Swaging-optimized baseplate for disk drive head suspension

a technology for suspensions and disk drives, applied in the direction of support for heads, record information storage, instruments, etc., can solve the problems of affecting the operation performance of the suspension, and being observed to be particularly prevalent, so as to achieve the effect of reducing the deformation of the actuator arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

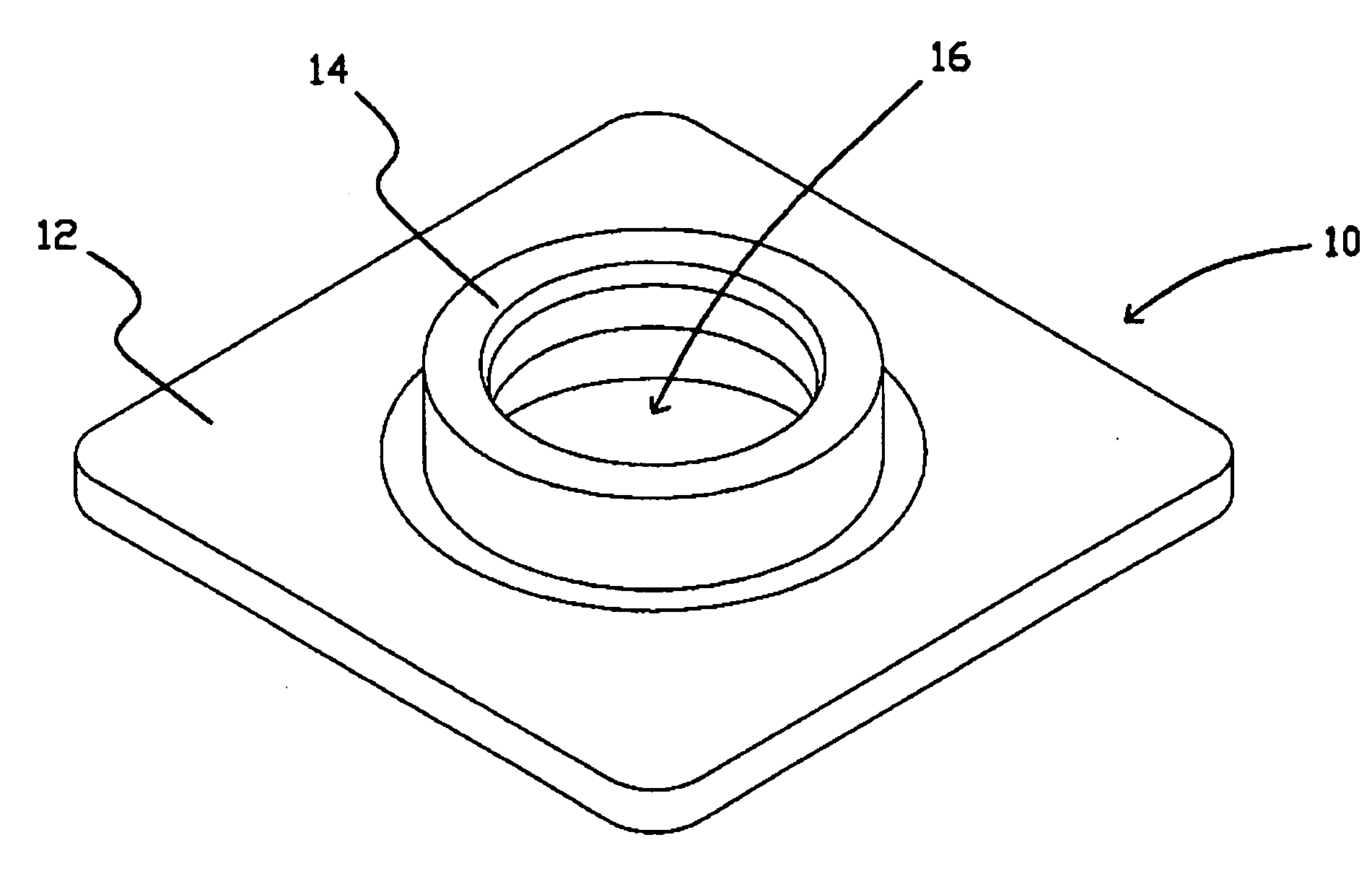

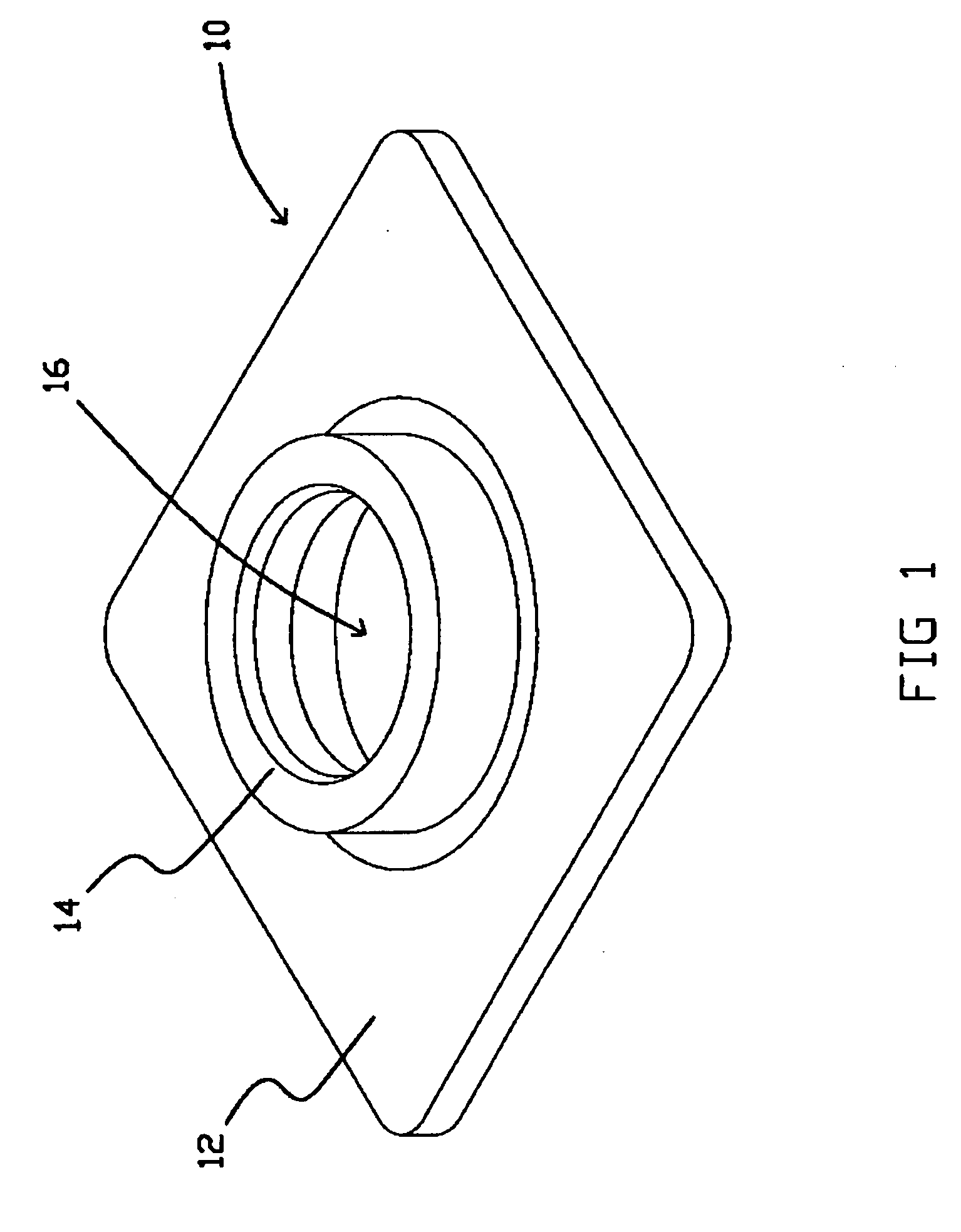

[0011]FIG. 1 is an illustration of a baseplate 10 that can be configured in accordance with the present invention to produce relatively little or minimal swaging-induced deformation in an actuator arm to which it is swaged. As shown, baseplate 10 includes a generally flat flange 12 and a tubular boss tower 14 that extends from the flange and surrounds a swaging hole 16. Baseplates such as 10 are typically manufactured from stainless steel by stamping processes, although other materials and manufacturing methods can also be used.

