Lithographic apparatus and method for determining Z position errors/variations and substrate table flatness

a technology of z position errors and z-position variations, applied in the direction of broaching tools, printing, instruments, etc., can solve the problems of small range, high equipment cost, and inability to accurately measure the flatness of the substrate,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

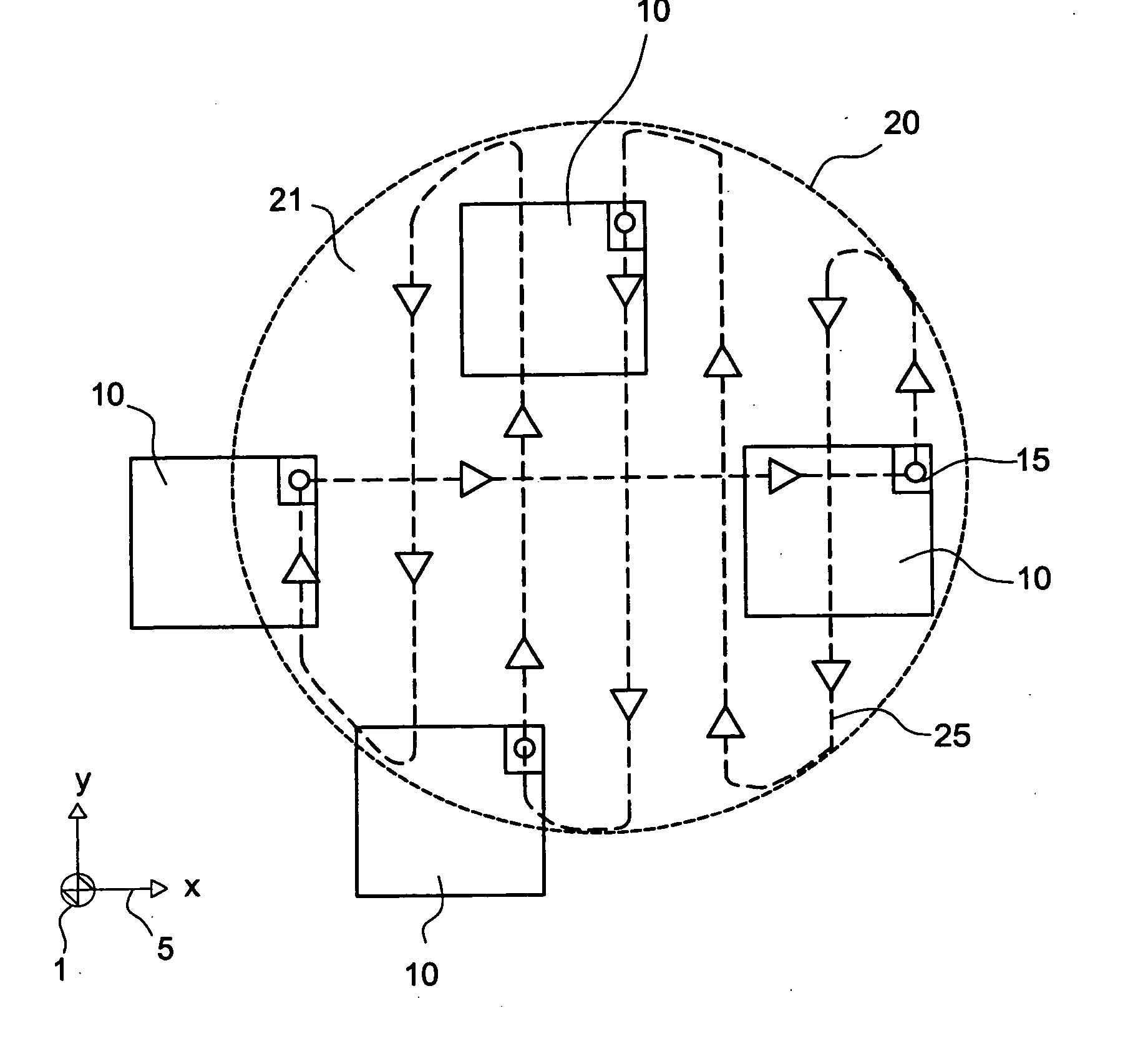

