Circuit connecting material, film-like circuit connecting material using the same, circuit member connecting structure, and method of producing the same

- Summary

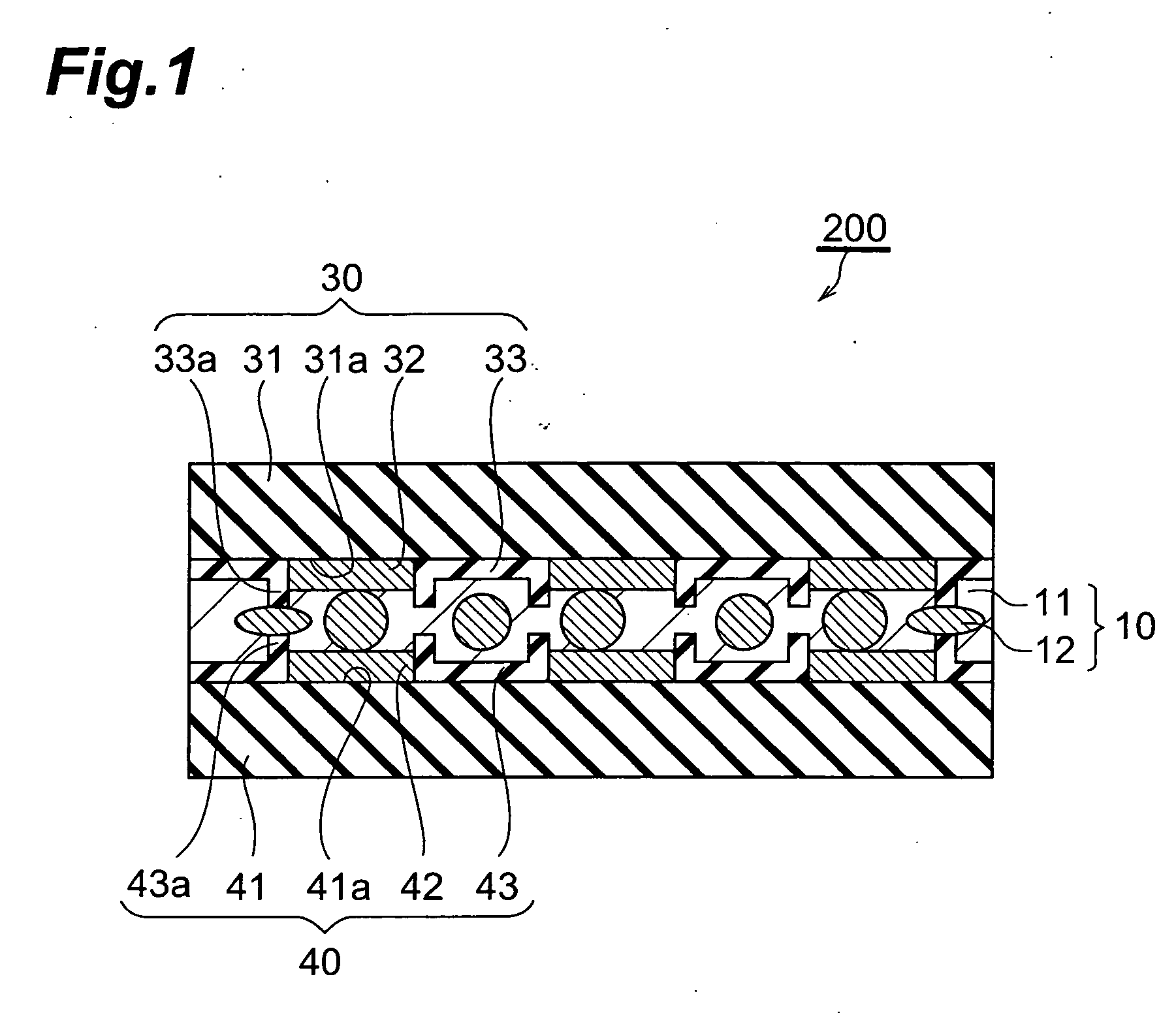

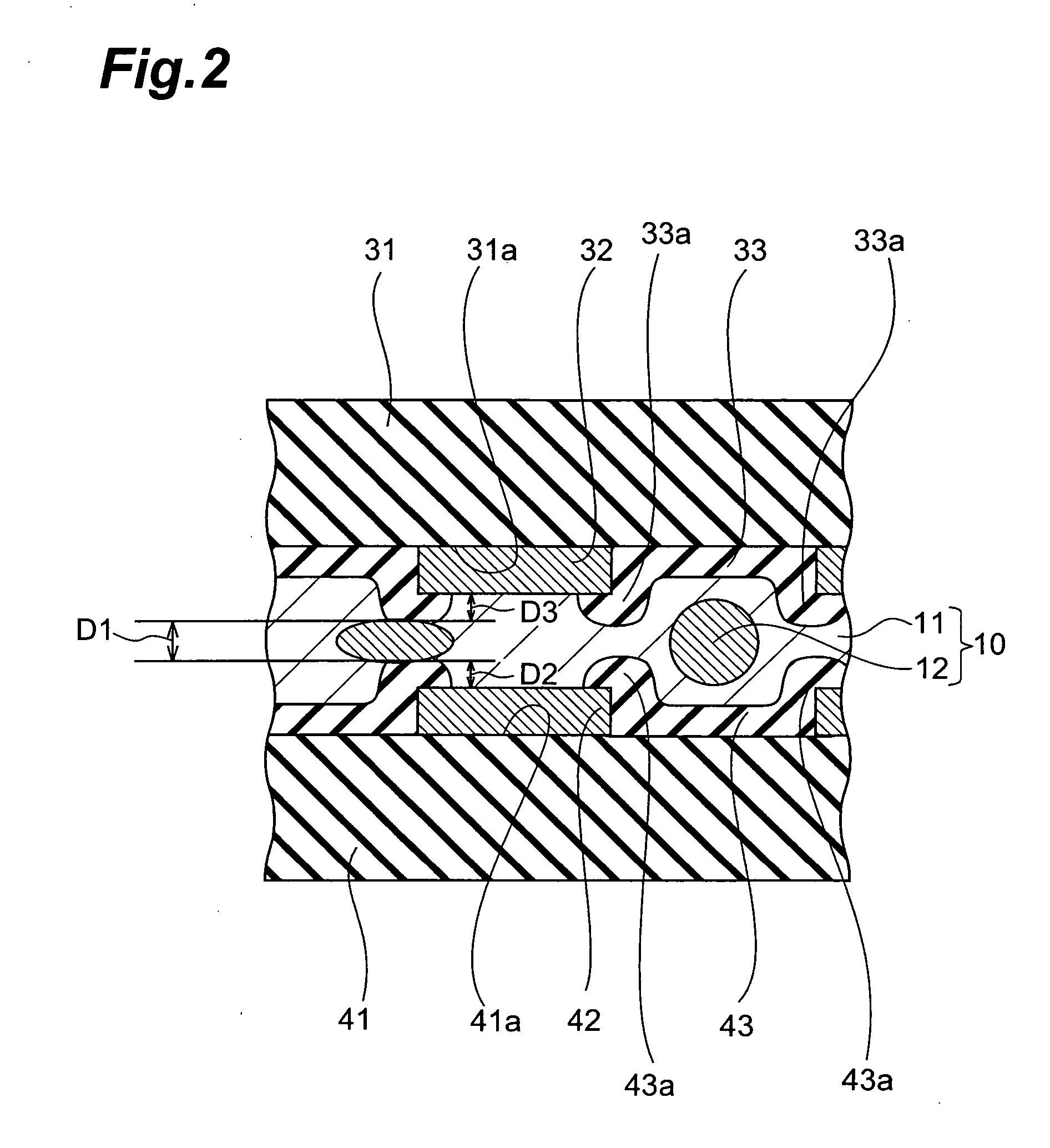

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

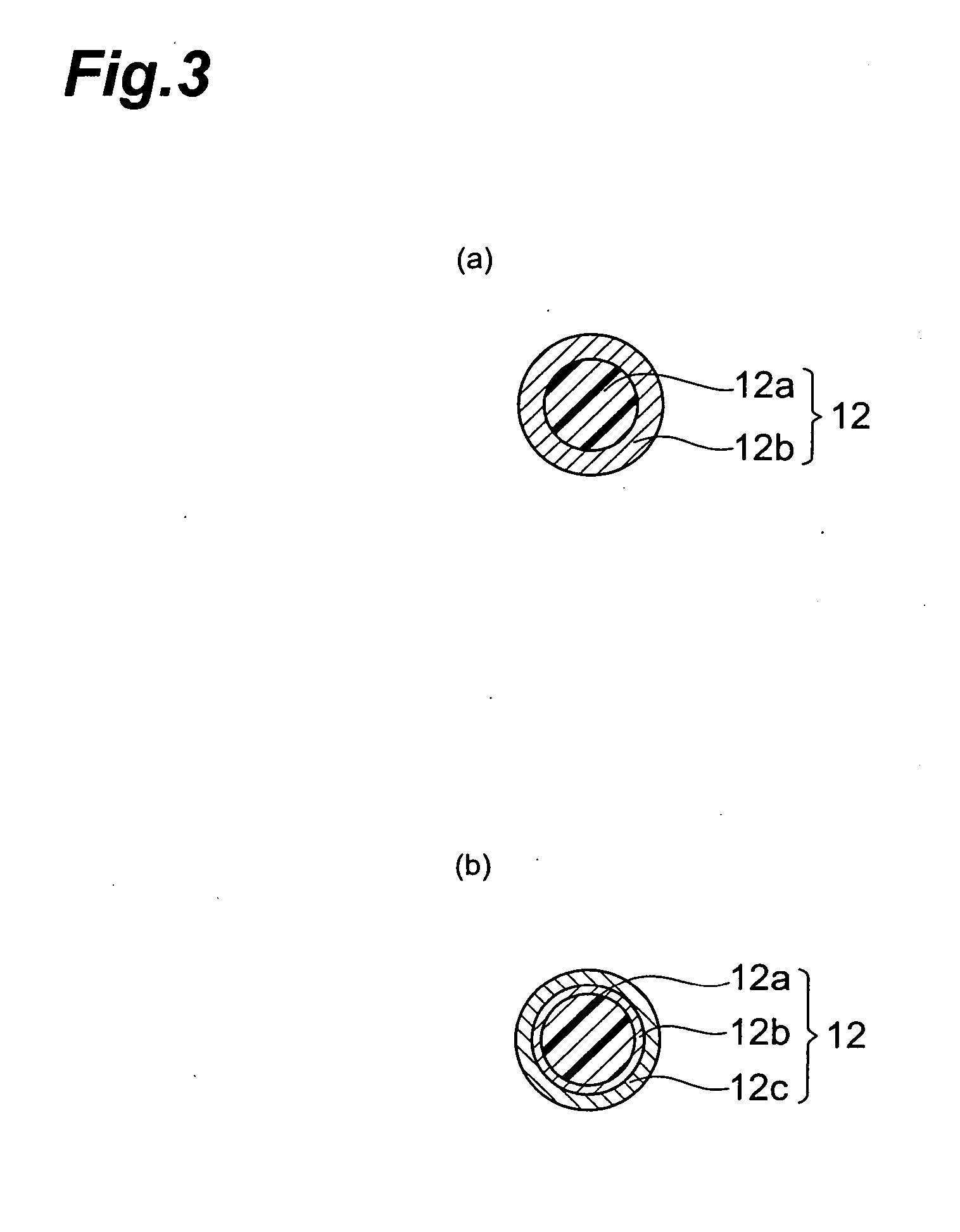

[0114] 50 g of a phenoxy resin (commercial name: PKHC, manufactured by Union Carbide K.K., average molecular weight 45,000) was dissolved in a mixed solvent of toluene / ethyl acetate (=50 / 50 in terms of weight ratio), thus producing a solution with a solid content of 40 wt %.

[0115] Next, 30 g of a phenoxy resin, 30 g of a bisphenol A type epoxy resin and 40 g of Novacure (commercial name 3941HPS, manufactured by Asahi-Ciba K.K.) used as a latent curing agent for the epoxy resin (all amounts here are given in terms of solid content weight ratio) were added to the abovementioned solution. Furthermore, 5 volume parts of conductive particles No. 1 were further added and dispersed in this solution per 100 volume parts of the bonding agent composition, thus preparing a liquid containing a circuit connecting material. Furthermore, the Novacure 3941HPS of the abovementioned latent curing agent is a master batch type curing agent in which a micro-encapsulated curing agent with a mean particl...

example 2

[0117] The film-form circuit connecting material of Example 2 was obtained in the same manner as in Example 1, except for the fact that conductive particles 2 were used instead of the conductive particles 1 used in Example 1.

example 3

[0118] The film-form circuit connecting material of Example 3 was obtained in the same manner as in Example 1, except for the fact that conductive particles 3 were used instead of the conductive particles 1 used in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com