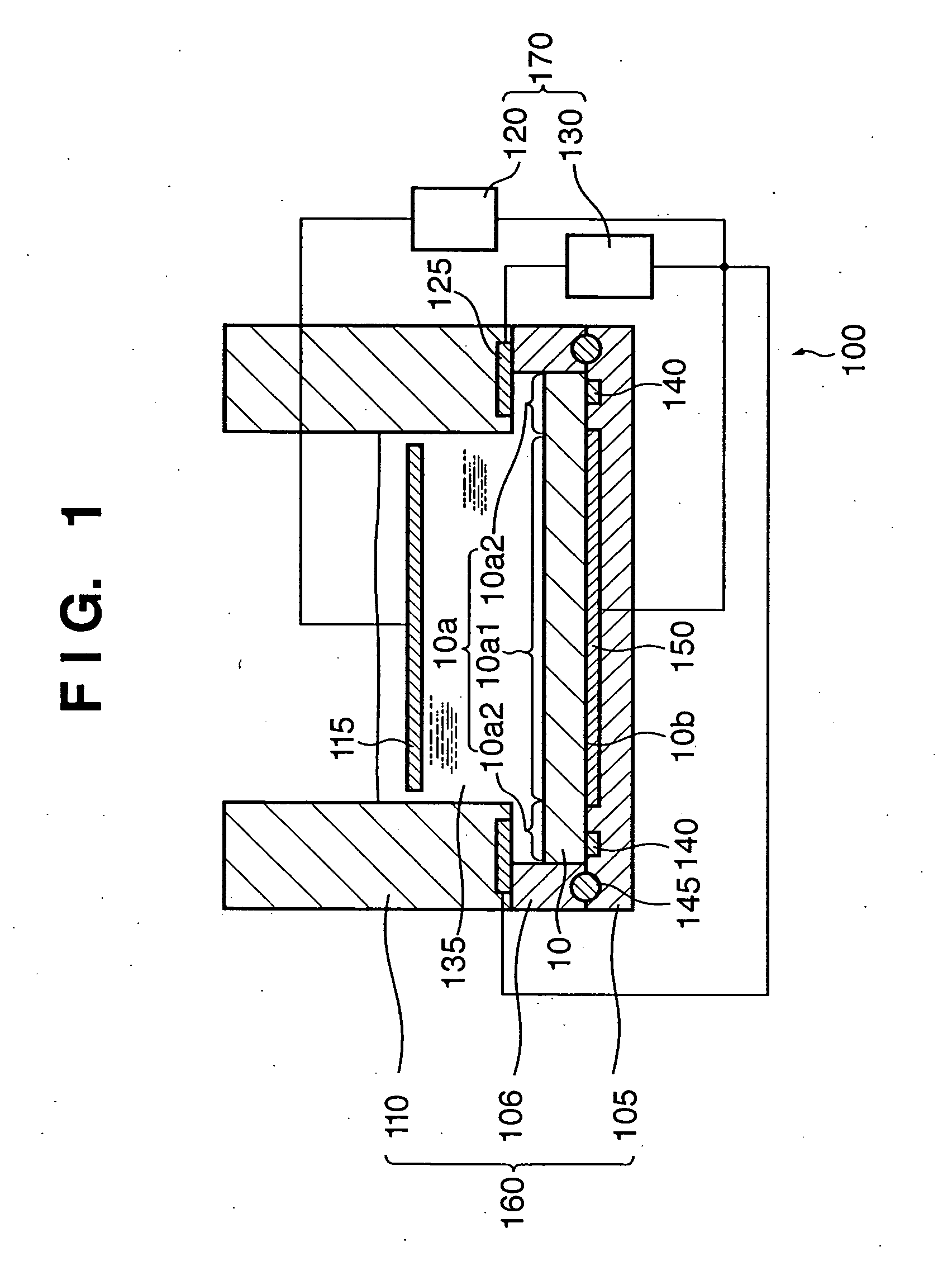

[0025]FIG. 1 is a view showing the structure of a processing apparatus according to the first embodiment of the present invention. A processing apparatus 100 shown in FIG. 1 is configured to electrochemically process part of a first surface 10a of a substrate (e.g., a silicon substrate) 10 which serves as a member having the first surface 10a and a second surface 10b. An example of the electrochemical process can include a chemical process, plating, and electrolytic oxidation.

