Method and apparatus for measuring the diameter of a rod-shaped article

a technology of rod-shaped articles and measuring methods, which is applied in the direction of measurement devices, instruments, tobacco, etc., can solve the problems of inaccurate measurement of diameter, frequent out-of-roundness of rod-shaped articles, and insufficient precision of measuring diameter by only two cross-sectional axes, etc., to achieve the effect of extreme accurate diameter measurement of rod-shaped articles and suitable for diameter measuremen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

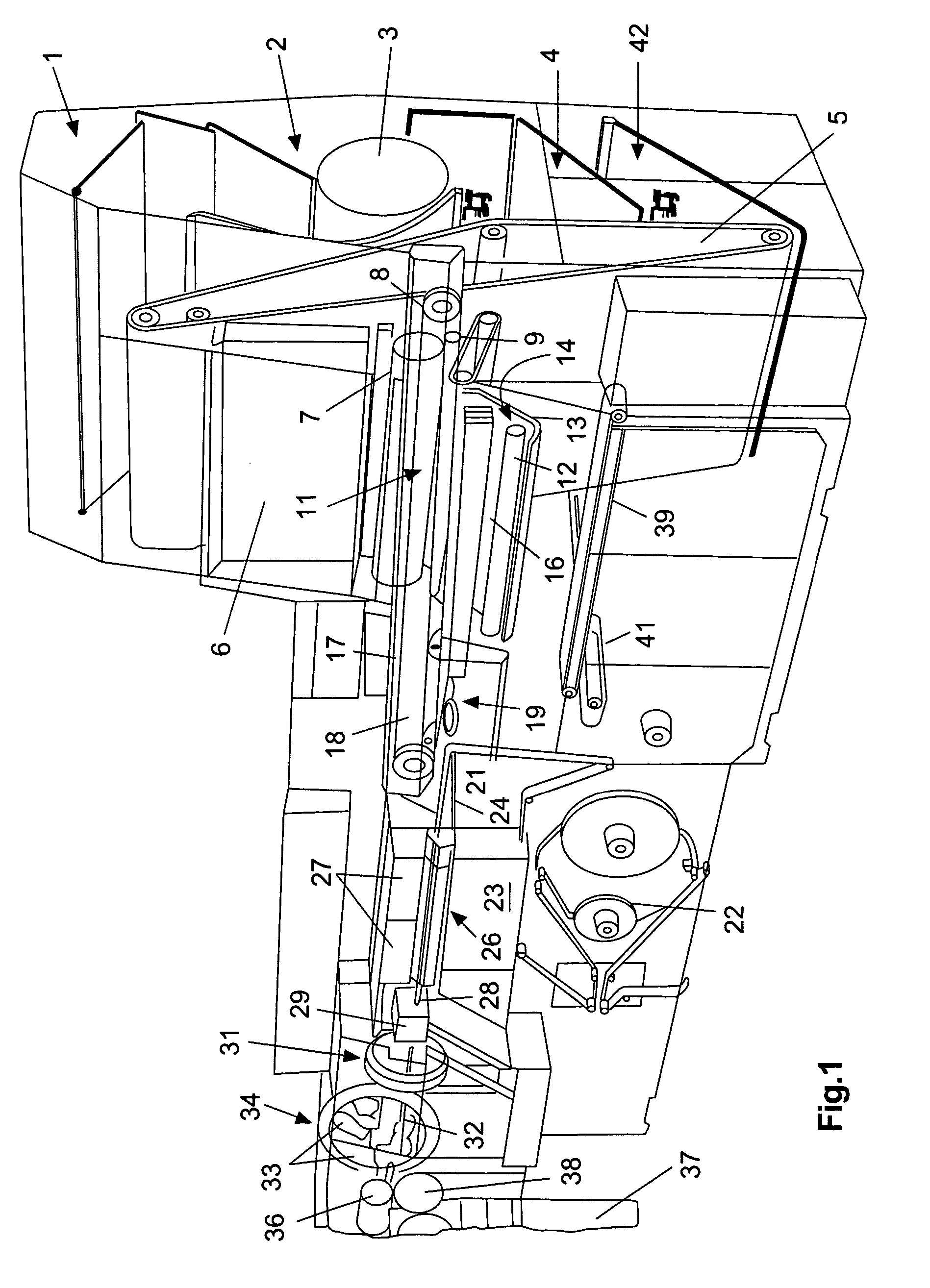

[0025]FIG. 1 shows a schematic, perspective view of a continuous cigarette rod machine of the type “PROTOS,” manufactured by the assignee of the present invention, in which the main components are visible. The design and function of this continuous cigarette rod machine are briefly described in the following.

[0026] An airlock 1 supplies a pre-distributing device 2 with batches of tobacco. In a controlled operation, a withdrawing roller 3 of the pre-distributing device 2 is used to supplement the tobacco in a storage container 4 from which a vertical conveyor 5 removes the tobacco. In a controlled operation, the vertical conveyor then feeds this tobacco to an accumulation chute 6. A pin roller 7 removes a uniform stream of tobacco from this accumulation chute 6 and a beater roller 8 then beats the tobacco out of the pins of the pin roller 7 and tosses the tobacco with a constant speed onto a circulating distributing web 9.

[0027] A fibrous tobacco fleece, formed in this way on the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com