Chemical mixing apparatus, system and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

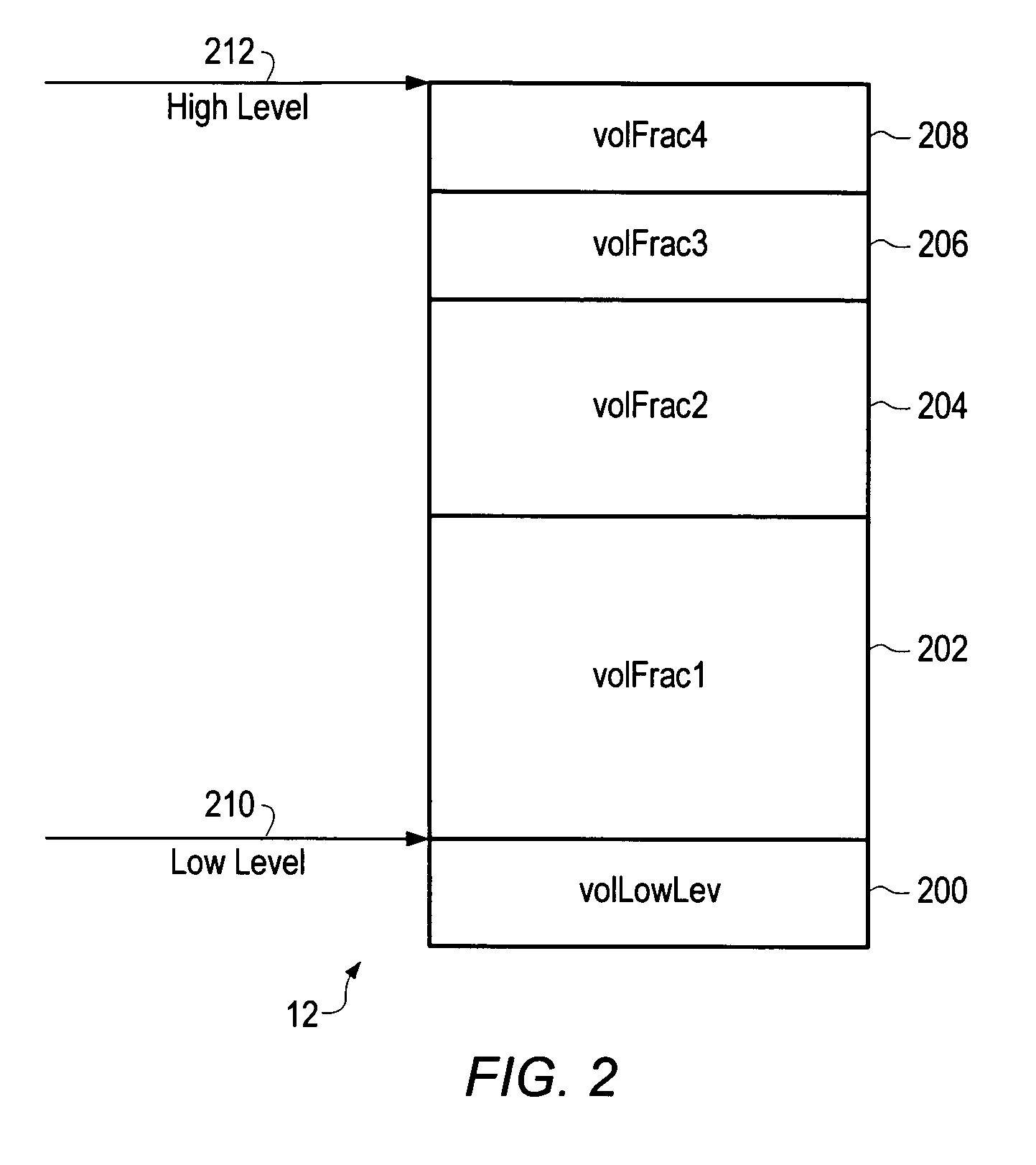

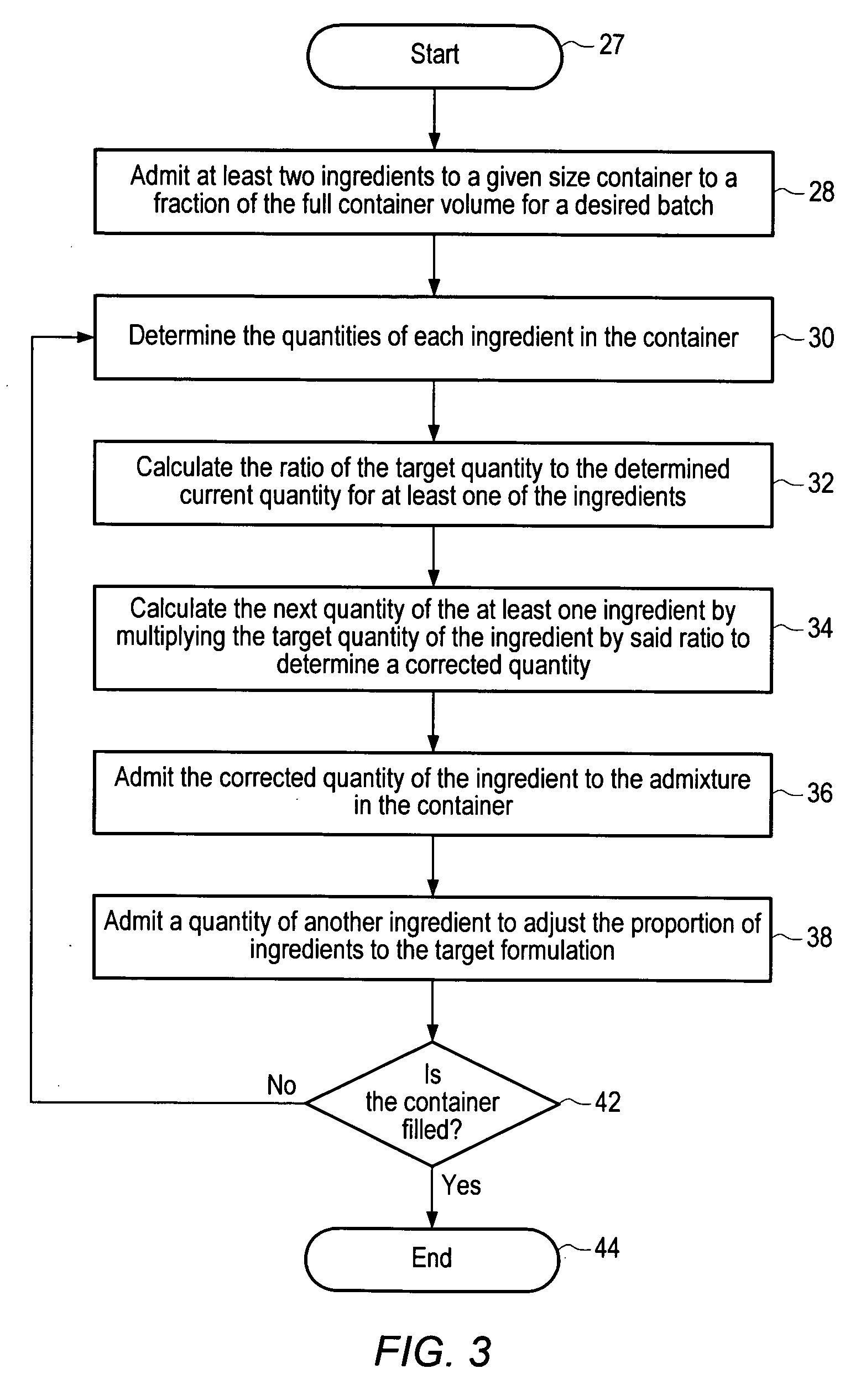

[0029] According to certain embodiments of the invention, there is provided a system and method of formulating a composition comprising at least two ingredients. The ingredients are admitted to a container to partially fill it. The quantities of the ingredient in the container are determined, and a ratio of a target quantity to the determined current quantity for at least one ingredient is calculated. The next quantity of that ingredient to be admitted to the admixture is calculated by multiplying the target quantity by the calculated ratio to determine a corrected quantity. The corrected quantity of the ingredient is admitted to the admixture, and a quantity of another ingredient is admitted to the admixture to adjust the proportion of ingredients to the target formulation. These steps may be repeated until a desired quantity of a predetermined composition is produced.

