Vacuum breaker

a vacuum breaker and breaker technology, applied in mechanical equipment, transportation and packaging, valve types, etc., can solve problems such as inaccuracy of response and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

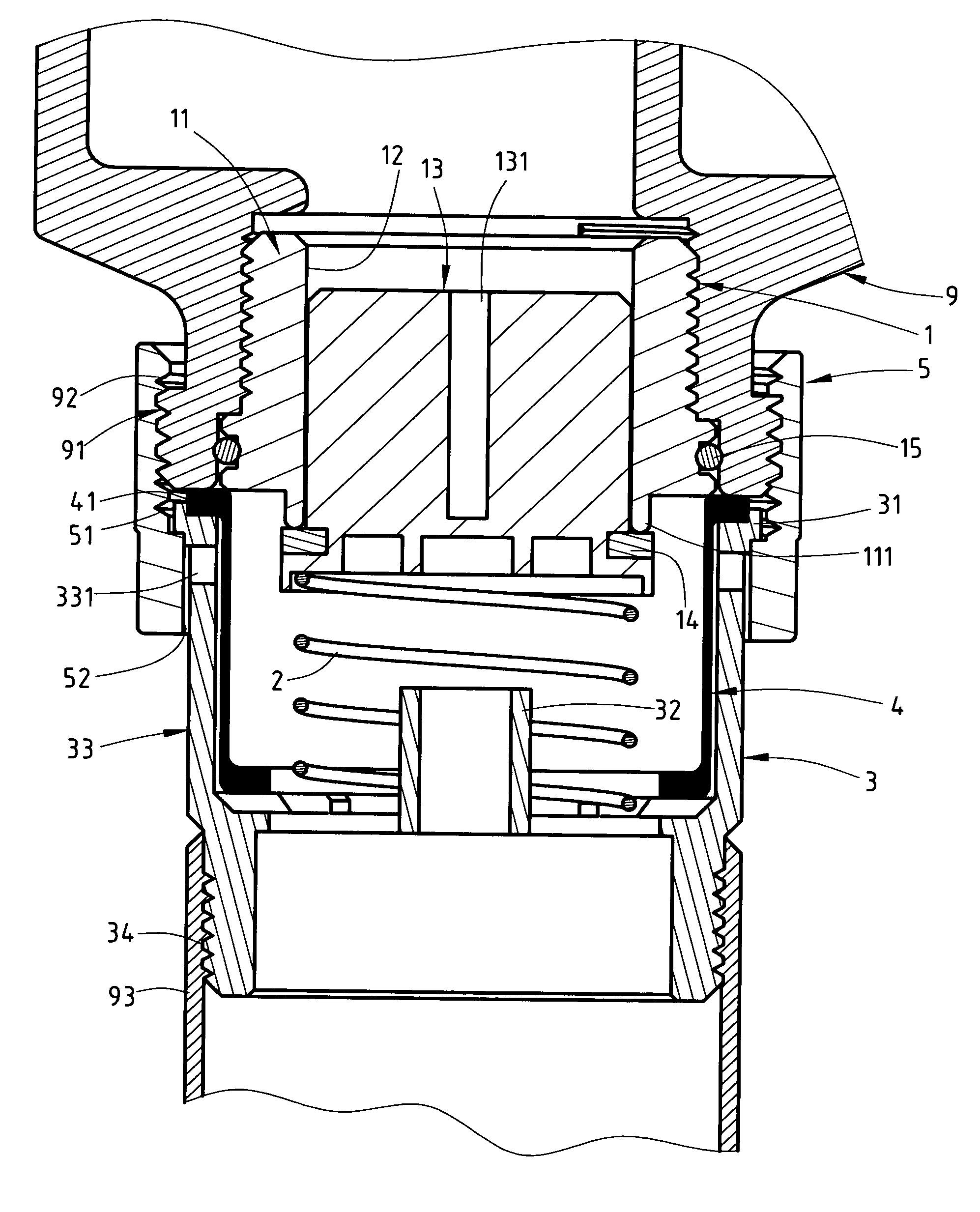

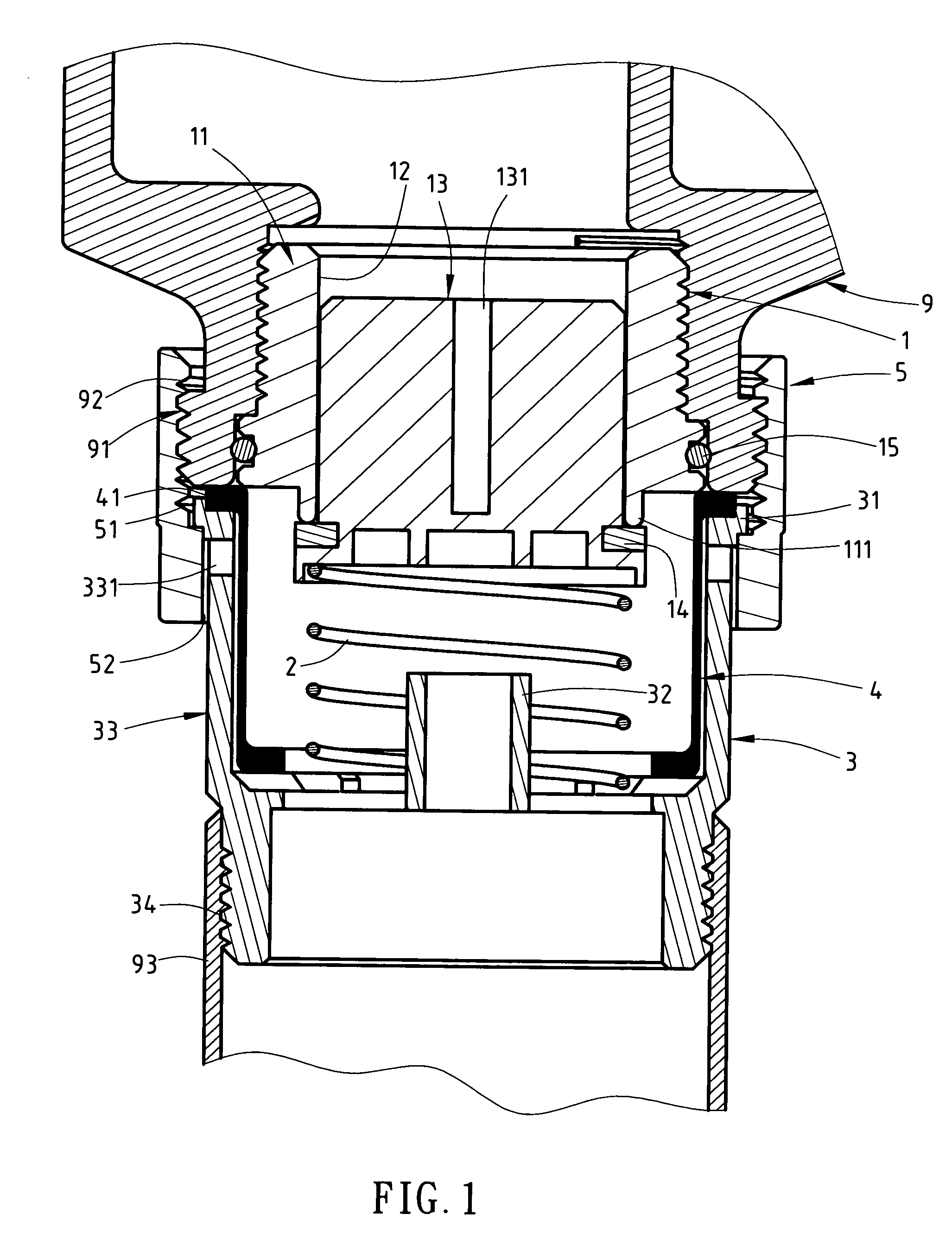

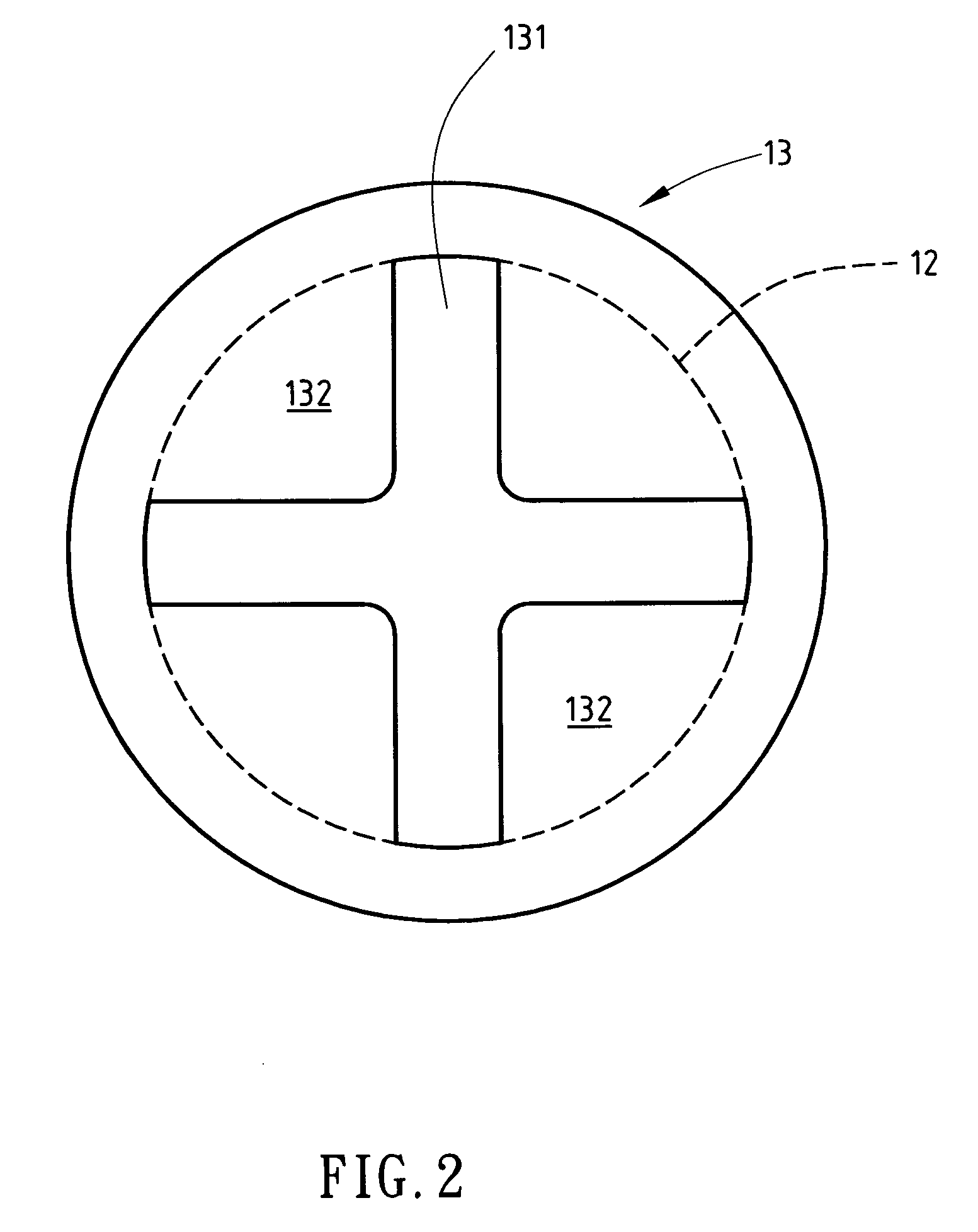

[0015] Refer to FIGS. 1 and 2 for an embodiment of the vacuum breaker of the invention. It is installed on a water discharge end 91 of a flush valve 9. It includes a valve 1, a spring 2, a coupling duct 3, a bushing 4 and a nut 5. The valve 1 has a valve seat 11 screwing in the water discharge end 91 of the flush valve 9. The bottom of the valve seat is coupled with an O-ring 15. The valve seat 11 has a hollow section 12 to house a plug 13 which is movable up and down. The plug 13 has a bottom coupled with a retaining ring 14 which seals a bottom end 111 of the valve seat 11 when flushing is stopped. The plug 13, referring to FIG. 2, has a cross rib 131 on a upper side forming a plurality of water inlets 132 corresponding to the hollow section 12 of the valve seat 11 so that water flushing from the flush valve 9 passes through the plug and is divided into several water streams to become a more stable water flow. The spring 2 has one end pressing the bottom of the plug 13 and other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com