Production of polyhydroxyalkanoate in plants

a technology of polyhydroxyalkanoate and plant, applied in the field of plant genetic manipulation, can solve the problems of slow degradation of synthetic plastics in landfills, and high cost of polymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Engineering Plants to Produce PHA Copolymers

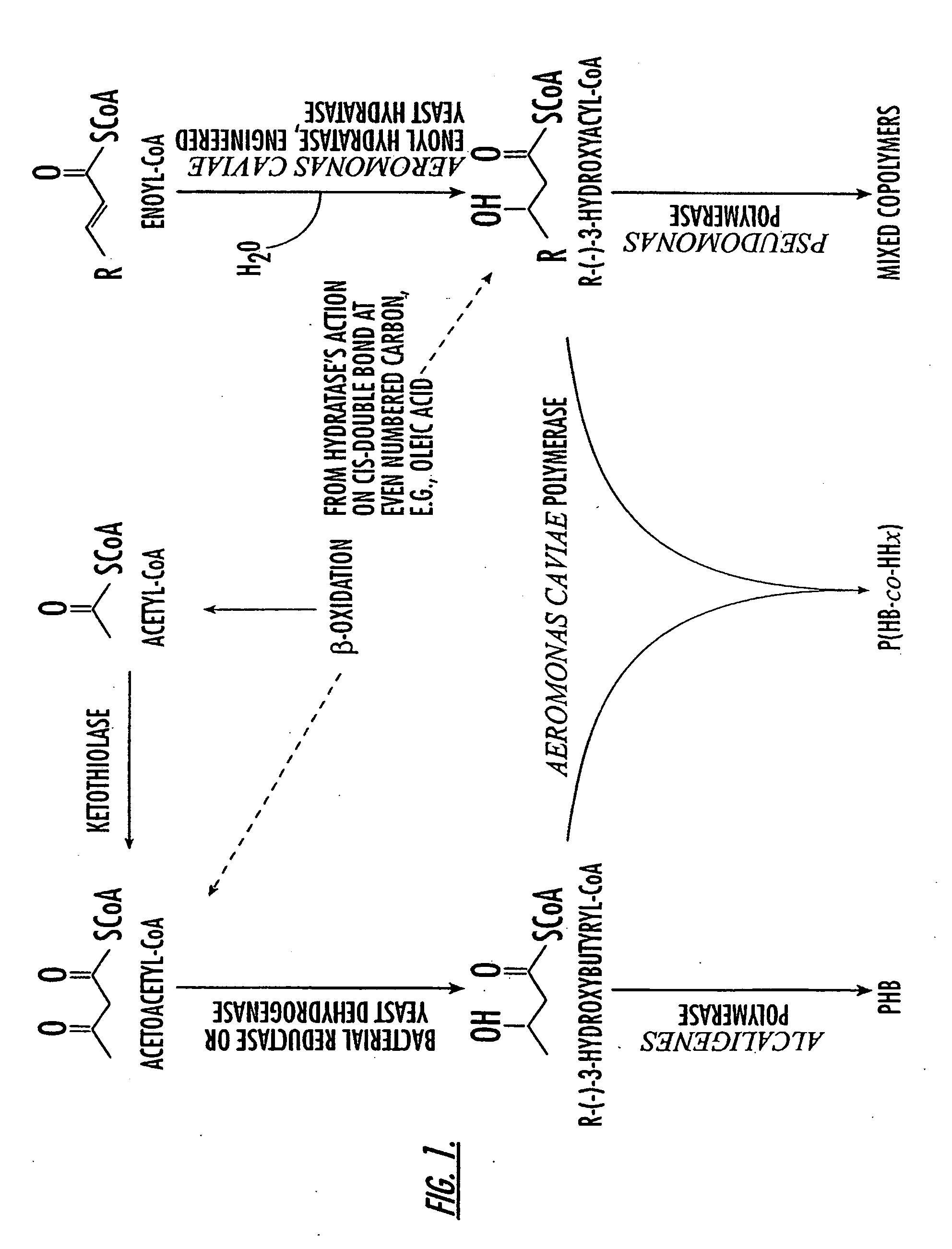

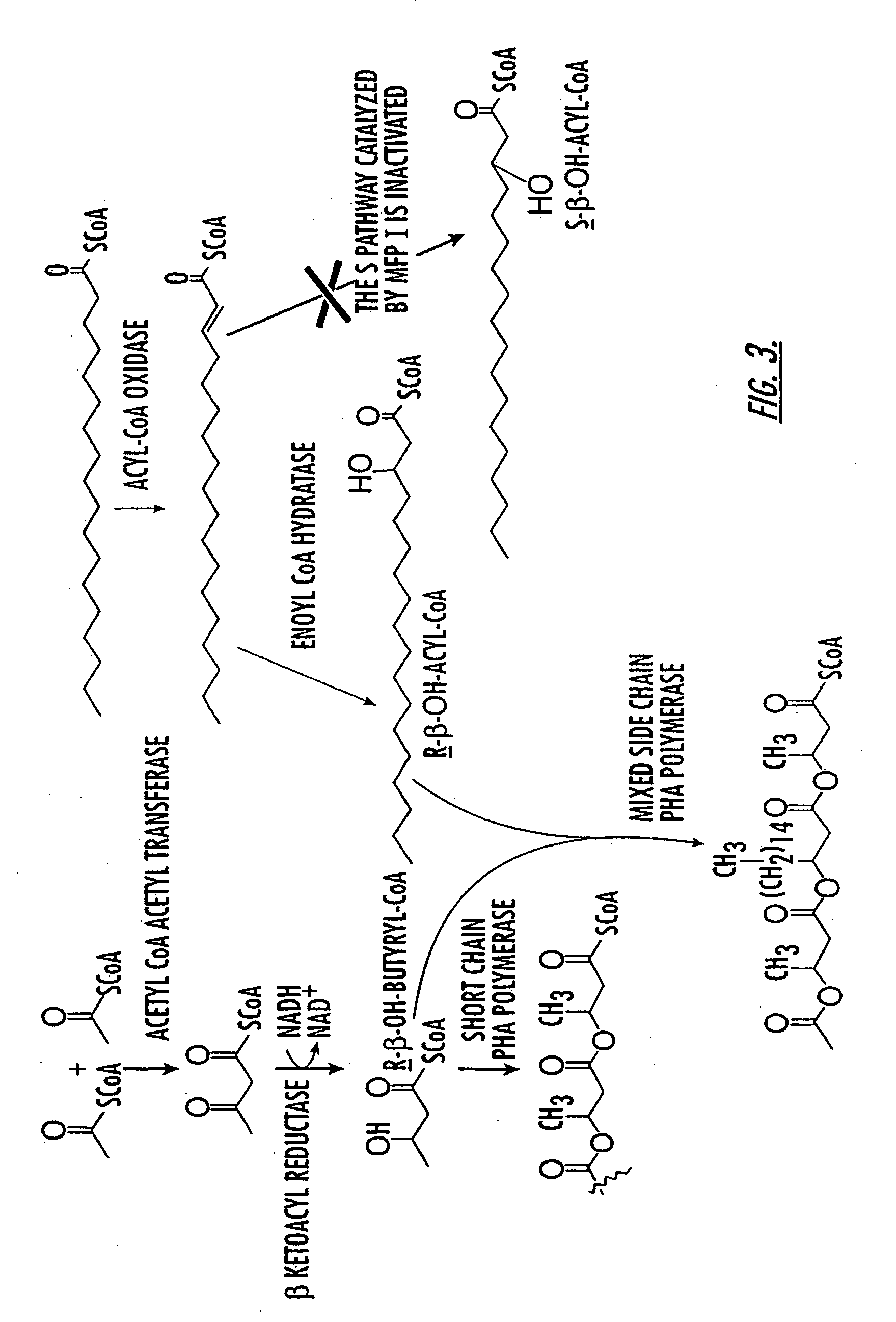

[0120] Bacteria can produce PHA copolymers because these substrates are apparently derived from the β-oxidation cycle; as bacterial cells are uncompartmented, both β-oxidation and PHA synthesis take place in the cytosol. In plants, however, β-oxidation is confined primarily to peroxisomes and thus offers a suitable site for copolymer production. Using methods known to those of ordinary skill in the art, signal sequences for targeting proteins to peroxisomes can be added to PHA-producing enzymes, allowing the localization of these enzymes in the peroxisomes. Such signal sequences for targeting proteins to plant peroxisomes are well known (Mullen et al. (1997) Plant Journal 12:313-322; Trelease et al. (1 996) Protoplasma 195:156-167).

