Storage device for light bulbs

a storage device and light bulb technology, applied in the direction of transportation and packaging, tray containers, packaging goods types, etc., can solve the problems of weak structural structure of packaging, unselected bulbs are left in disarray, and sorting through available bulbs leaves unselected bulbs in disarray, etc., to reduce the cross section dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

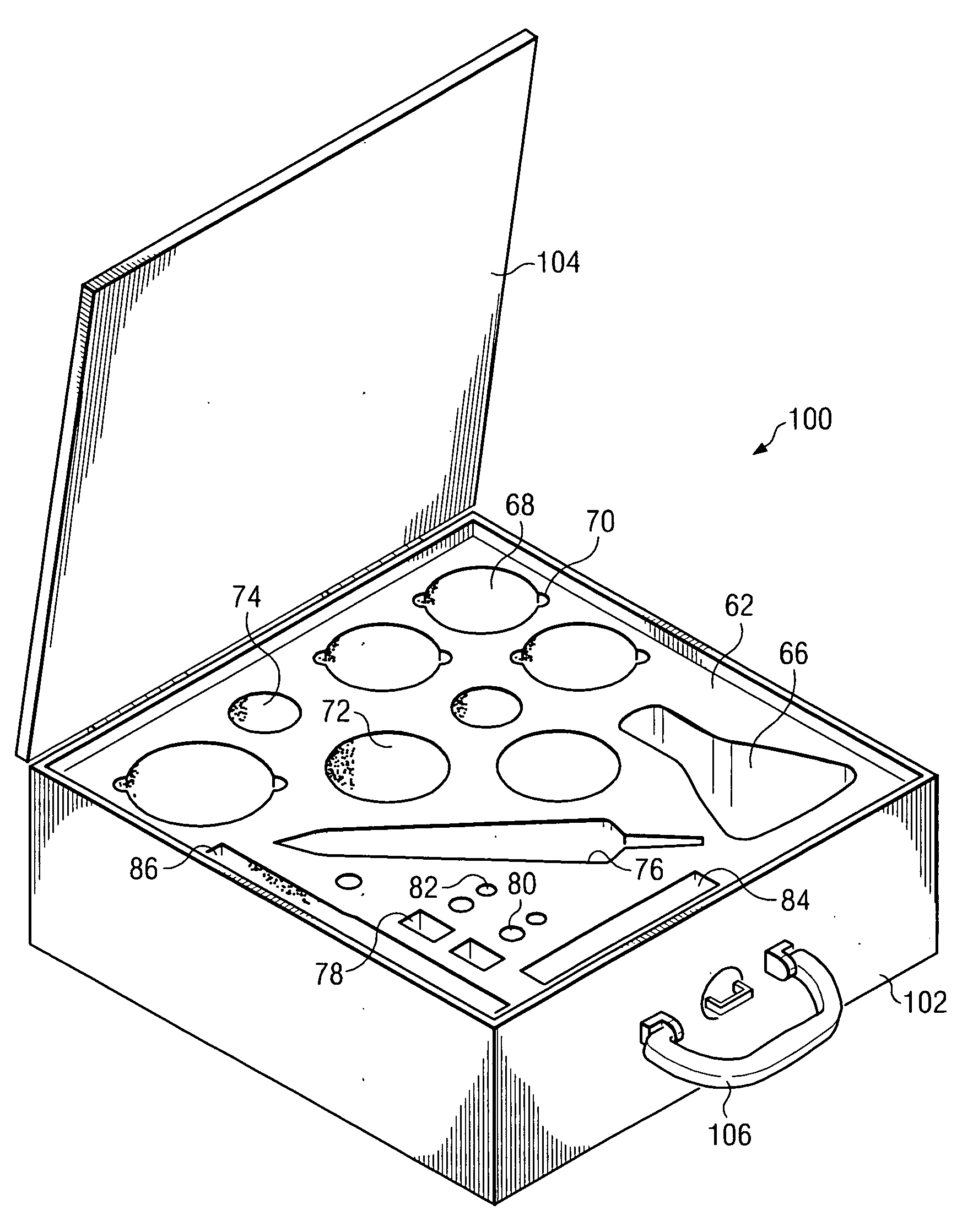

[0018] Referring to FIG. 1, there is illustrated a top plan view of a storage device 10 for light bulbs according to the present invention. A block 12 of resilient material having a density of at least 0.5 pounds per cubic foot (pcf) is shown, the block 12 having a first (top) and a second (bottom) substantially parallel sides and a plurality of cavities formed therein for receiving light bulbs within the cavities. The cavities are shaped generally to correspond to the silhouette or outline shape of the light bulb or other article intended to be stored therein. Further, the cavities are spaced to maximize the storage capacity of the storage device while providing sufficient resilient foam material therebetween for adequate cushioning in the event of impact or compression stresses exerted upon the storage device. The spacing may take advantage of the peculiar shapes of light bulbs by arranging them in alternate orientations.

