Aqueous ink, aqueous ink set, ink cartridge, ink-jet recording apparatus, ink-jet recording method, and image-forming method

a technology applied in the field of ink and ink, can solve the problems of large amount of excessive coloring material on the surface, insufficient image density, and increased amount of ink to be applied, and achieve excellent fixability, high image density, and good bleeding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

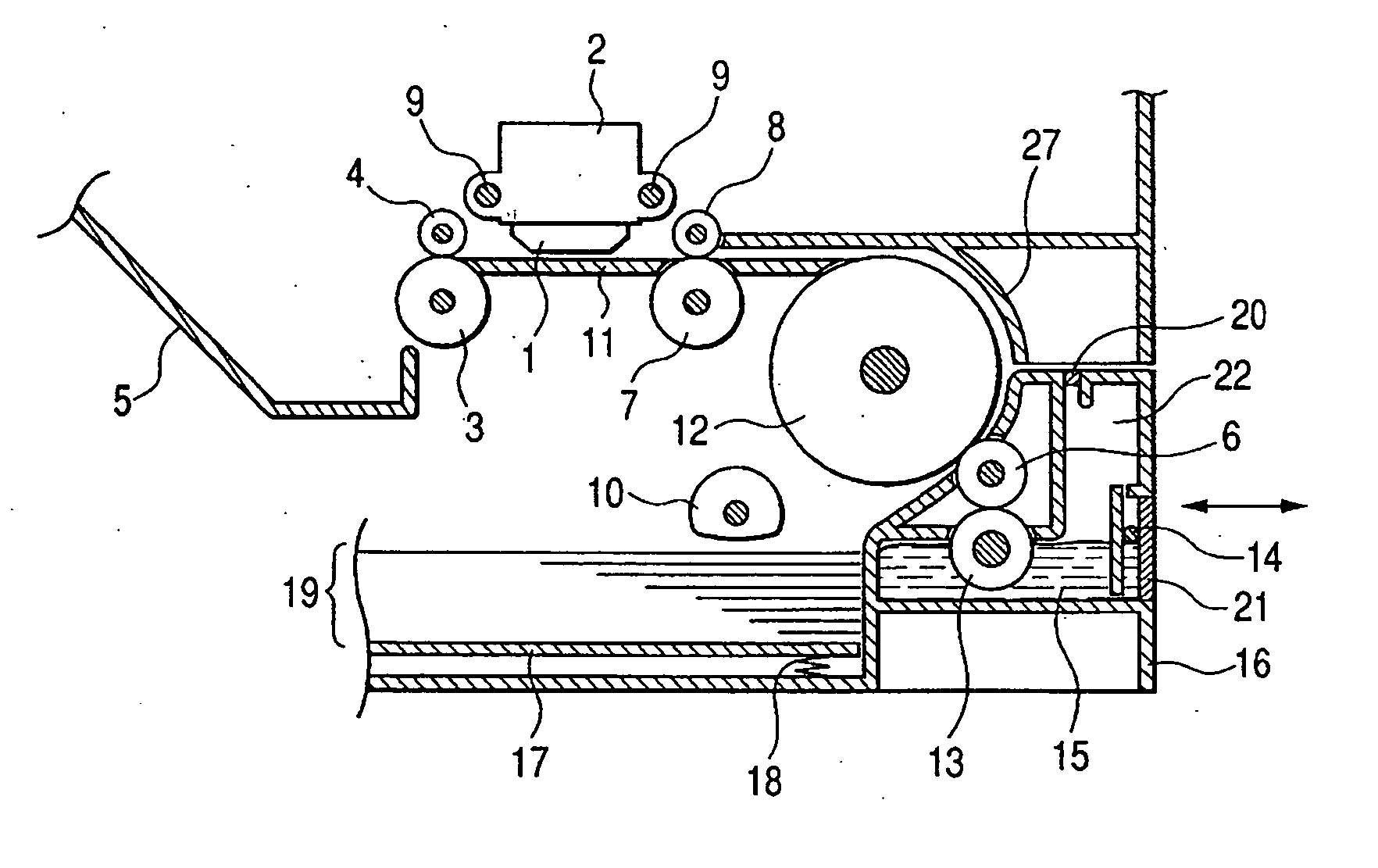

[0293] In Example 1, a recorded article was produced by using the inks BK1 and BK7, and a reaction liquid in combination. An apparatus having a mechanism shown in FIG. 1 with which a reaction liquid was applied to a recording medium by means of an applying roller was used to apply the reaction liquid to each of the above plain papers. After the reaction liquid had been fixed to the recording medium, the ink BK1 was mounted on a black ink position of an ink-jet recording apparatus BJF 900 (manufactured by CANON Inc.) to print a letter including a solid print portion measuring 2 cm×2 cm with a duty of 100%. Furthermore, the ink BK7 was mounted on a photocyan ink position of the ink-jet recording apparatus BJF900 (manufactured by CANON Inc.) to print, on each of the above gloss recording media to which no reaction liquid was applied, a solid print image measuring 5 cm×5 cm with its duty changed up to 100% in an increment of 10%.

example 2

[0294] In Example 2, a recorded article was produced in the same manner as that described above by using the inks BK2 and BK7, and a reaction liquid in combination. The ink BK2 was used for printing a letter on plain paper to which the reaction liquid had been applied, and the ink BK7 was used for printing a letter on a glossy recording medium.

example 3

[0295] In Example 3, a recorded article was produced in the same manner as that described above by using the inks BK3 and BK8, and a reaction liquid in combination. The ink BK3 was used for printing a letter on plain paper to which the reaction liquid had been applied, and the ink BK8 was used for printing a letter on a glossy recording medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com