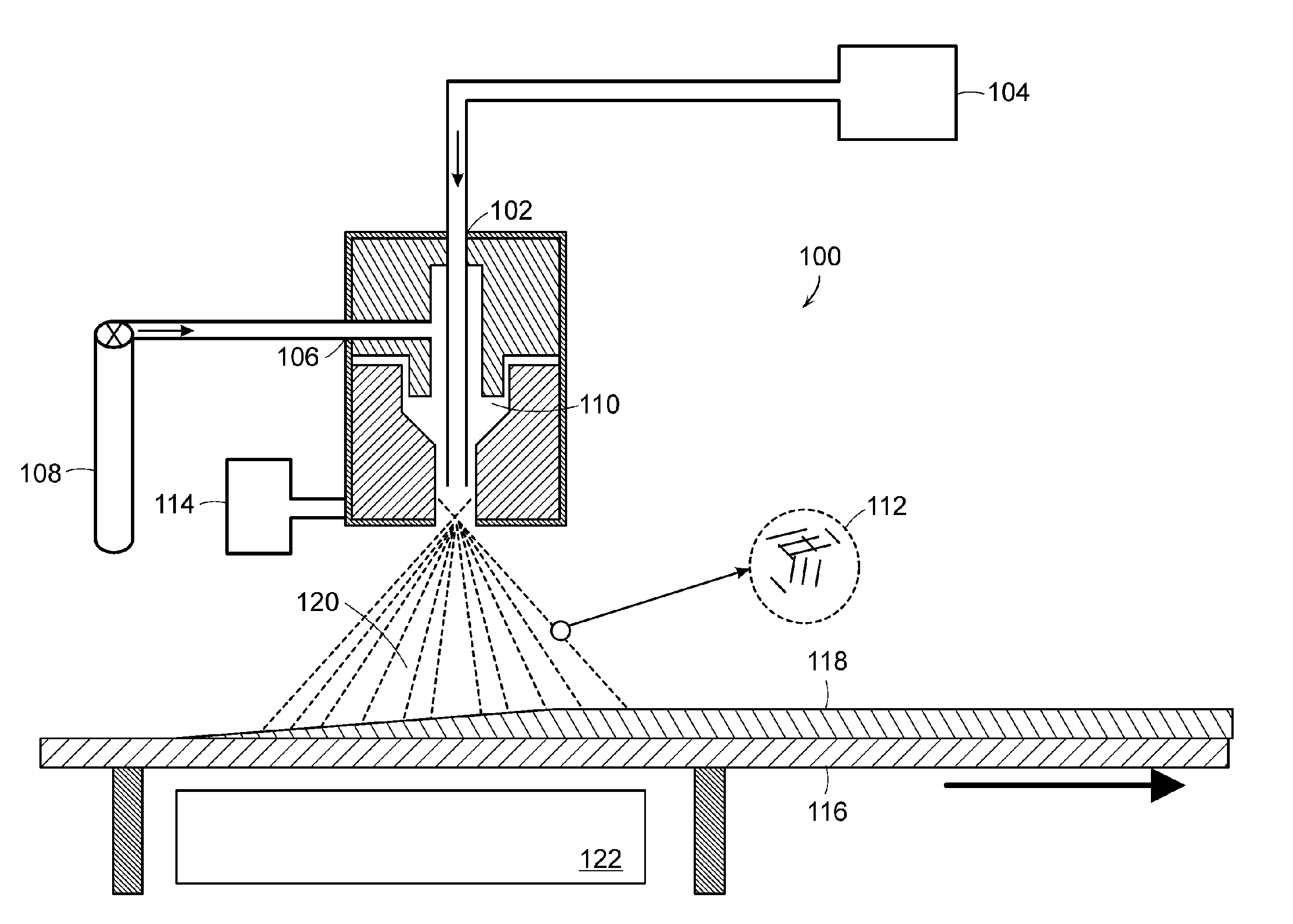

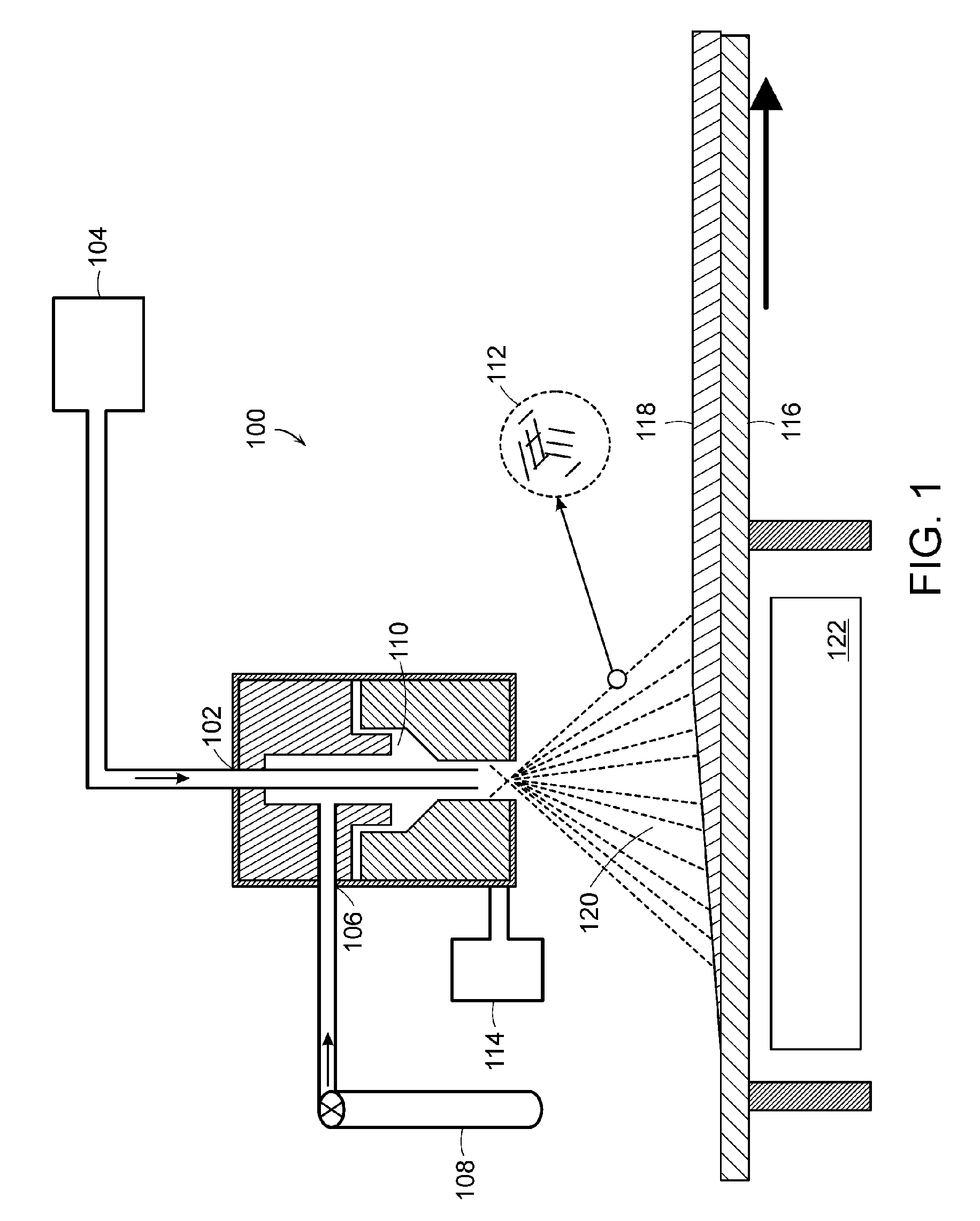

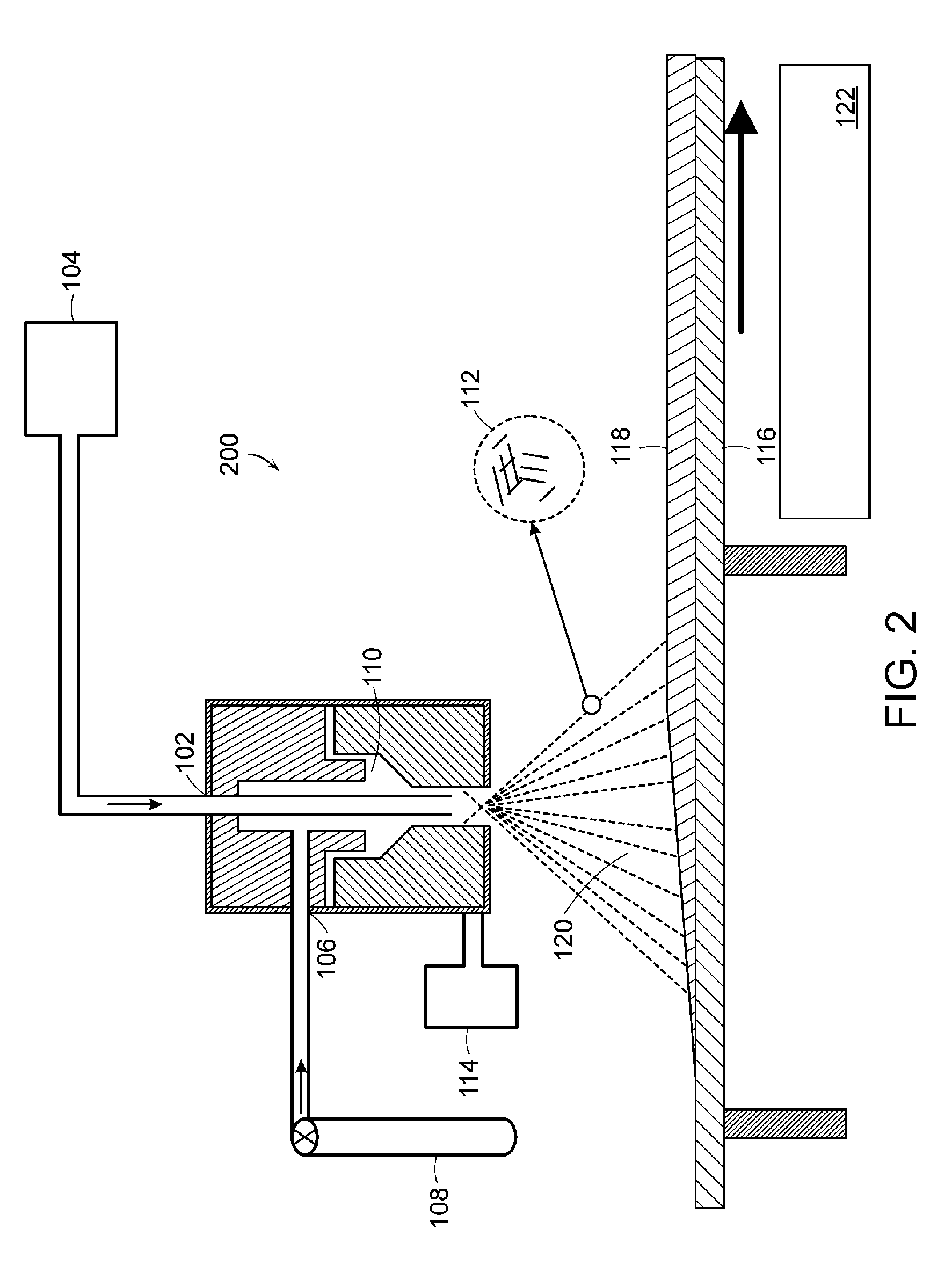

Spray deposition apparatus and methods for metal matrix composites

a technology of metal matrix composites and deposition apparatus, which is applied in the direction of wood working apparatus, metallic material coating process, special surfaces, etc., can solve the problems of increasing the complexity and functionality of semiconductor structures, and devices often have to dissipate large amounts of hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] While the present teachings are described in conjunction with various embodiments and examples, it is not intended that the present teachings be limited to such embodiments. On the contrary, the present teachings encompass various alternatives, modifications, and equivalents, as will be appreciated by those of skill in the art.

[0015] It should be understood that the individual steps of the methods of the present invention may be performed in any order and / or simultaneously as long as the invention remains operable. Furthermore, it should be understood that the apparatus of the present invention can include any number or all of the described embodiments as long as the invention remains operable.

[0016] Known heat sinks are commonly fabricated from metals, such as copper, molybdenum, tungsten and aluminum. A metal heat sink is often plated with nickel prior to attachment to a ceramic package at an elevated temperature. Alternatively, silver-filled adhesives, or other conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com