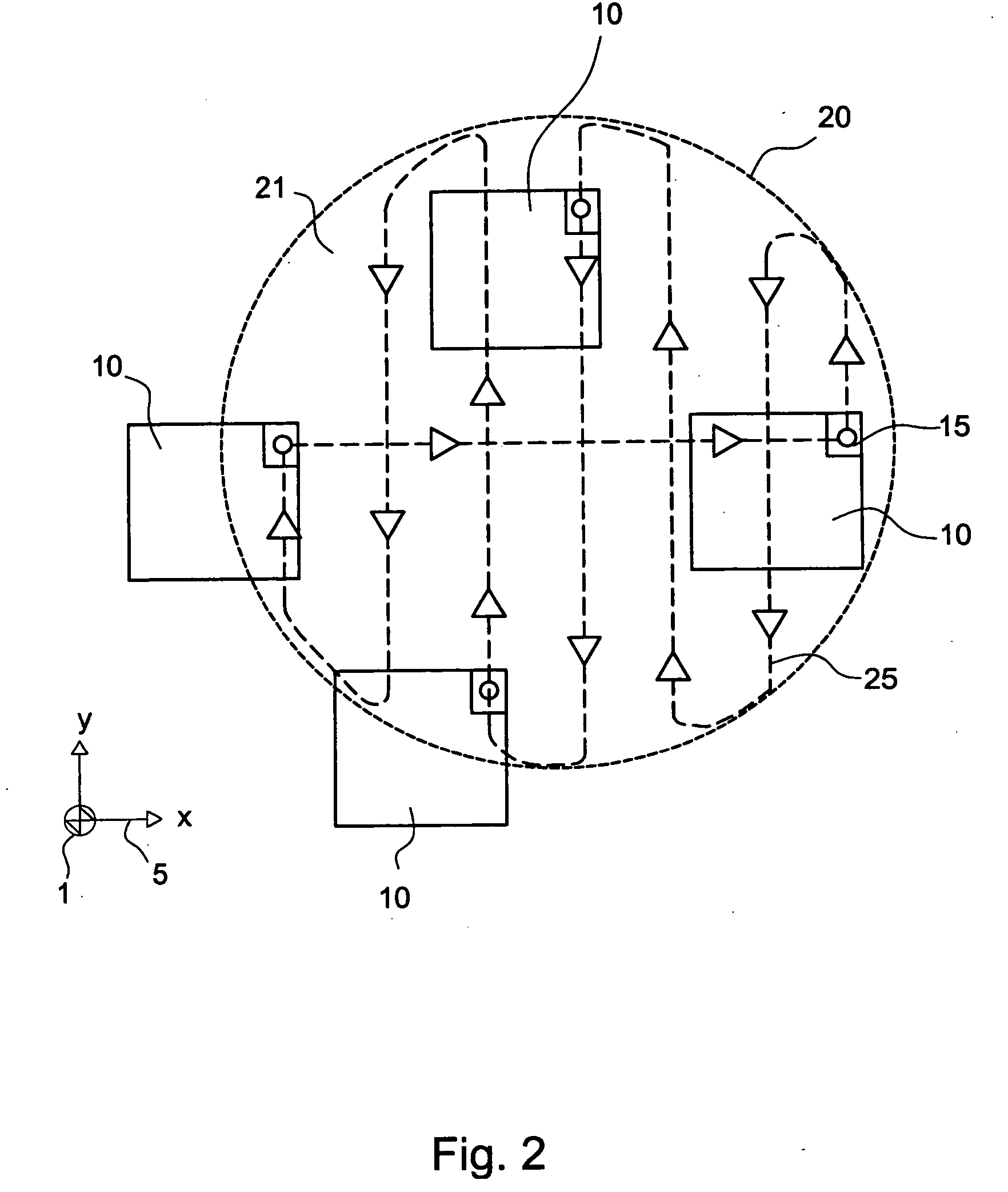

[0068]FIG. 2 schematically illustrates the first embodiment of the present invention. In FIG. 2, a base 1 is shown, relative to which moveable object 10 moves in the x-y-plane that is indicated by coordinate system 5. The x-y plane is also indicated as the “plane of movement”. The moveable object 10 follows a track in the x-y-plane. FIG. 2 illustrates this by showing the position of the moveable object 10 at four positions along the track.

