Contact grid array system

a grid array and contact technology, applied in the field of elastic electric contacts, can solve the problems of increasing the electrical, reliability requirements of these electrical contacts, the inability to make separable electrical contacts with contacts of miniature electronic circuits, and the inability to meet the requirements of electrical and reliability, and no particular contact design appears to provide all the properties required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

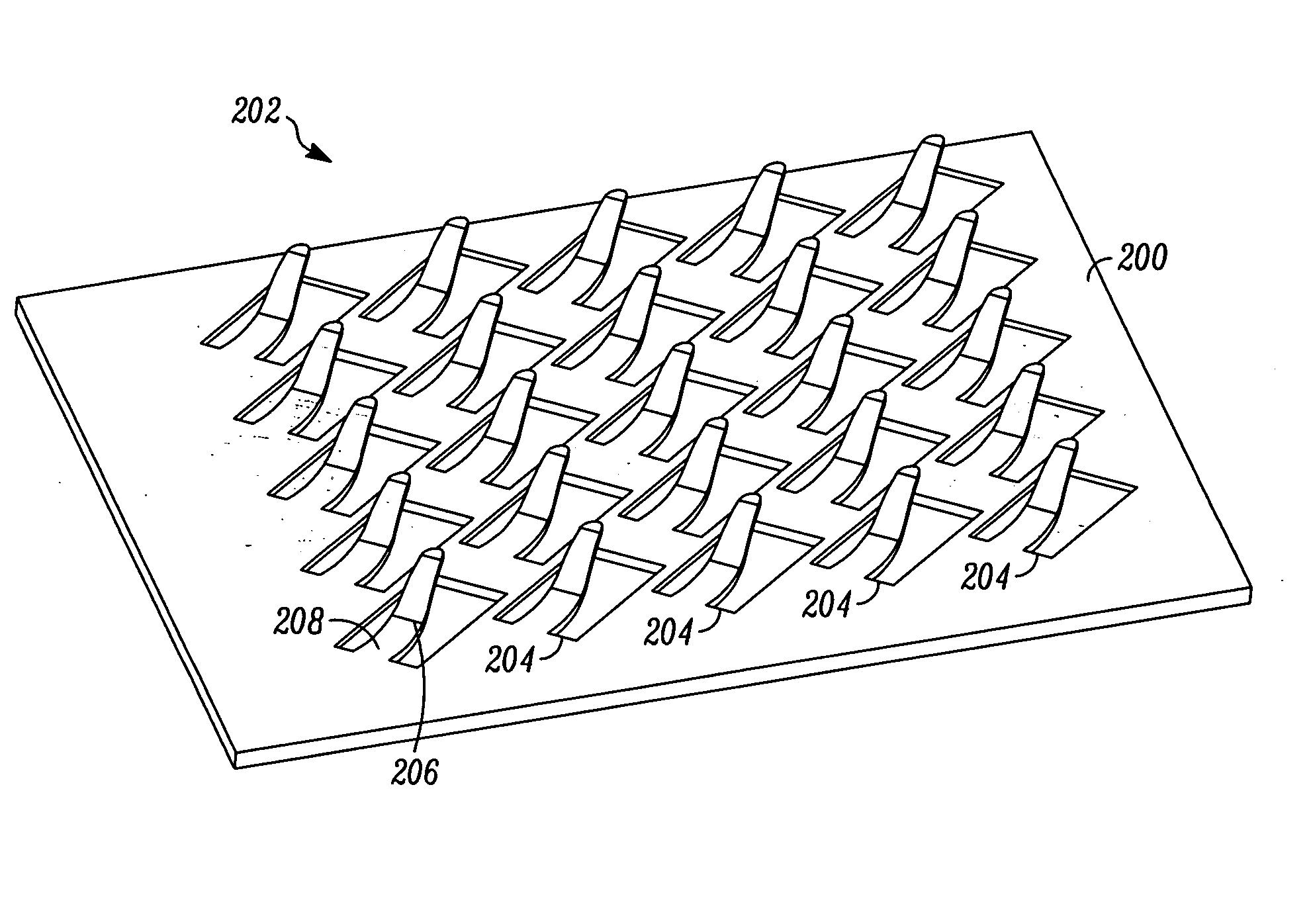

