Fuel cell and cell fastening pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

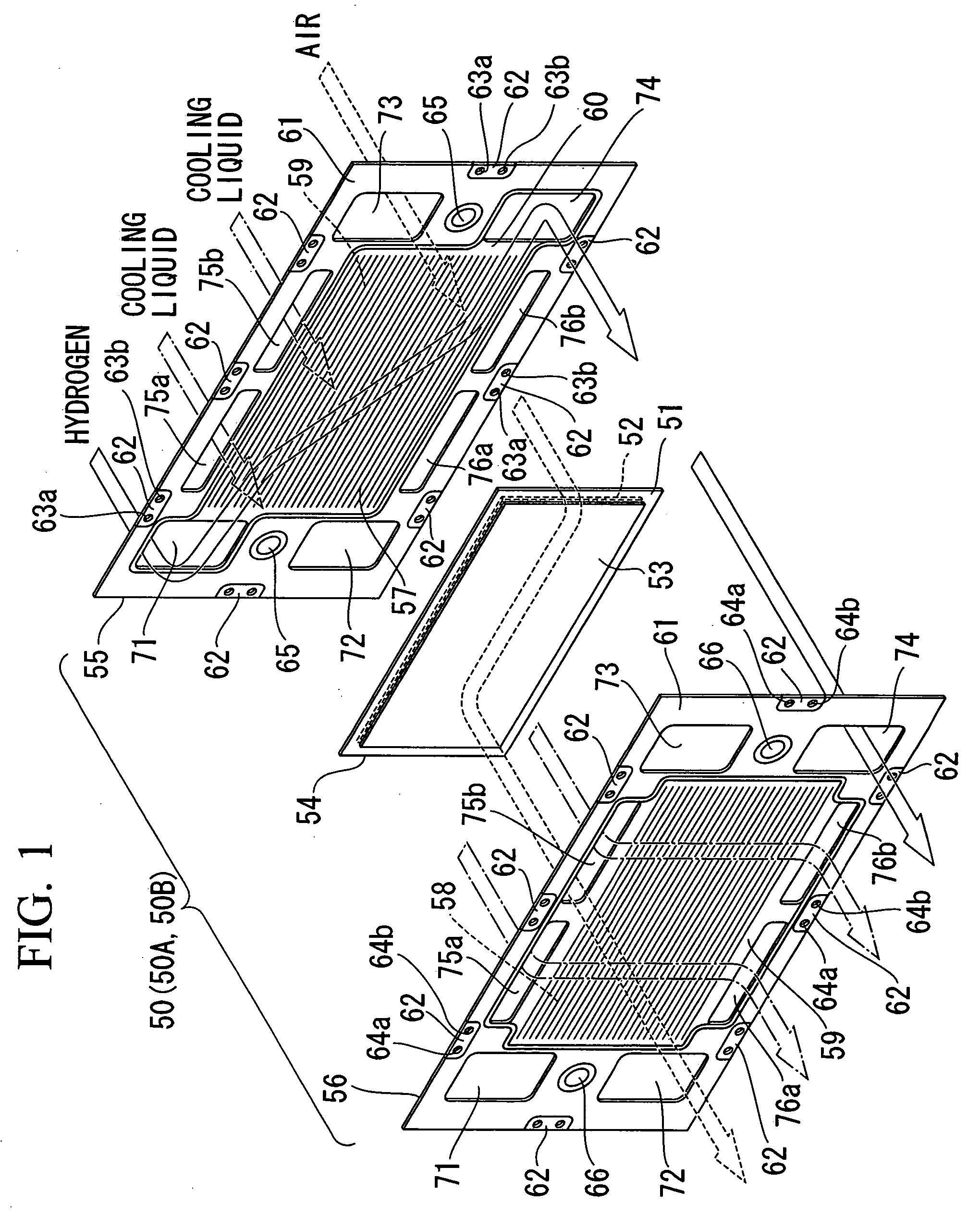

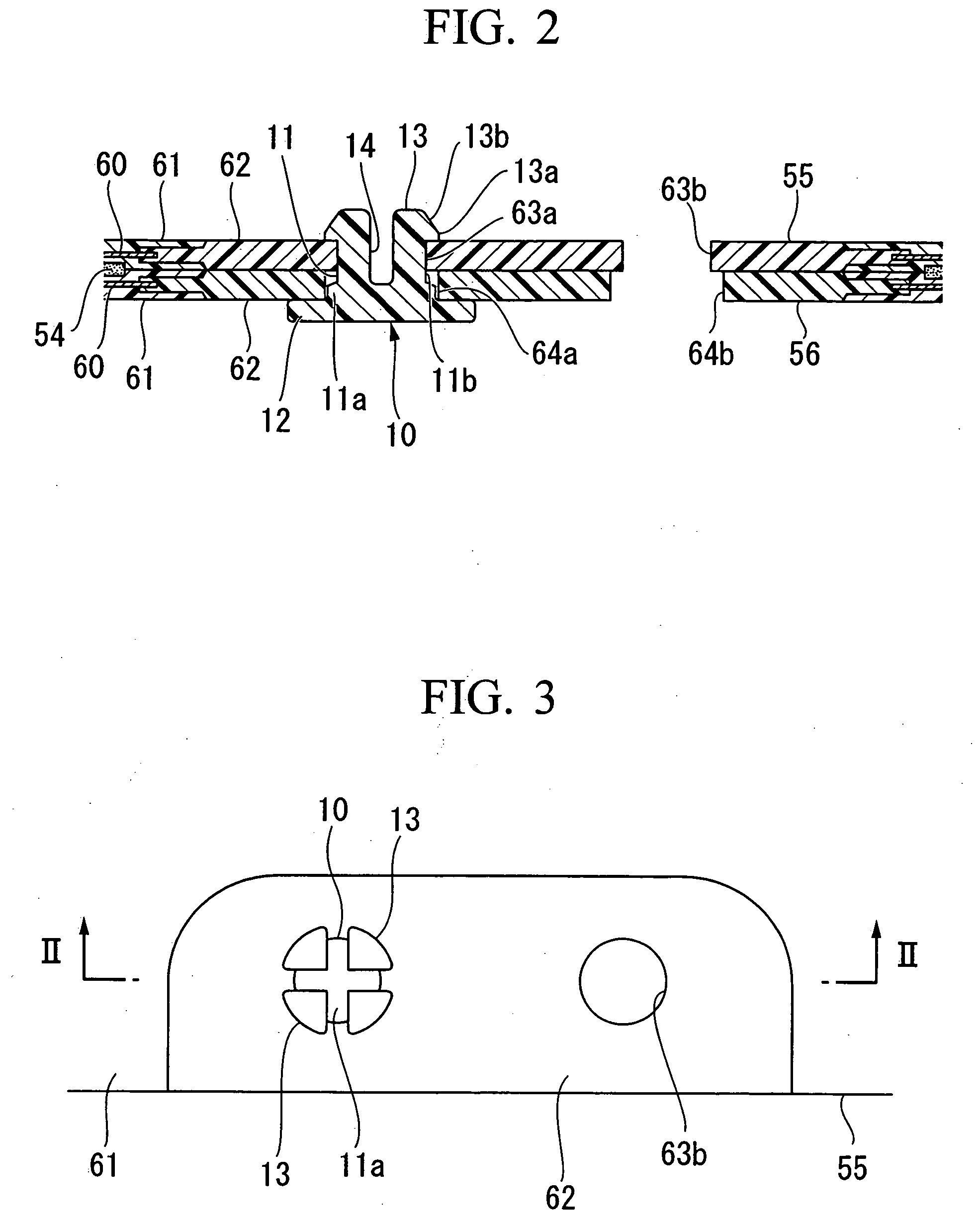

[0048] Hereinafter, embodiments of a fuel cell and a cell fastening pin according to the present invention will be described with reference to the appended figures (i.e., FIGS. 1 to 10).

