Modular vinyl fence system

a fence system and modular technology, applied in fencing, building types, constructions, etc., can solve the problems of inconvenient installation and maintenance of wooden fence systems, inconvenient assembly, and low overall cost of installing and maintaining wooden fence systems, so as to eliminate the need for tools, reduce installation and maintenance costs, and ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

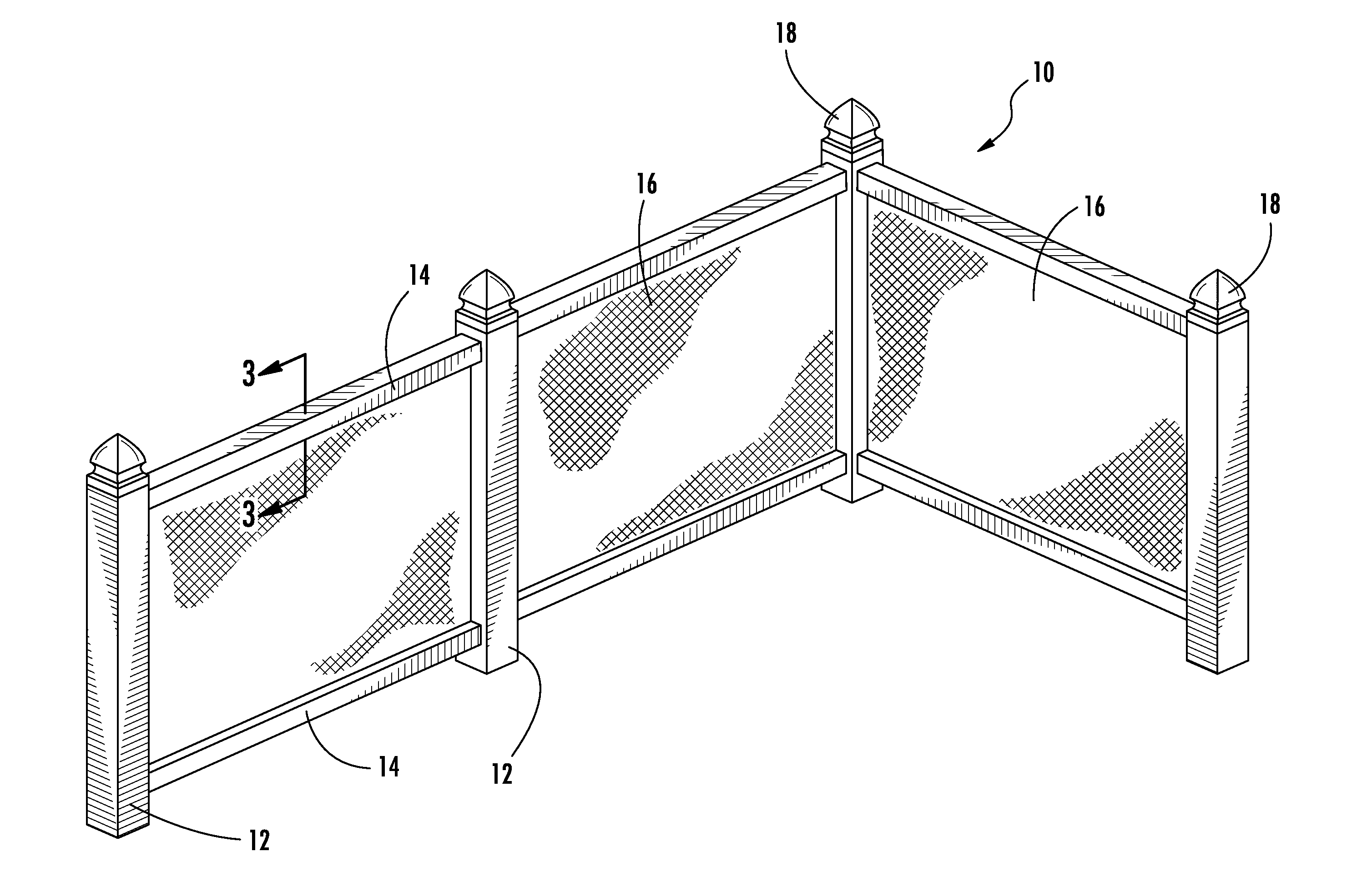

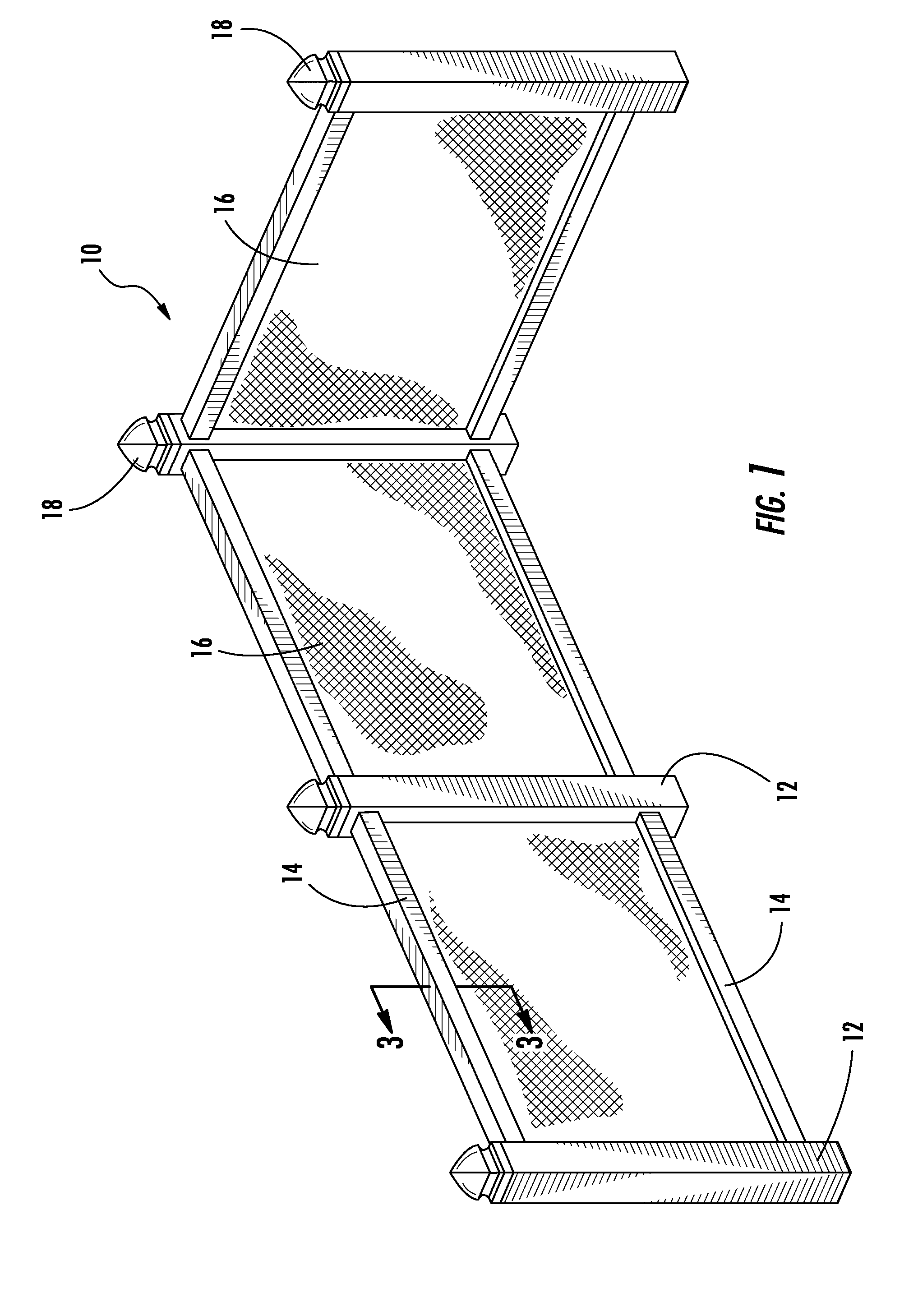

