Sweet potato compositions

a technology of compositions and sweet potatoes, applied in the field of sweet potato flour compositions, can solve the problems of affecting the flavor and texture of snack products, fabricated snack products lack the consumer's preferred sweet taste and nutritionally beneficial high fiber content, and achieve the effect of absorbing less fat and high in vitamins and fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 , 2

Examples 1, 2

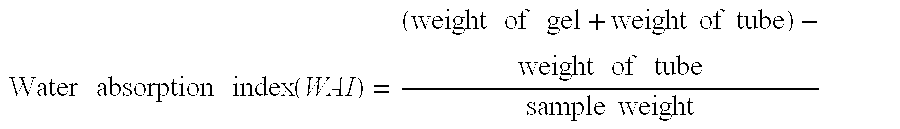

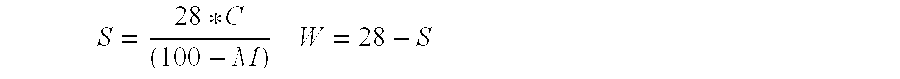

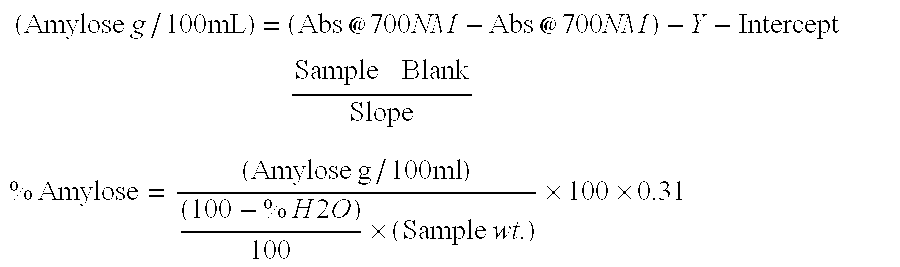

[0288] The following examples illustrate physical properties of the sweet potato flour compositions of the present invention.

TABLE 1Sweet Potato Flour Compositions and Their Physical PropertiesSweet Potato flourcompositionExample 1Example 2Sweet Potato Flake600(Confoco, Elizabeth, NJ)Sweet Potato Powder40100(FDP, Santa Rosa, CA)WAI6.54.5Moisture Content (%)5.06.5Peak Viscosity (RVA)5231.2Final Viscosity (RVA)6045.5

examples 3 , 4

Examples 3,4

[0289] Dough compositions are prepared from the dry blends set forth in the Table 2 below. The dough compositions of Examples 3 comprise 65% dry blend and 35% added water. All ingredients are blended in a Turbulizer® mixer to form a loose, dry dough.

[0290] The dough is sheeted by continuously feeding it through a pair of sheeting rolls forming an elastic continuous sheet without pin holes. Sheet thickness is controlled to about 0.02 inches (0.05 cm). The back roll is heated to about 90° F. (32° C.) and the front roll is heated to about 135° F. (57° C.).

[0291] The dough sheet is then cut into oval shaped pieces and fried in a constrained frying mold at about 400° F. (204° C.) until desired doneness is achieved. The frying oil is a 50 / 50 blend of cottonseed and corn oils. The fried pieces contain about 20-25% fat.

[0292] These products have a crisp texture, fast mouth-melt and a sweet and brown complex flavor.

[0293] The dough composition of Example 4 comprises 65% dry b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com