[0026] The processing apparatus 100 has a support 140 which supports the member 10 to expose its first surface 10a, a first electrode (main electrode) 115 which is arranged to oppose a first portion 10a1 of the first surface 10a, a second electrode (auxiliary electrode) 125 which is arranged to oppose a second portion 10a2 of the first surface 10a, a third electrode 150 which applies a potential to the member 10 from the second surface 10b side, and a processing bath 160 which serves to fill the space defined ...

second embodiment

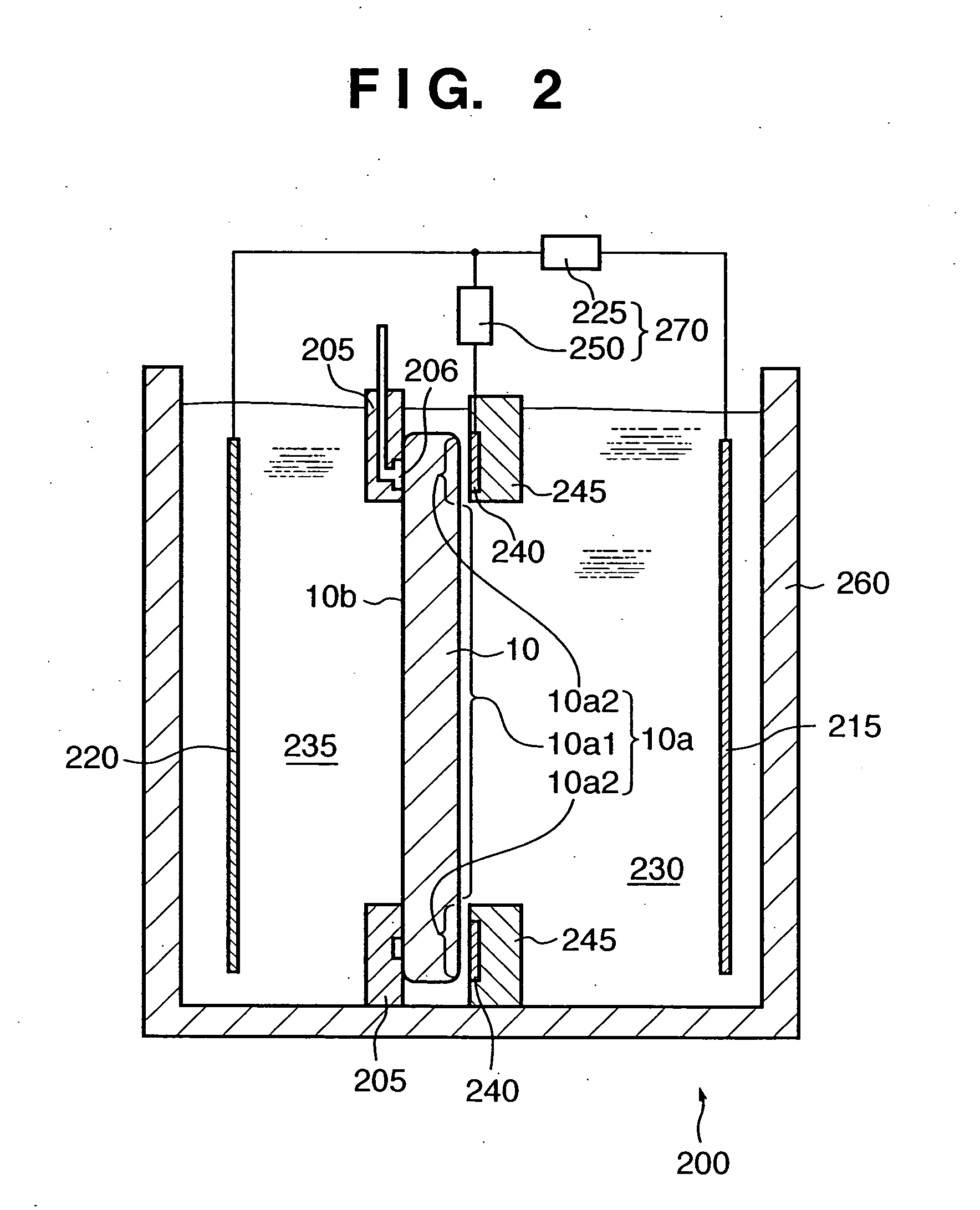

[0058]FIG. 2 is a view showing the structure of a processing apparatus according to the second embodiment of the present invention. A processing apparatus 200 shown in FIG. 2 is configured to electrochemically process part of a first surface 10a of a substrate (e.g., a silicon substrate) 10 which serves as a member having the first surface 10a and a second surface 10b. An example of the electrochemical process can include a chemical process, plating, and electrolytic oxidation.

[0059] The processing apparatus 200 has a support 205 which supports the member 10 to expose its first surface 10a, a first electrode (main electrode) 215 which is arranged to oppose a first portion 10a1 of the first surface 10a, a second electrode (auxiliary electrode) 240 which is arranged to oppose a second portion 10a2 of the first surface 10a, a third electrode 220 which is arranged to oppose the second surface 10b so as to apply a potential to the member 10 from the second surface 10b side, and a proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Distance | aaaaa | aaaaa |

| Electric field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com