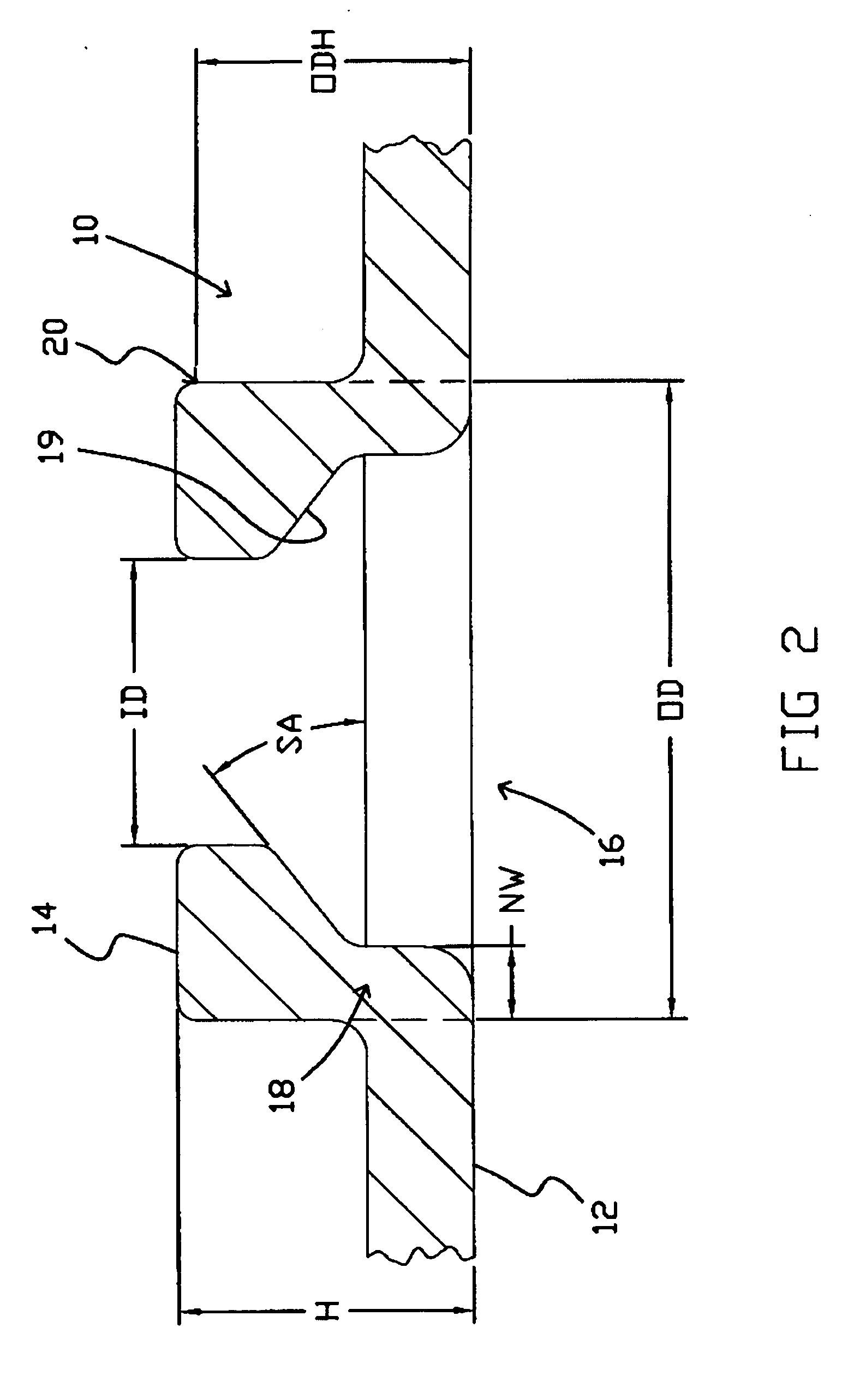

[0012]FIG. 2 is a cross sectional illustration of the baseplate 10 with the boss tower 14 shown in greater detail. As shown, the tower 14 includes a neck 18 and generally increases in cross sectional dimension (into the hole 16) with increasing distance from the flange 12. The tower 14 has a width NW at the neck 18. The cross sectional dimension of the tower increases at a stamping angle SA. In the illustrated embodiment the angled surface. 19 of the tower 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| OD | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com