Thermosyphon device, cooling and heating device and method using the thermosyphone device, and plant cultivating method

a technology of thermosyphon and wick, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, and stationary conduit assemblies, etc., can solve the problems of difficult to maintain a state in which these wicks are difficult to be easily produced, and the major construction work must be performed for a change in the tube arrangement, etc., to achieve the effect of simple structure, low cost and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

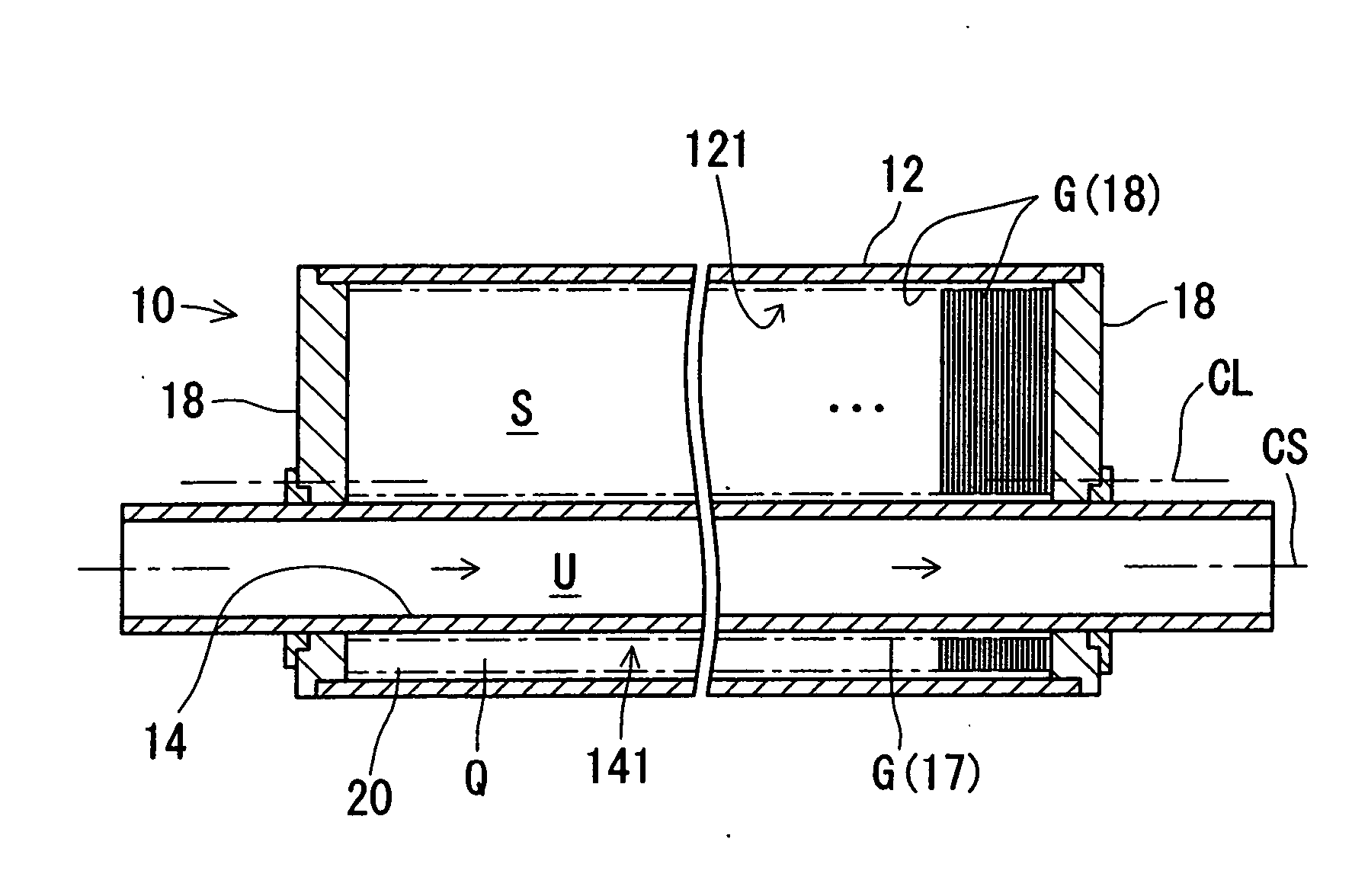

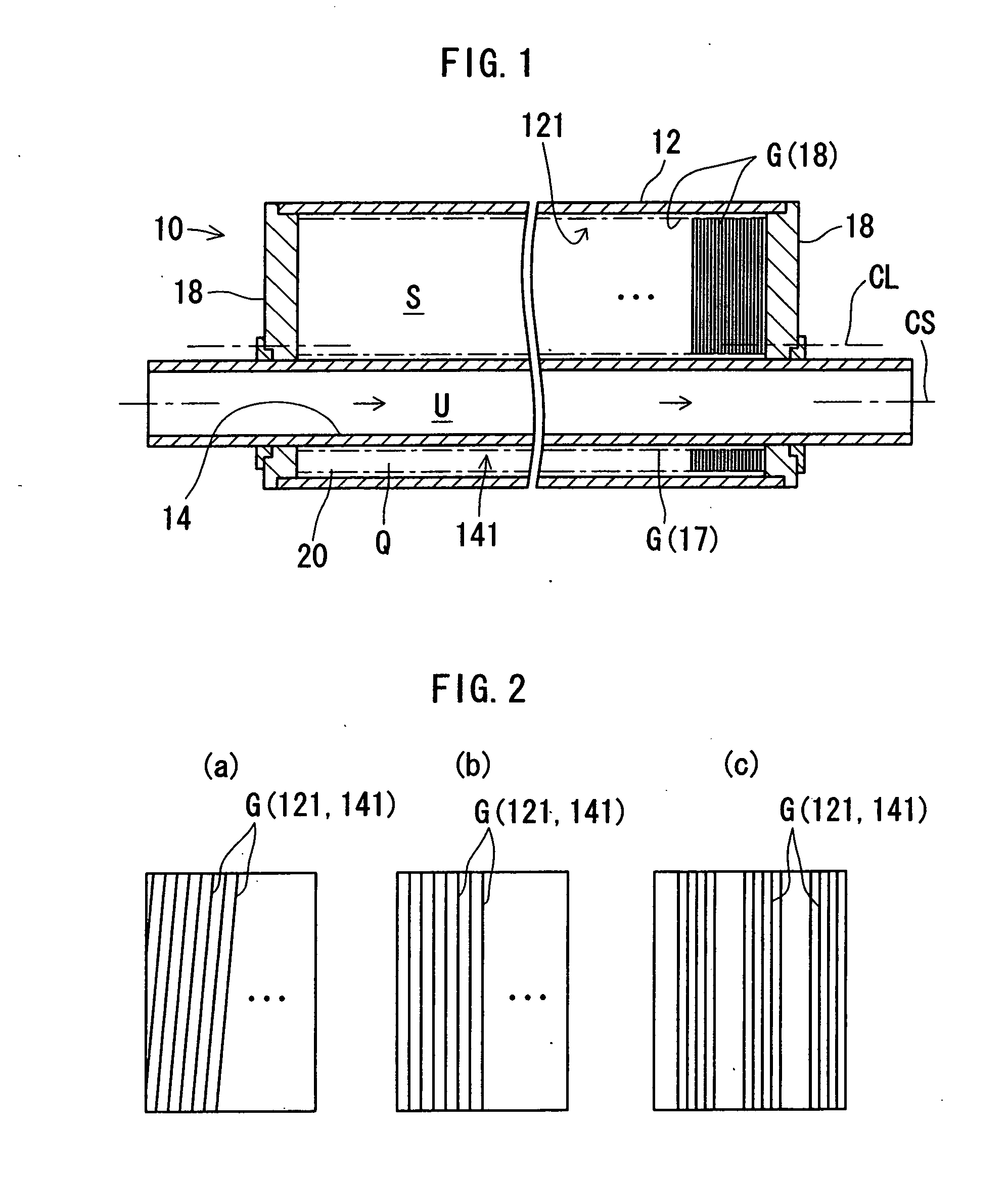

Method used

Image

Examples

examples 1 and 2

Design Examples 1 and 2

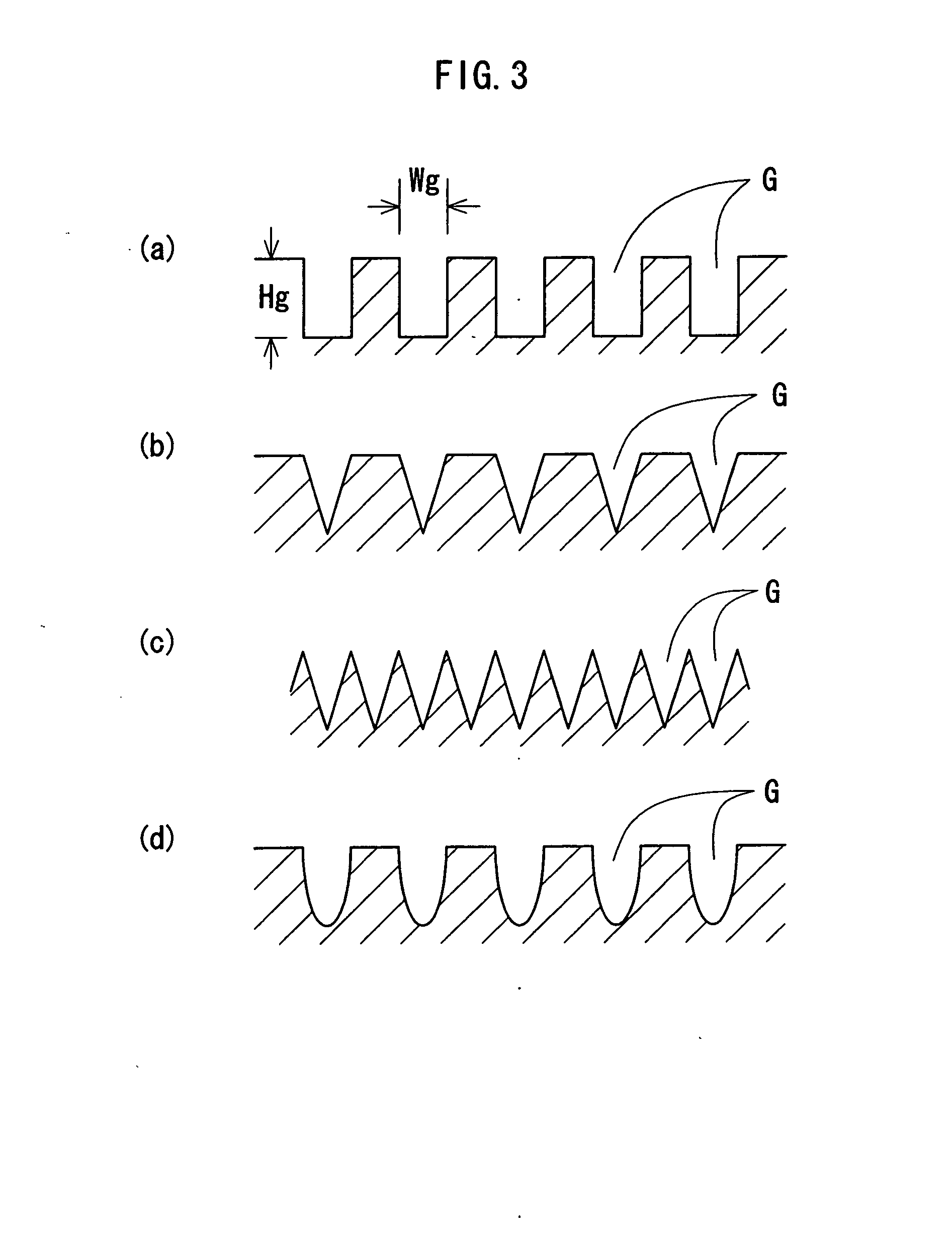

[0055] When the surroundings of the device are cooled at the maximum heat transportation amount during cooling (cold water is used as a fluid flowing through the inner tube), the