[0121] An intermediate in β-oxidation is S-(+)-3-hydroxyacyl-CoA. However, its configuration is unsuitable for PHA synthases, which require R-(−)-3-hydroxyacyl-CoA as a substrate (Gemgross et al. (1995) Proc. ...

example 2

Production of Specific Types of PHA in Plants

[0126] It is desirable to produce a pure copolymer of a defined monomer composition. A relatively pure copolymer would have predictable properties in comparison to a mixture of copolymers as the composition of the latter can vary according to the environment. The ability of Pseudomonas sp. to make copolymers of PHAs from various substrates is well known to those skilled in the art. However, the PHA synthases from these species have a broad substrate range (Caballero et al. (1995) Int. J. Biol. Macromol. 17:86-92; Huisman et al. (1989) Appl. Environ. Microbiol. 55:1949-1954; Lee et al. (1995) Appl. Environ. Microbiol. 42:901-909; Ramsay et al. (1990) Appl. Environ. Microbiol. 56:2093-2098; Steinbuechel et al. (1992) Appl. Environ. Microbiol. 37:691-697;Timm et al. (1992) Eur. J. Biochem. 209:1R-30). When a genomic fragment containing the PHA synthase gene from Thiocapsa pfennigii (see, WO 96 / 08566) was introduced into Pseudomonas putida o...