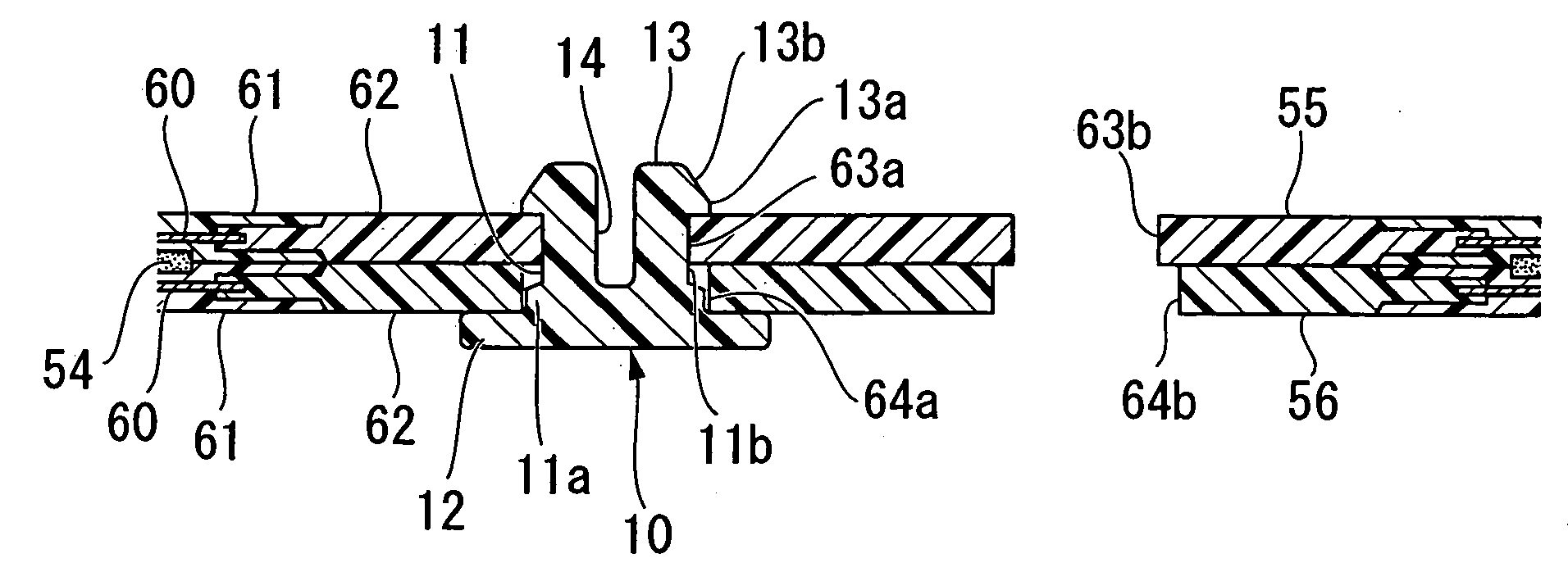

[0049]FIG. 1 is an exploded perspective view showing a unit cell of the fuel cell as an embodiment of the present invention. The fuel cell in the present embodiment is a solid polymer electrolyte membrane type. As shown in FIG. 1, an anode 52 (i.e., an electrode) and a cathode 53 (i.e., another electrode) are provided on either side of a solid polymer electrolyte membrane 51 (made of a fluorine electrolyte material or the like) so as to form a membrane electrode assembly 54. The membrane electrode assembly 54 is closely placed between an anode separator 55 (corresponding to a second separator in the present invention) and a cathode separator 56 (corresponding to a first separator in the present invention) so as to form a unit cell 50 (i.e., a unit fuel cell). A plurality of the unit cells 50 are sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com