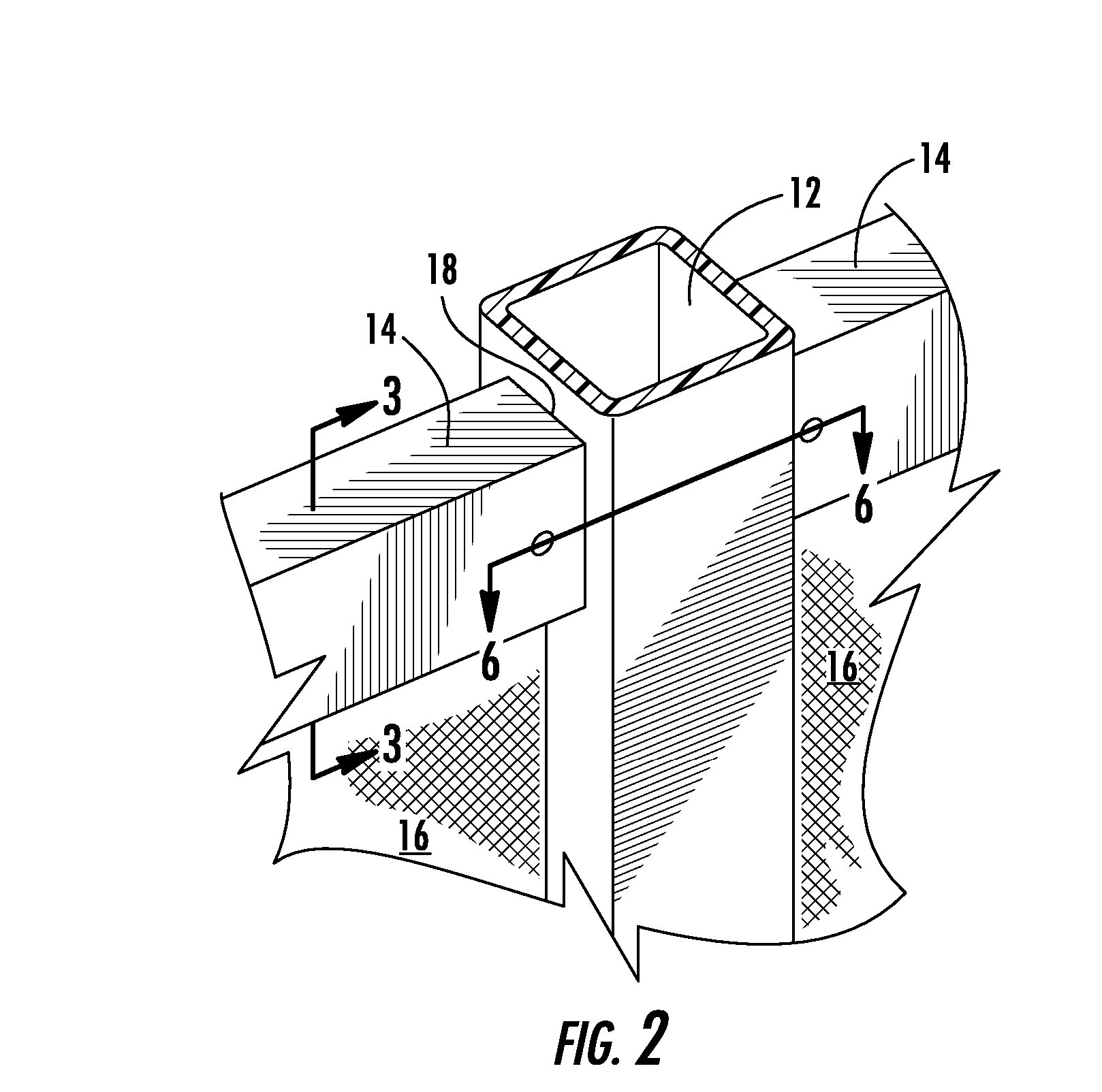

[0027] Referring now to the drawings, the fencing system of the present invention is illustrated and generally indicated at 10 in FIGS. 1-6. Further, an alternate embodiment of the present invention is illustrated and generally indicated at 100 in FIG. 7. In addition, various other components such as an alternate rail connector, hinge, latch and corner connector are depicted in FIGS. 8-11. As will hereinafter be more fully described, the fencing system 10 is assembled in sections wherein each section includes at least two vertical support posts 12 with at least two horizontal rails 14 extending therebetween. Each section of the fence system 10 may also include a fencing panel 16 supported between the horizontal rails 14 and caps 18 installed onto the vertical supports 12. The present invention therefore provides a convenient and economical modular fencing system 10 that is easily assembled and installed making the system convenient for both permanent and temporary fence installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com