example 3

Engineering a Peroxisomal 2-Enoyl-CoA Hydratase from a Yeast Multifunctional Protein

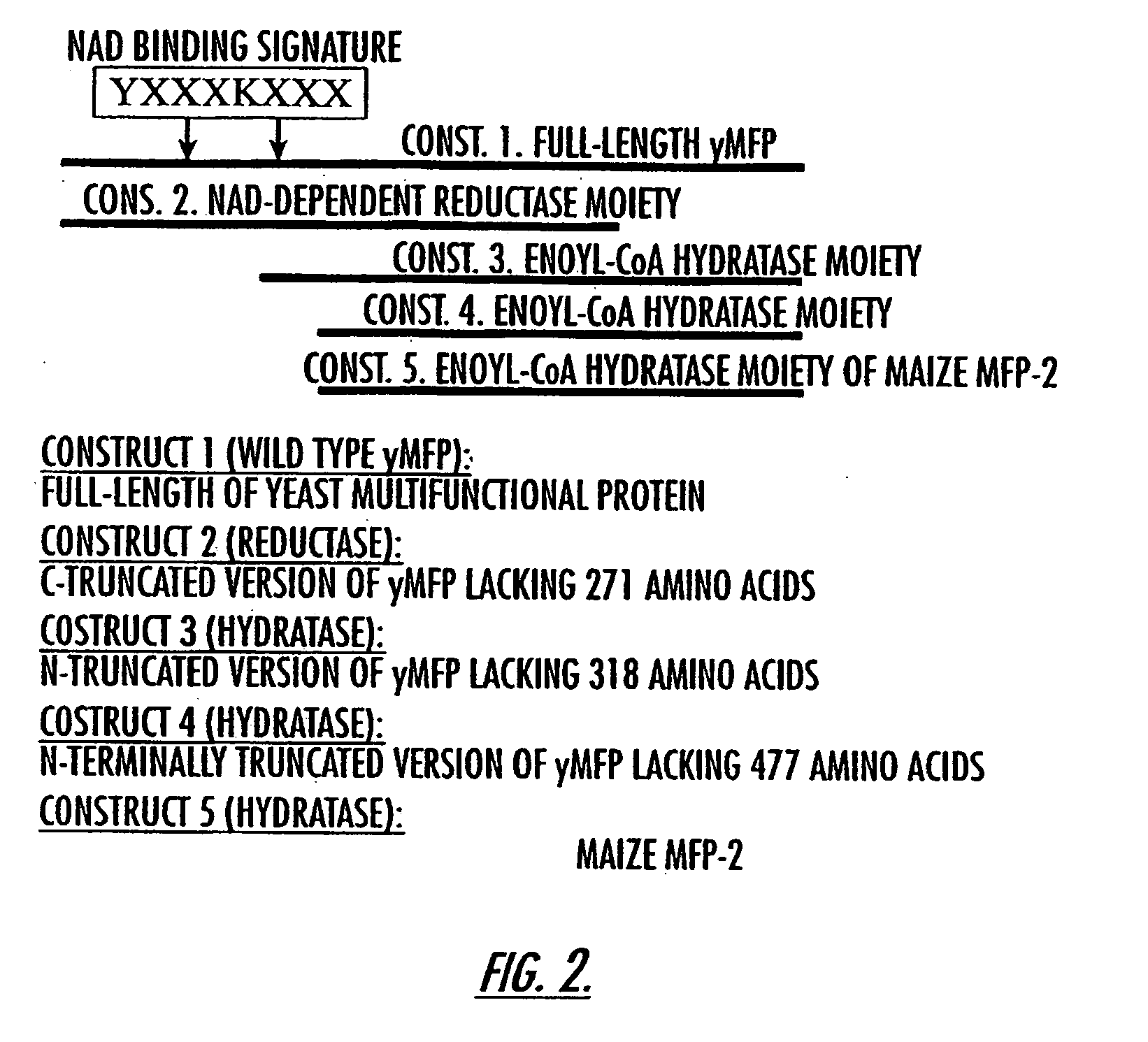

[0131] To produce PHA in plant peroxisomes, it is essential to effectively divert 2-enoyl-CoA from β-oxidation and to the synthesis of R-(−)-3-hydroxyacyl-CoA, the substrate of PHA synthase. In contrast to the multifunctional protein in other organisms, yeast multifunctional protein (encoded by GenBank Accession No. M86456, SEQ ID NO: 3) converts trans-2-enoyl-CoA to R-(−)-3-hydroxyacyl-CoA. The hydratase domain of the yeast multifunctional protein utilizes a broader chain-length range of substrates than does the hydratase isolated from Aeromonas caviae (Fukui et al. (1998) J. Bacteriol. 180:667-673). Such a hydratase with such a broad substrate range finds use in the production of a wide variety of copolymers in plants.

[0132] Thus, the R-specific enoyl-CoA hydratase of the yeast multifunctional protein can used to produce R-(−)-3-hydroxyacyl-CoA for PHA synthesis in plant peroxisomes. Since the R-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com