Modular surfacing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

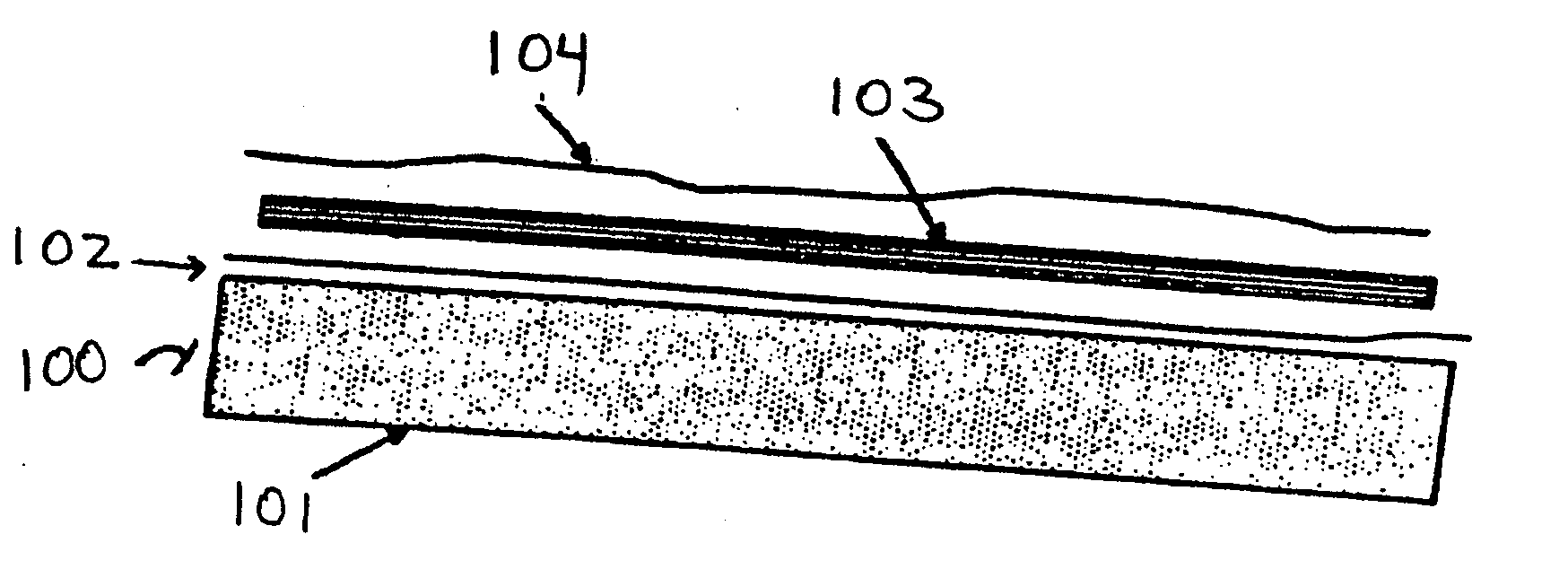

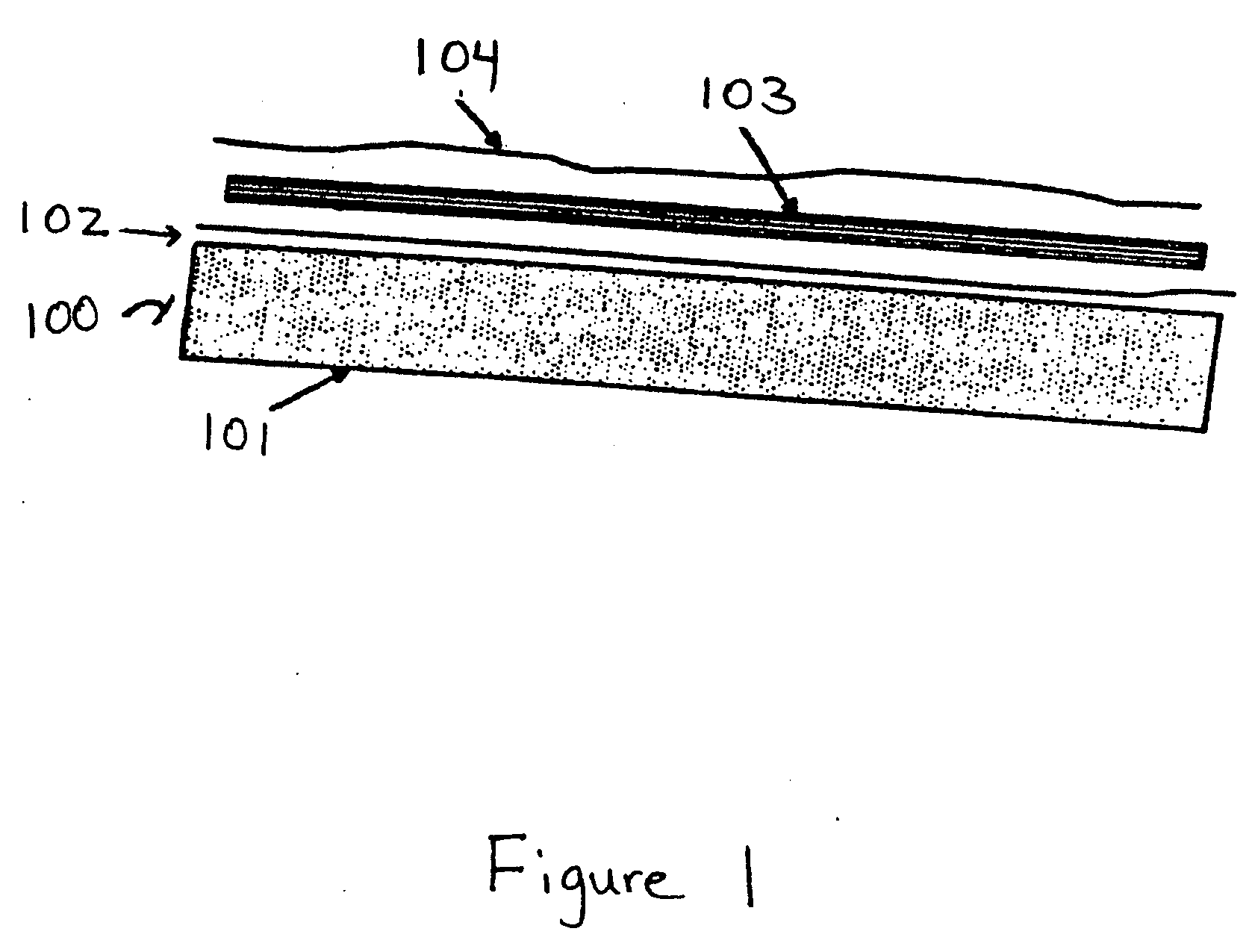

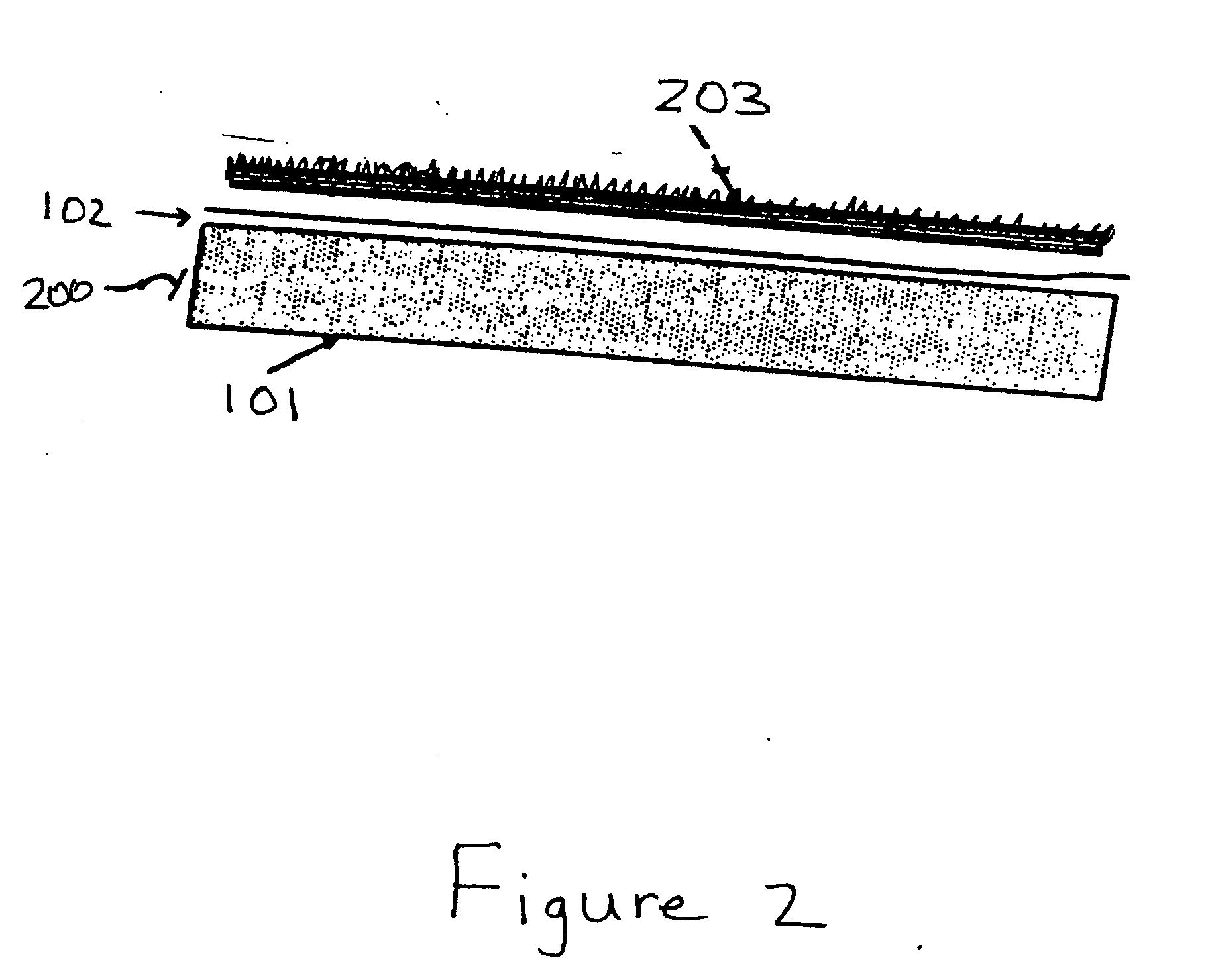

Image

Examples

Embodiment Construction

[0002] 1. Field of the Invention

[0003] The present invention relates generally to surfacing systems, and more particularly to a modular surfacing system for use in recreational, institutional and other applications.

[0004] 2. Background of the Invention

[0005] Many factors are taken into consideration when selecting flooring and surfacing products for use in recreational and institutional settings. Such factors may include cost, ease of installation, durability, and aesthetics. In addition, safety and handicap accessibility are also often considered. Conventional flooring and surfacing systems are often exhibit poor characteristics with regard to at least one of these factors.

[0006] In playground and recreational settings, most injuries occur when people fall from playground equipment from a height of 3 to 10 feet onto the ground. To reduce the severity of these injuries, the U.S. Consumer Products Safety Commission (CPSC) has issued guidelines that playground safety surfacing mus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com