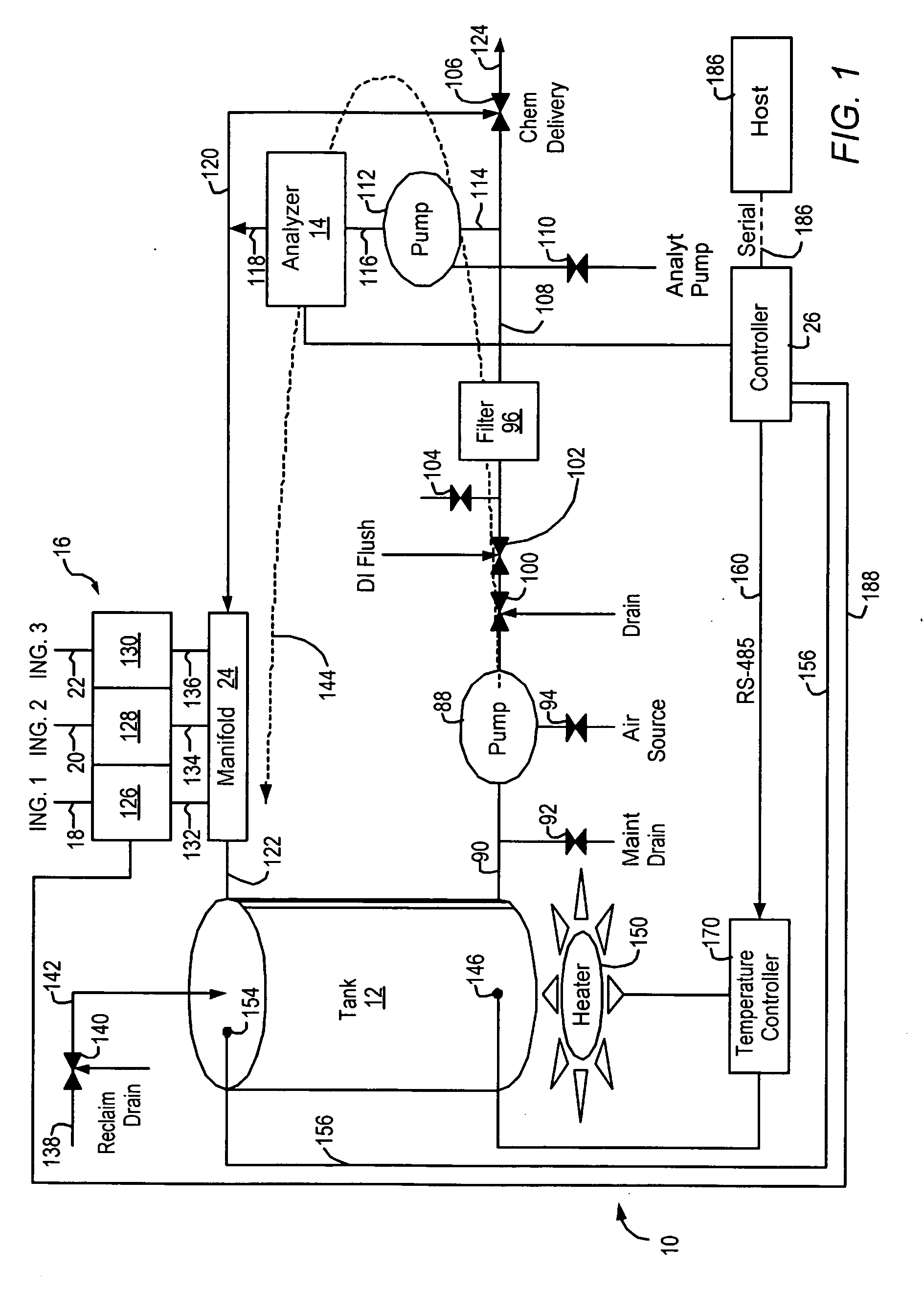

[0030] According to certain embodiments of the invention, there is provided a fractional fill mixing apparatus, sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com