[0019] The resilient material, which is preferably homogeneo...

second embodiment

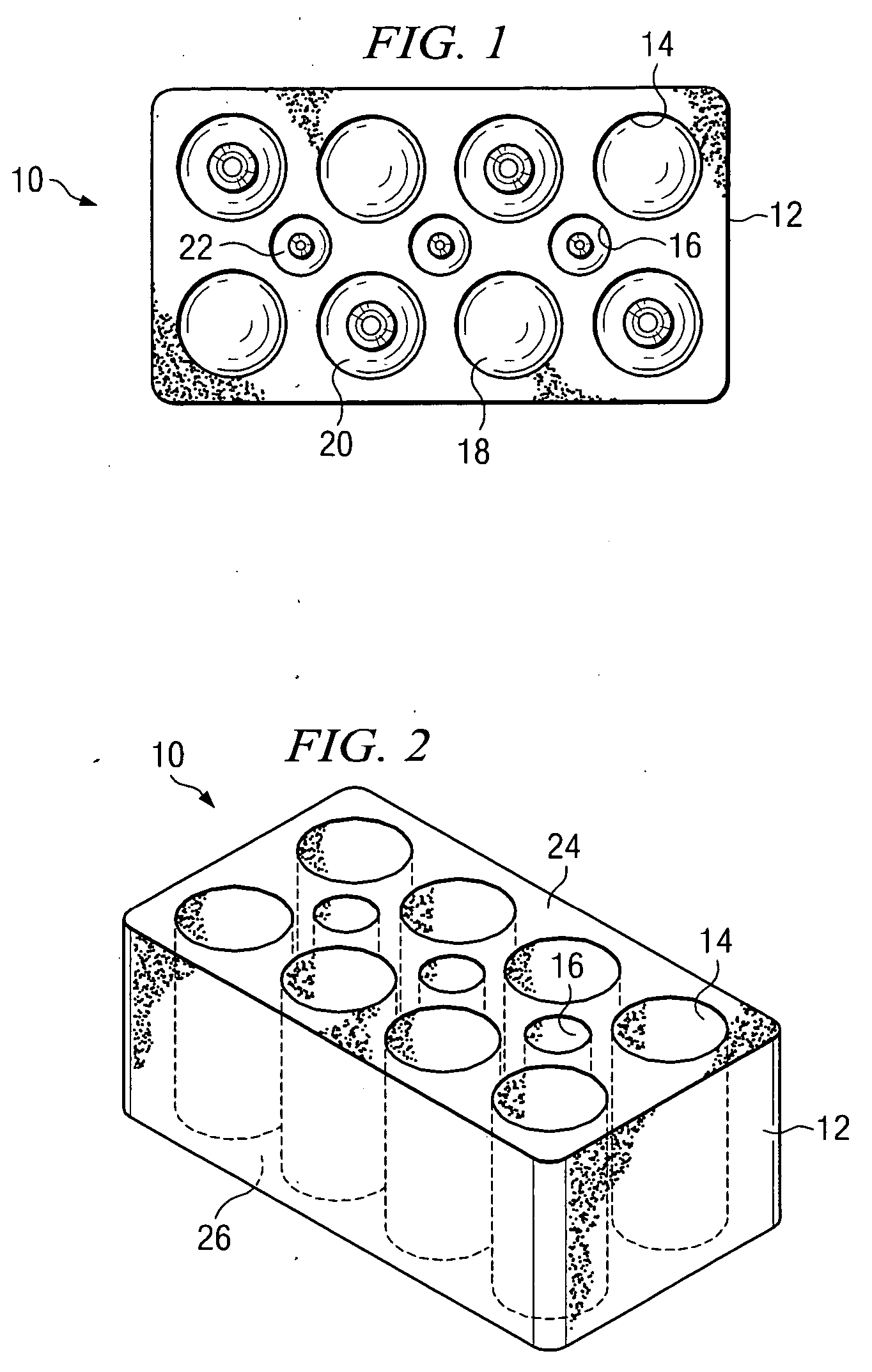

[0025] Referring to FIG. 3, there is illustrated a storage device 30 for light bulbs according to the present invention. The embodiment of FIG. 3 is constructed similarly to the embodiment of FIG. 1 except for its size, its shape, and the arrangement of and variety of light bulbs stored within its cavities. As mentioned in the description for FIG. 1, the first side 54 (see FIG. 4) and second side 56 (see FIG. 4) are generally parallel to each other and will be spaced apart by a predetermined distance that is at least the same as or slightly greater than the largest dimension or diameter of the bulbs to be stored therein. The foam block 32 is also larger to accommodate more bulbs. The foam block 32 may be shaped to fit within a storage container (not shown). When used, a storage container (not shown, but see, e.g., FIG. 7) may be constructed of a transparent material for inspection of the contents without opening the container.