[0069] The moveable object 10 comprises a reference part 15, which moves along with the moveable object 10. The track the reference part 15 of the moveable object 10 follows in the plane of movement is indicated by reference numeral 25. All movements of the reference part 15 are within area 21 of the plane of movement. Area 21 is bound by a closed contour 20.

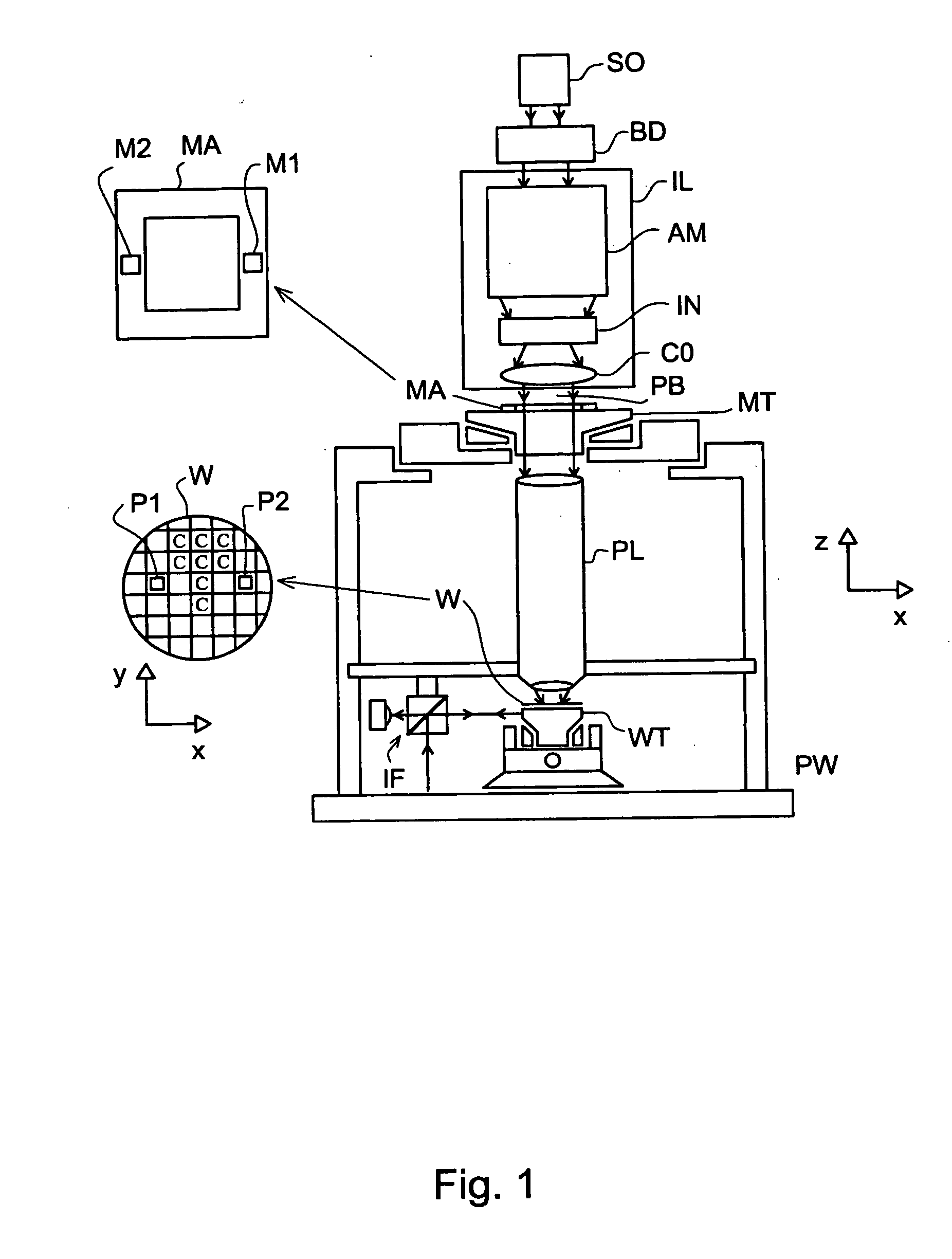

[0070]FIG. 3 schematically depicts a part of a lithographic apparatus associated with the first embodiment of the invention. In this case, moveable object 10 is a substrate table or holder 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com