outer tube serves as an evaporating portion, and the inner tube serves as a condensing portion. Therefore, it is recommended to calculate the maximum heat transportation amount by the capillary pressure limit of the outer tube group as the maximum heat absorption amount. Accordingly, calculated values Qmax / L (W / m) of the maximum heat transfer amount per unit length during cooling when ethanol and water are each used as an operating fluid are shown in Table 1 concerning Design Example 1 and Table 2 concerning Design Example 2. In the calculation, the operating temperature (steam temperature) Tv was 10° C. In the tables, Qmax / L(W / m) is the maximum heat transfer amount per unit length, Wg is the width of the outer tube grooves (narrow concave grooves), Hmax is the maximum capillary heigh...

examples 3 and 4

Design Examples 3 and 4

[0057] When the surroundings of the device are heated at the maximum heat transportation amount during heating (warm water is used as a fluid flowing through the inner tube), the outer tube serves as a condensing portion, and the inner tube serves as an evaporating portion. Therefore, it is recommended to calculate the maximum heat transportation amount by the capillary pressure limit of the inner tube grooves as the maximum heat radiation amount. Accordingly, calculated values Qmax / L(W / m) of the maximum heat transfer amount per unit length during heating when ethanol and water are each used as an operating fluid are shown in Table 3 and Table 4. In the calculation, the operating temperature (steam temperature) Tv was 40° C.

TABLE 3Table 3 Maximum heat transfer amount of inner tube grooves duringheating (operating fluid: ethanol)WgHmaxSgHg [mm]Ng[mm][mm][mm]0.20.30.4[number / m]0.413.40.5—15550011111.0—1003217141.5—732375262.0—581874170.317.90.5101623144912501....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com