Method of cleaning and sterilizing endoscopic camera equipment, etc. and apparatus therefor

a camera and endoscopic technology, applied in the field of methods and apparatus for cleaning and sterilizing endoscopic cameras, etc., can solve the problems of increasing production costs, large installation space of apparatus, and inability to have such convenience of apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

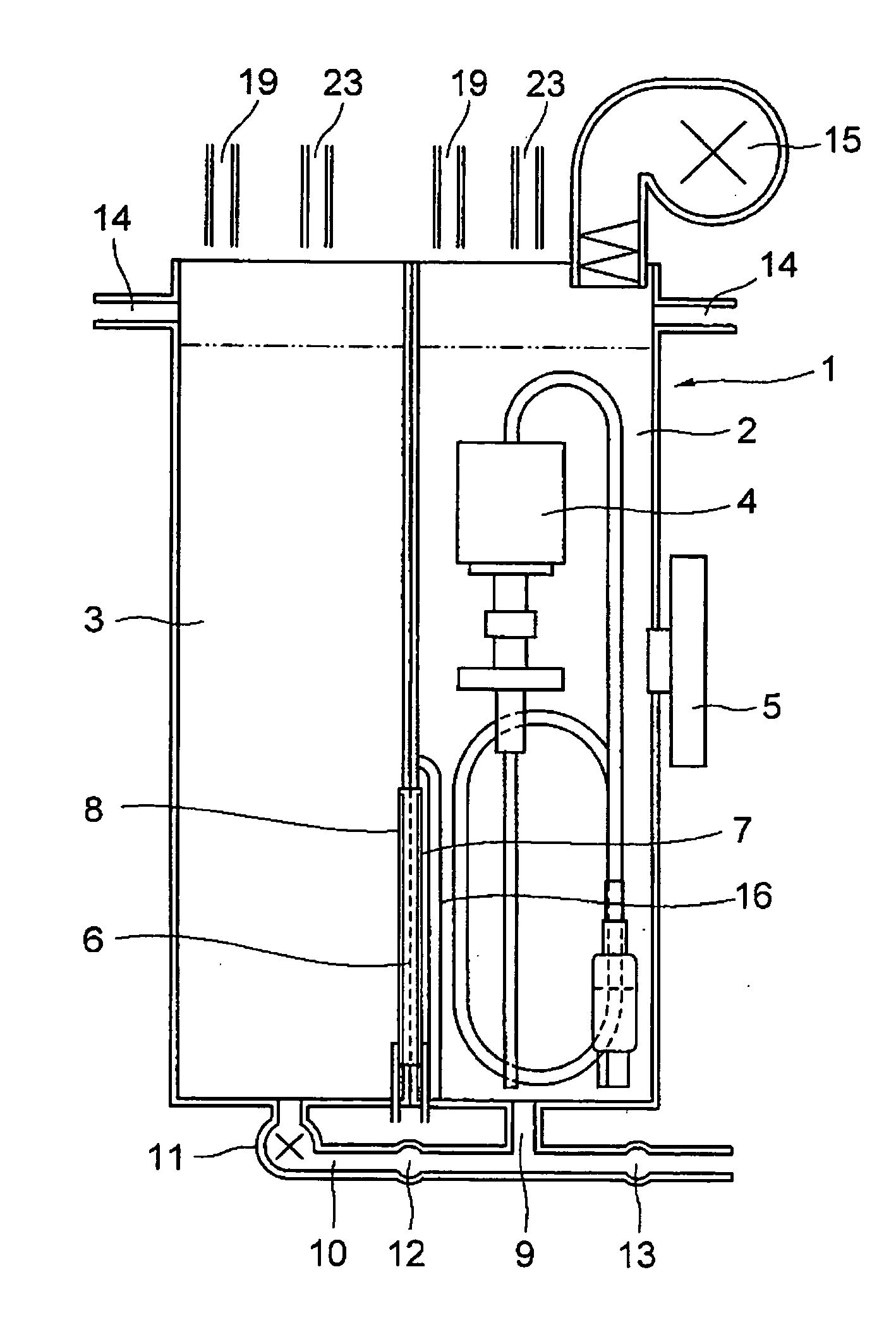

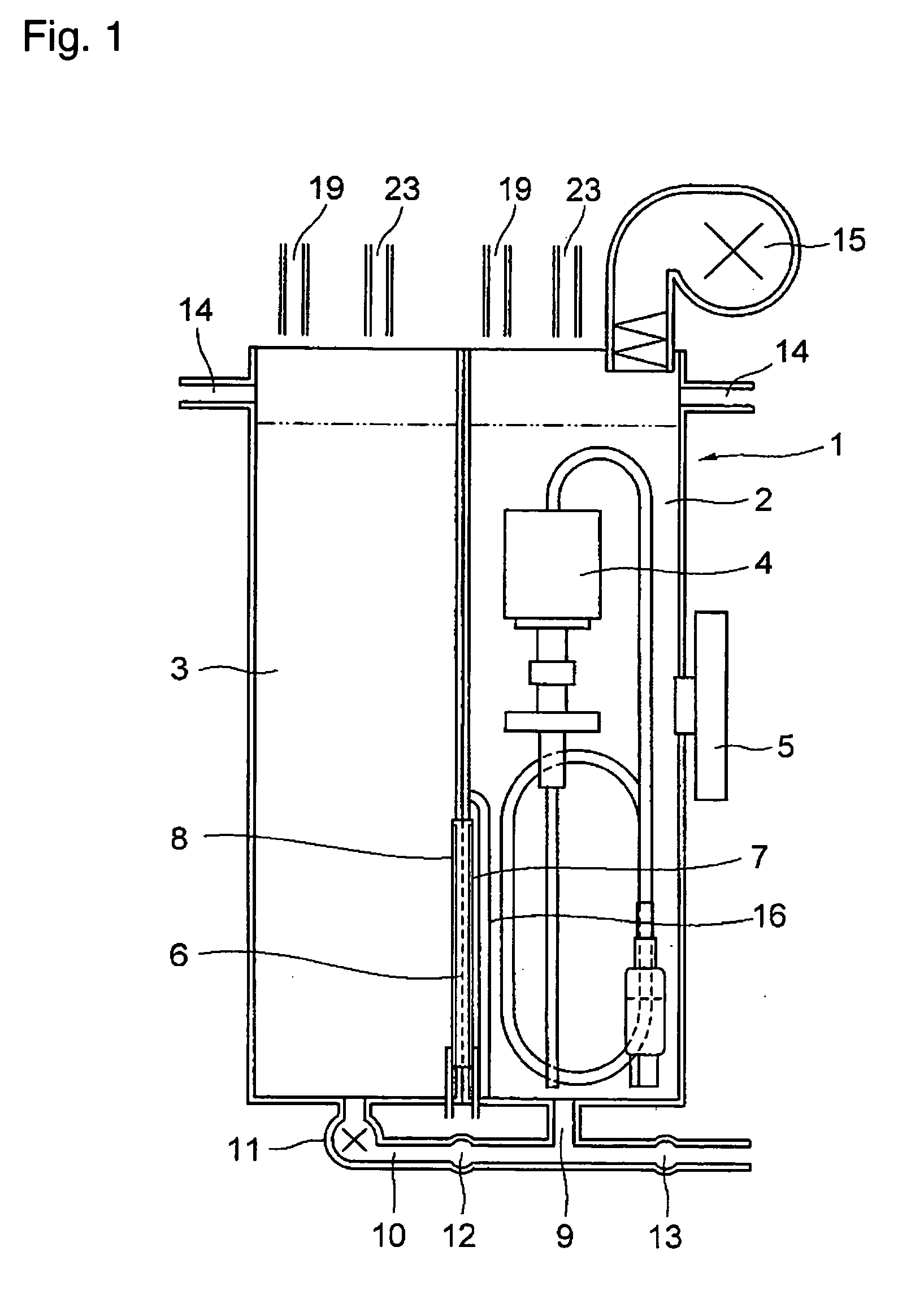

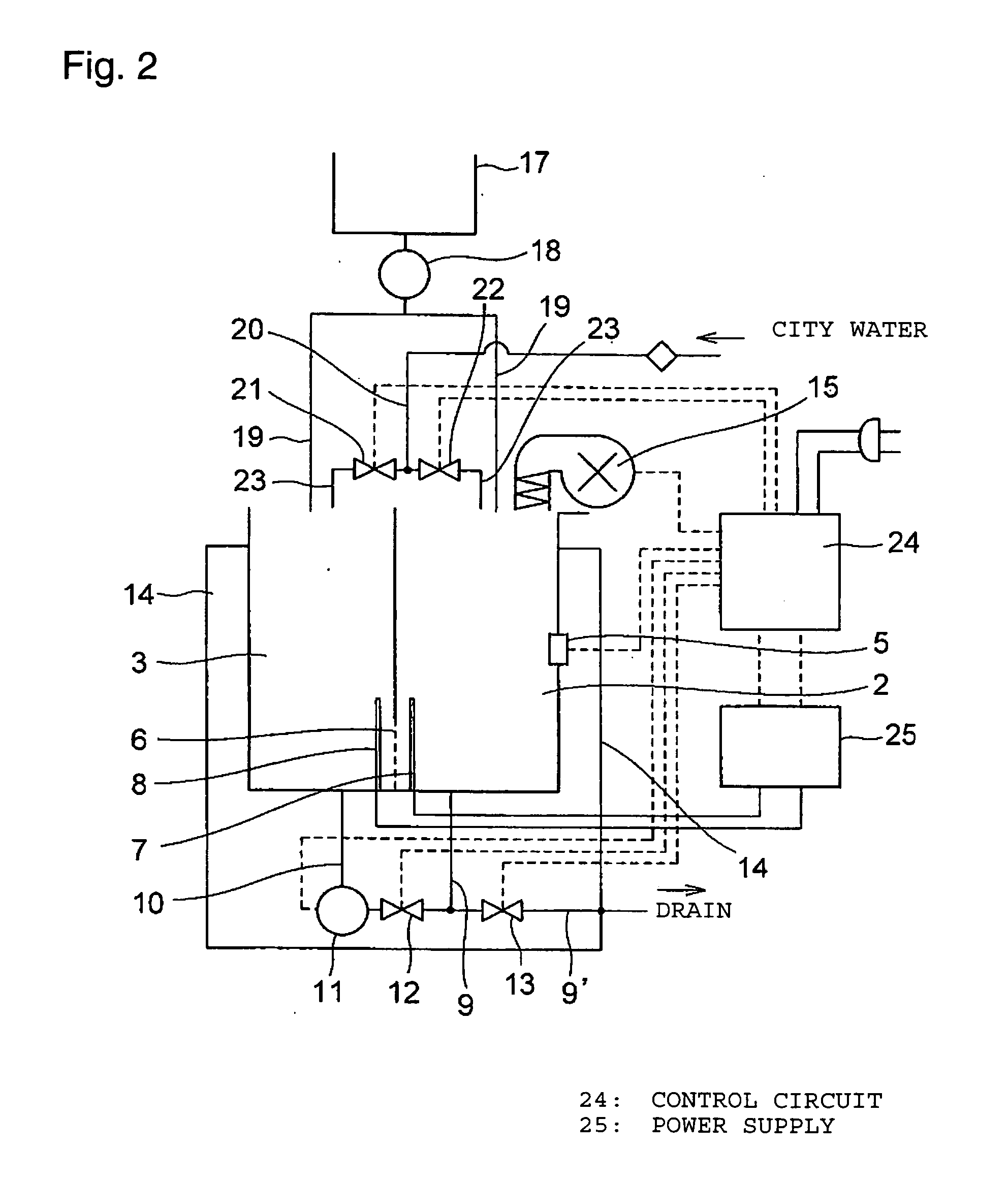

Image

Examples

Embodiment Construction

[0048] Objects to be cleaned and sterilized by the present invention includes endoscopic camera instruments including endoscopes, cameras attached to the endoscopes and other peripheral devices, and operation tools such as forceps, and implants. An endoscopic camera instrument etc. in the present invention is a generic name of these. Further, an endoscope includes both of hard type and soft type.

[0049] Therefore, an endoscopic camera instrument means each of an endoscope and its peripheral devices, or a combination of them. Further in a case of a soft type endoscope requiring cleaning of inside of its conduit, the endoscope and peripheral devices to be attached to this are cleaned in a state that they are separated. On the other hand, in a case of a hard type endoscope not requiring cleaning of inside of its conduit, it can be cleaned in a state that a camera and peripheral devices such as camera cables and optical cable connectors are connected to a main unit attached with an inse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| acidic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com