Automatic cleaning device

a cleaning device and automatic technology, applied in the direction of carpet cleaners, electric equipment installation, applications, etc., can solve the problems of unintentional separation of dirt receptacles from the installation chamber, no function of sensing, and contamination of the room, so as to increase the air tightness of the connecting region, simplify the structure, and increase the coupling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

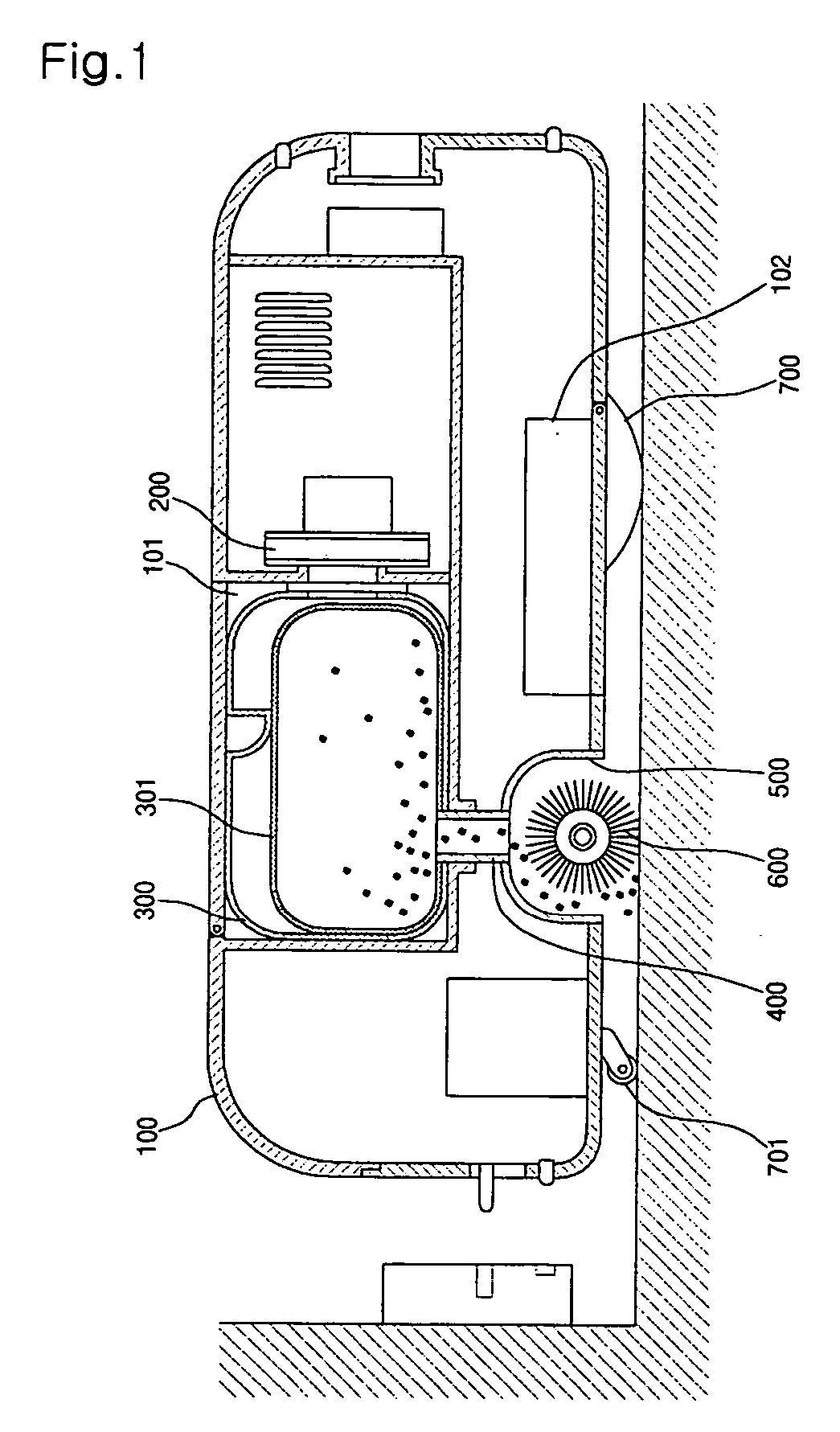

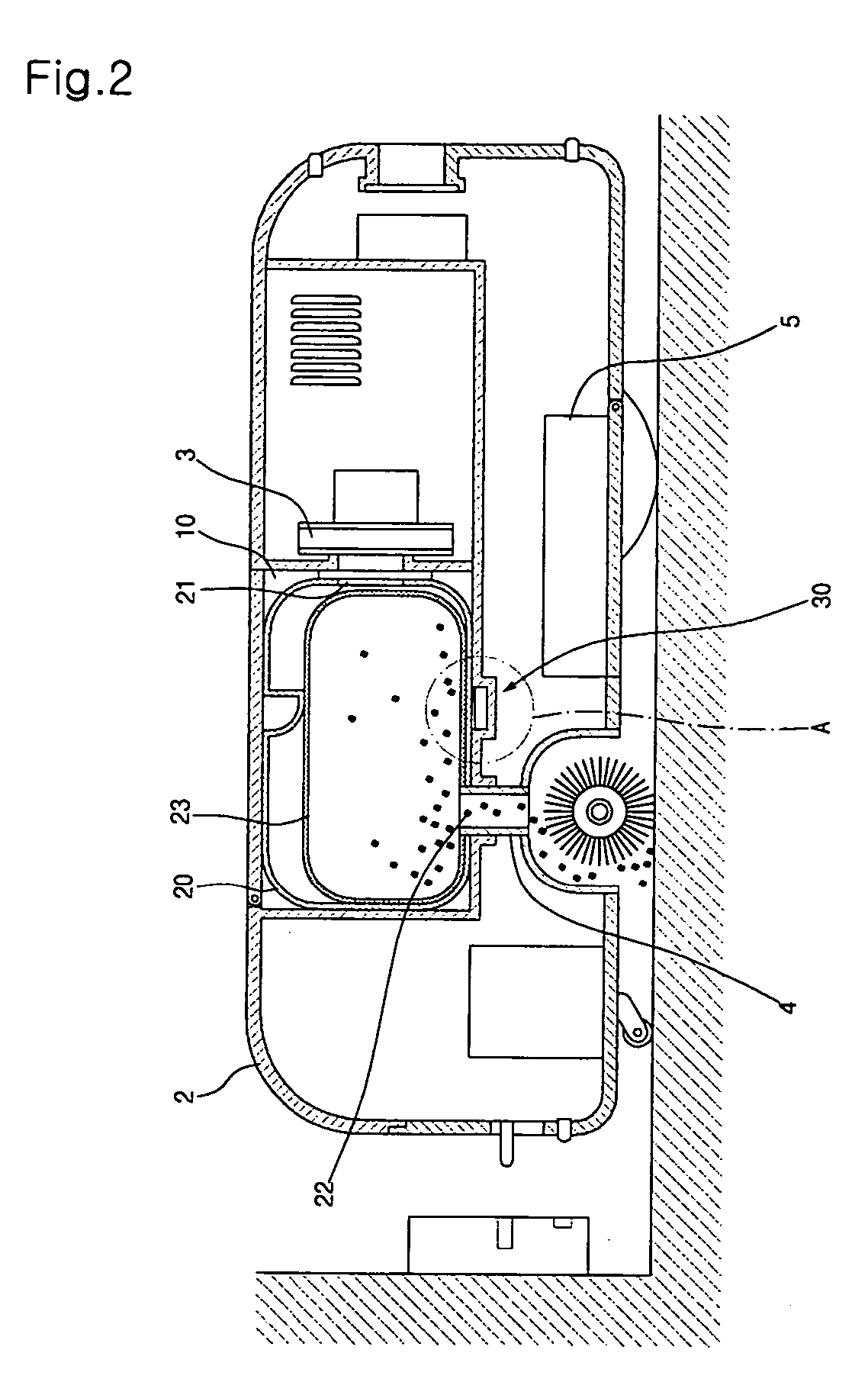

[0050]FIG. 2 is a schematic longitudinal sectional view illustrating an automatic cleaning device in accordance with the present invention. FIG. 3 is an enlarged sectional view of circle A of FIG. 2. FIG. 4 is an enlarged section view illustrating separation of a dirt receptacle of FIG. 3.

[0051] As shown in FIGS. 2 to 4, the automatic cleaning device according to the first embodiment of the present invention comprises: a body 2; a fan motor 3 to generate a suction force; an installation chamber 10 defined in the body 2; a dirt receptacle 20 detachably mounted in the installation chamber 10; and a dirt receptacle sensor unit 30 to sense the presence of the dirt receptacle 20.

[0052] The installation chamber 10 is defined in the body 2 at a position connected with the fan motor 3. Thus, the dirt receptacle 20, which is mounted in the installation chamber 10, is connected with the fan motor 3.

[0053] The dirt receptacle 20 has a through-hole 21, so that the dirt receptacle 20 is connec...