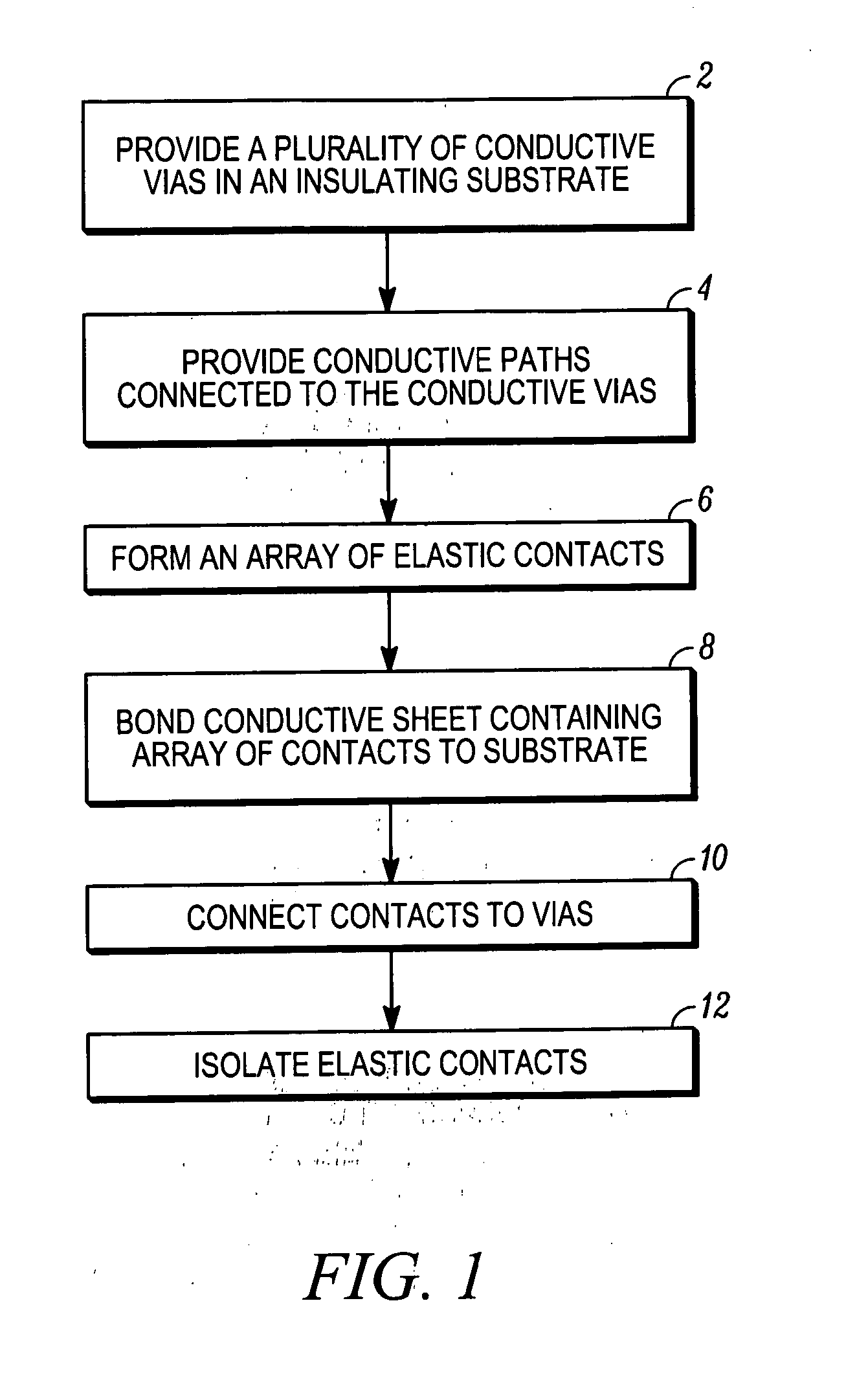

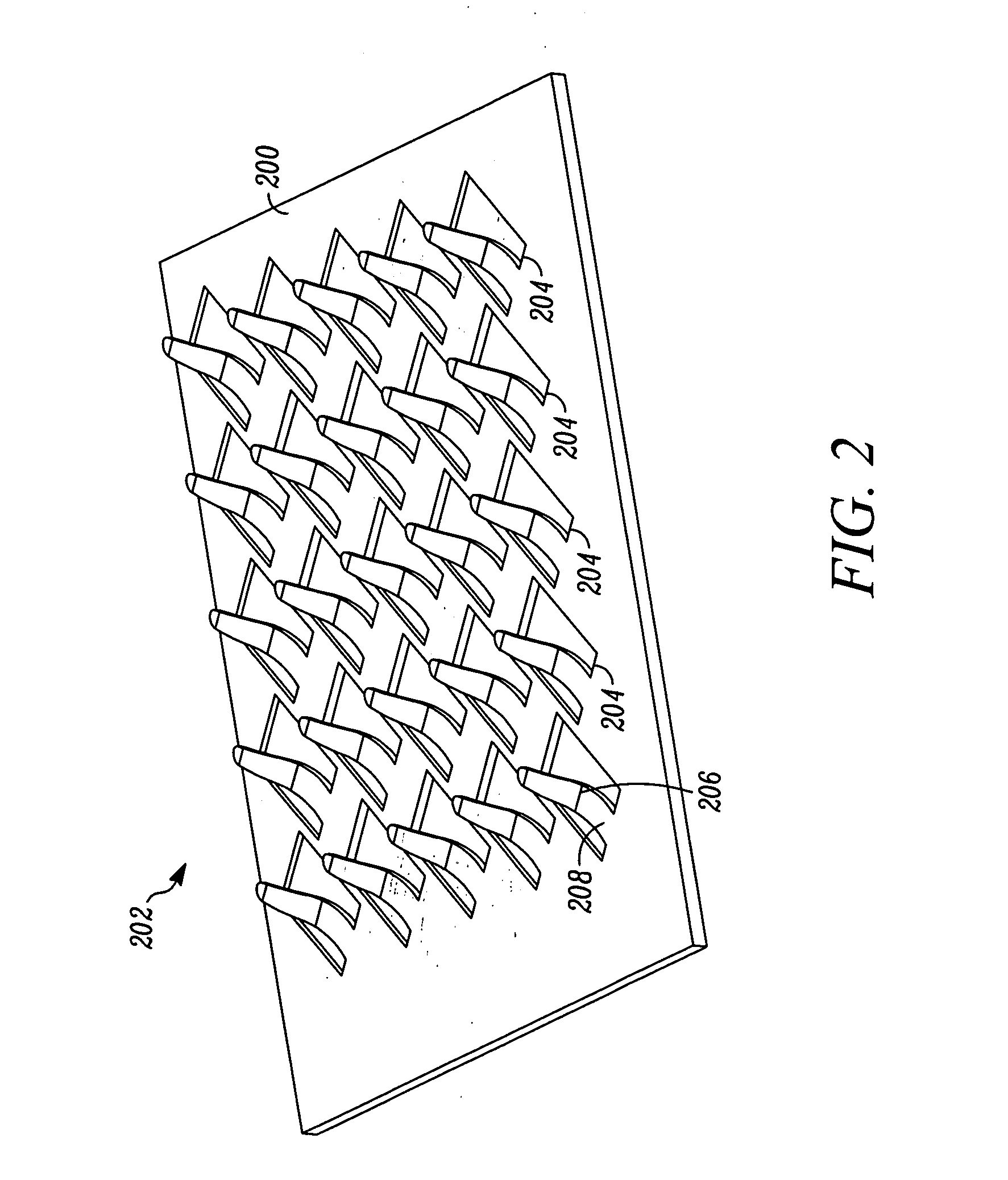

[0053] Aspects of the present invention are related to methods for fabricating electrical connectors by lithographic patterning of metallic layers to form an array or arrays of contact elements. The metallic layers can be applied to a connector substrate before patterning to form the contact elements, or can be free standing layers that are subjected to patterning before joining to the connector substrates. In general, the contacts can be formed from a single layer of metallic material, but can also be formed from multiple layers of the same material, or of different materials, in which one or more layers can be added to the contacts after a metallic layer is patterned to form a contact array. Connectors formed by these methods include substrates having a contact array disposed on a single side, or having contact arrays disposed on both sides, such as interposers.

[0054] Connector elements and interposer layers fabricated according to aspects of the present invention can be produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com