Method of decorating laminated glass

a technology of laminated glass and decoration method, which is applied in the direction of coatings, instruments, transportation and packaging, etc., can solve the problems of warping or shape distortion, the application of decoration methods that cannot employ screen-printing, etc., and achieves the effect of superior clarity and adequate strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

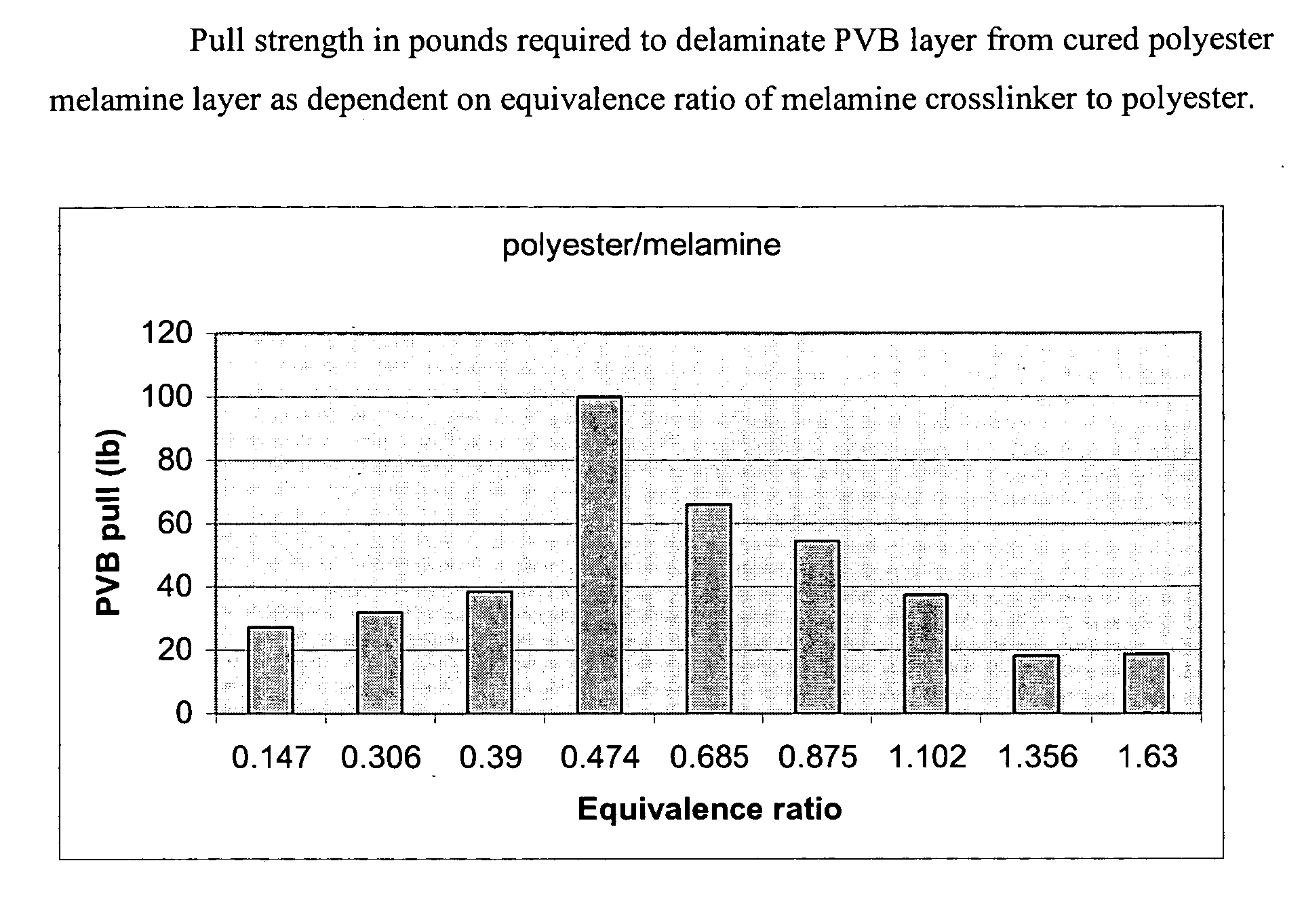

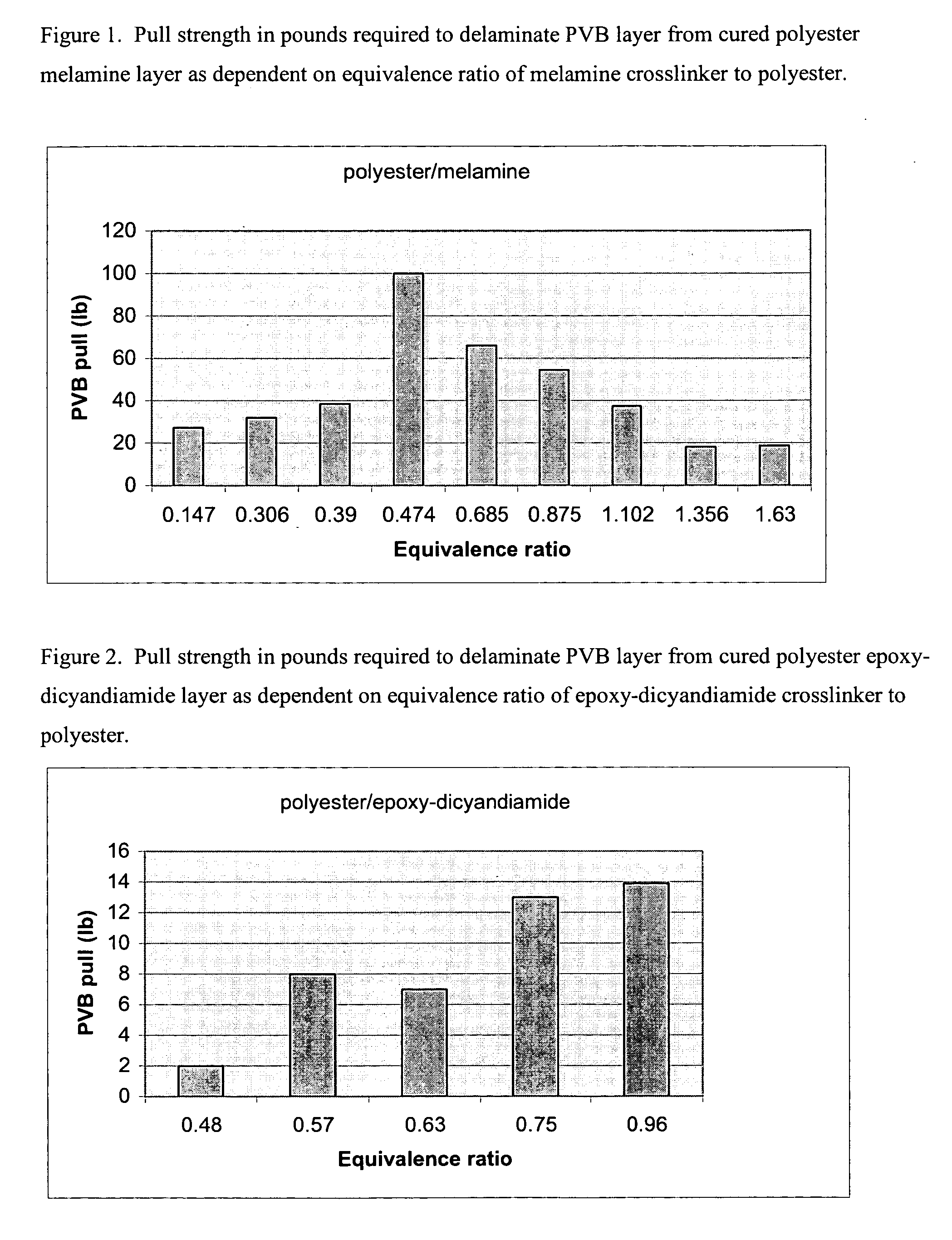

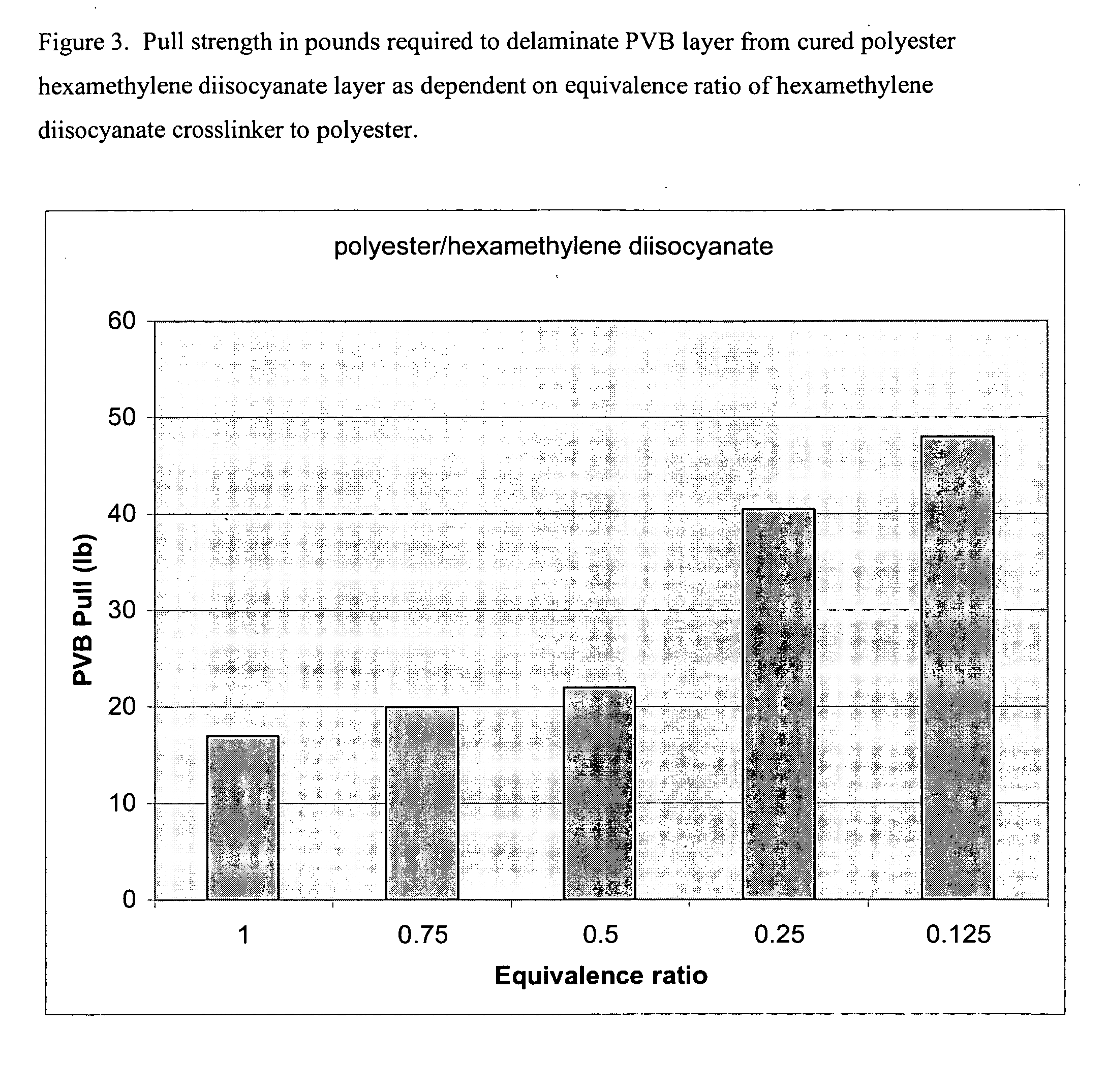

Image

Examples

Embodiment Construction

[0013] The method of forming a decorated glass structure involves a pigment package composition, which comprises a crosslinkable thermoset resin, a crosslinker and a pigment. However, the composition typically further comprises solvents, catalysts, surfactants, light stabilizers, UV blockers, and adhesion promoters. Each ingredient is discussed in turn.

[0014] Thermoset Resin. Broadly, the green pigment package composition, prior to curing, comprises about 50 to about 95% thermoset resin, preferably about 55 to about 90%, more preferably about 60 to about 75% and most preferably about 60 to about 65%. All percentages herein are by weight. The thermoset resin may be any thermoplastic polymer having crosslinkable functional sites. Suitable types of thermoset resins include polyesters, urethanes, vinyl polymers, acrylics, styrenes, aromatic polyolefins, aliphatic polyolefins, polycarbonates, copolymers thereof, and blends thereof. The preferred thermoset resins are polyesters. Polyeste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com