second embodiment

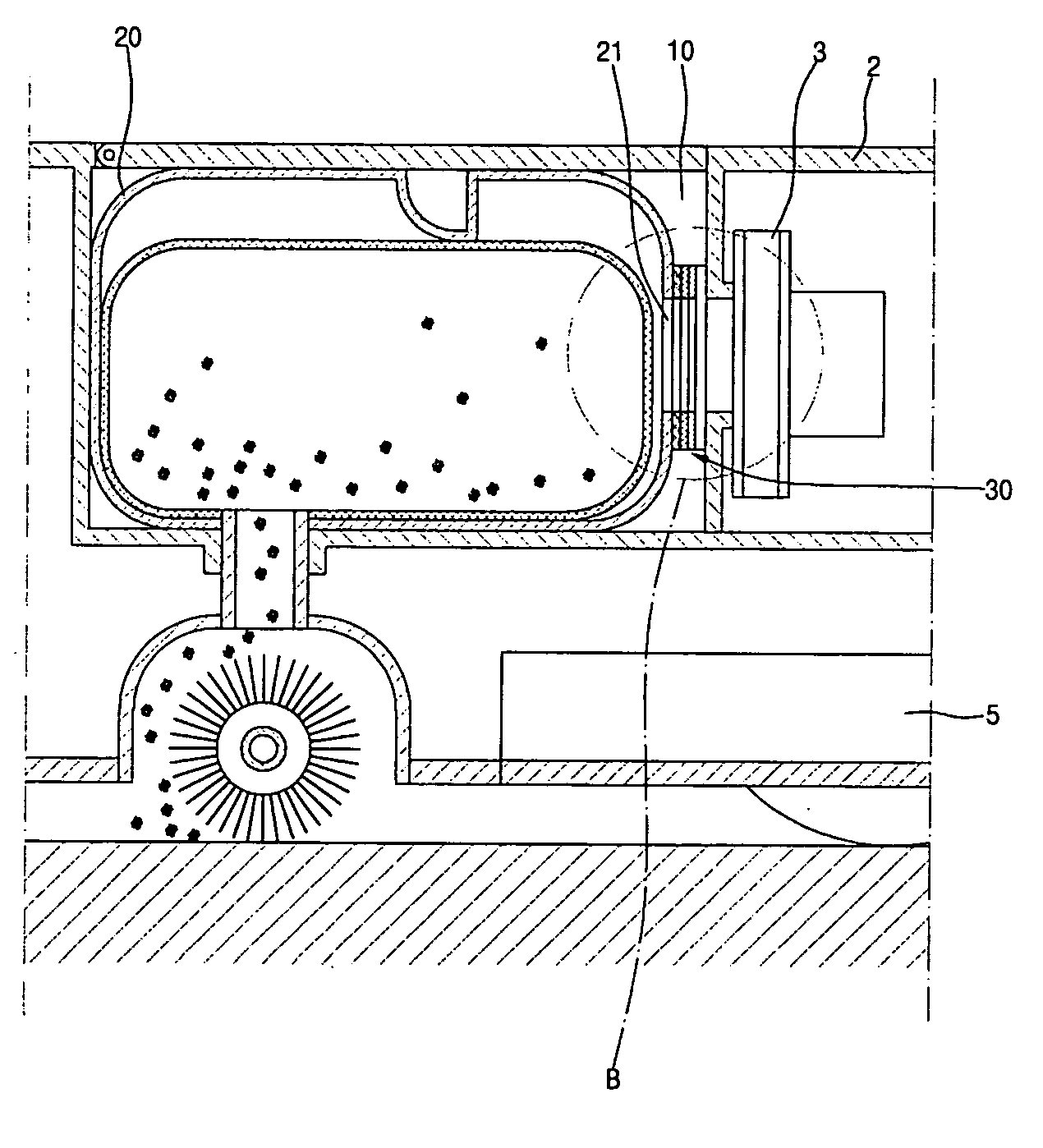

[0061]FIG. 5 is a schematic longitudinal sectional view illustrating an automatic cleaning device in accordance with the present invention. FIG. 6 is an enlarged sectional view of circle B of FIG. 5. FIG. 7 is an enlarged section view illustrating separation of a dirt receptacle of FIG. 6.

[0062] As shown in FIGS. 5 to 7, the automatic cleaning device according to the second embodiment of the present invention comprises: the body 2; the fan motor 3; the installation chamber 10 defined in the body 2 to be connected with the fan motor 3; the dirt receptacle 20 detachably mounted in the installation chamber 10; and the dirt receptacle sensor unit 30 to sense the presence of the dirt receptacle 20.

[0063] The dirt receptacle sensor unit 30 is mounted in the installation chamber 10 so that it senses the absence of the dirt receptacle 20 inside the installation chamber 10 and inputs the sensed result into the controller 5. The dirt receptacle sensor unit 30 of the present embodiment includ...

third embodiment

[0068]FIG. 8 is a schematic longitudinal sectional view illustrating an automatic cleaning device in accordance with the present invention. FIG. 9 is an enlarged sectional view of circle C of FIG. 8. FIG. 10 is an enlarged section view illustrating separation of a dirt receptacle of FIG. 9.

[0069] As shown in FIGS. 8 to 10, the automatic cleaning device according to the third embodiment of the present invention comprises: the body 2; the fan motor 3; the installation chamber 10 defined in the body 2 to be connected with the fan motor 3; the dirt receptacle 20 detachably mounted in the installation chamber 10; and the dirt receptacle sensor unit 30 to sense the presence of the dirt receptacle 20.

[0070] The dirt receptacle sensor unit 30 is mounted in the installation chamber 10 so that it senses the absence of the dirt receptacle 20 inside the installation chamber 10 and inputs the sensed result into the controller 5. The dirt receptacle sensor unit 30 of the present embodiment inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com