[0026] The cavities in the storage device 30 shown in FIG...

third embodiment

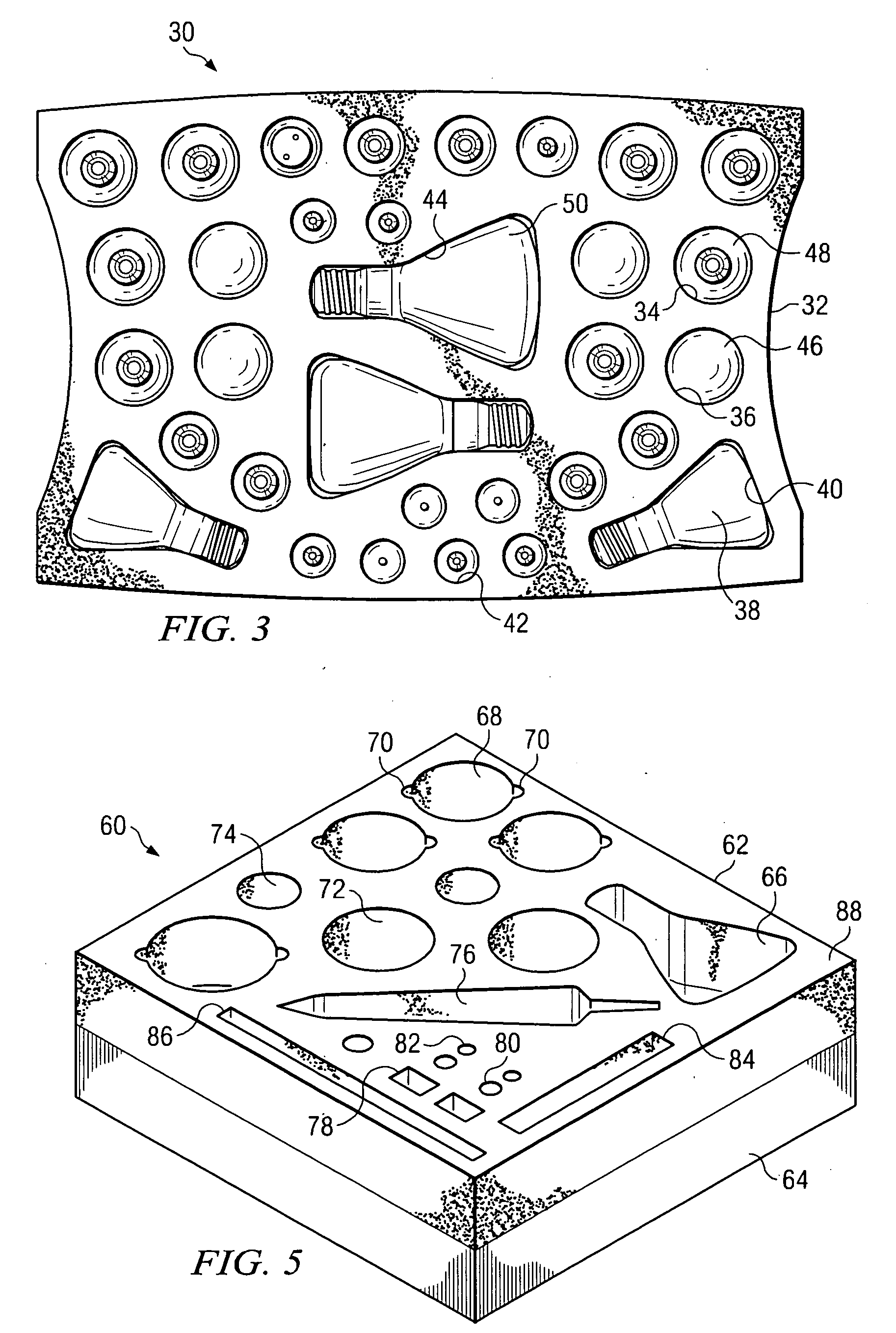

[0028]FIG. 5 illustrates a storage device 60 for light bulbs and associated supply articles for maintaining a residential or office habitation according to the present invention. The storage device 60 of FIG. 5 is constructed of a first layer 62 and a second layer 64. The first layer is preferably fabricated from polyurethane (PU) foam, e.g., by die cutting or other process well known in the art. Cavities of various sizes and shapes to accommodate light bulbs and other articles are provided. The PU foam should have a density of at least 0.5 pcf and preferably in the range of 0.8 pcf to 1.5 pcf. The second layer 64 may be fabricated of PU or other materials such as expanded polystyrene (EPS) foam. EPS foam is a light weight material that is also rigid; that is, it lacks the same property of resilience that is found in the PU foam material. Thus, the EPS material may be utilized as a base or floor of a storage system, as will be described. The density of the EPS used in the second lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com