Renewable fuel/lubricant mixture for use in a two-stroke internal combustion engine

a technology of internal combustion engine and lubricant mixture, which is applied in the direction of lubricant composition, liquid carbonaceous fuel, fuel, etc., can solve the problems of increased horsepower at the price of increased concentration of pollutants in the exhaust gas, mtbe is a suspected hazard to human health, and unused fuel, lubricant, and lubricant are released in the exhaust stream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

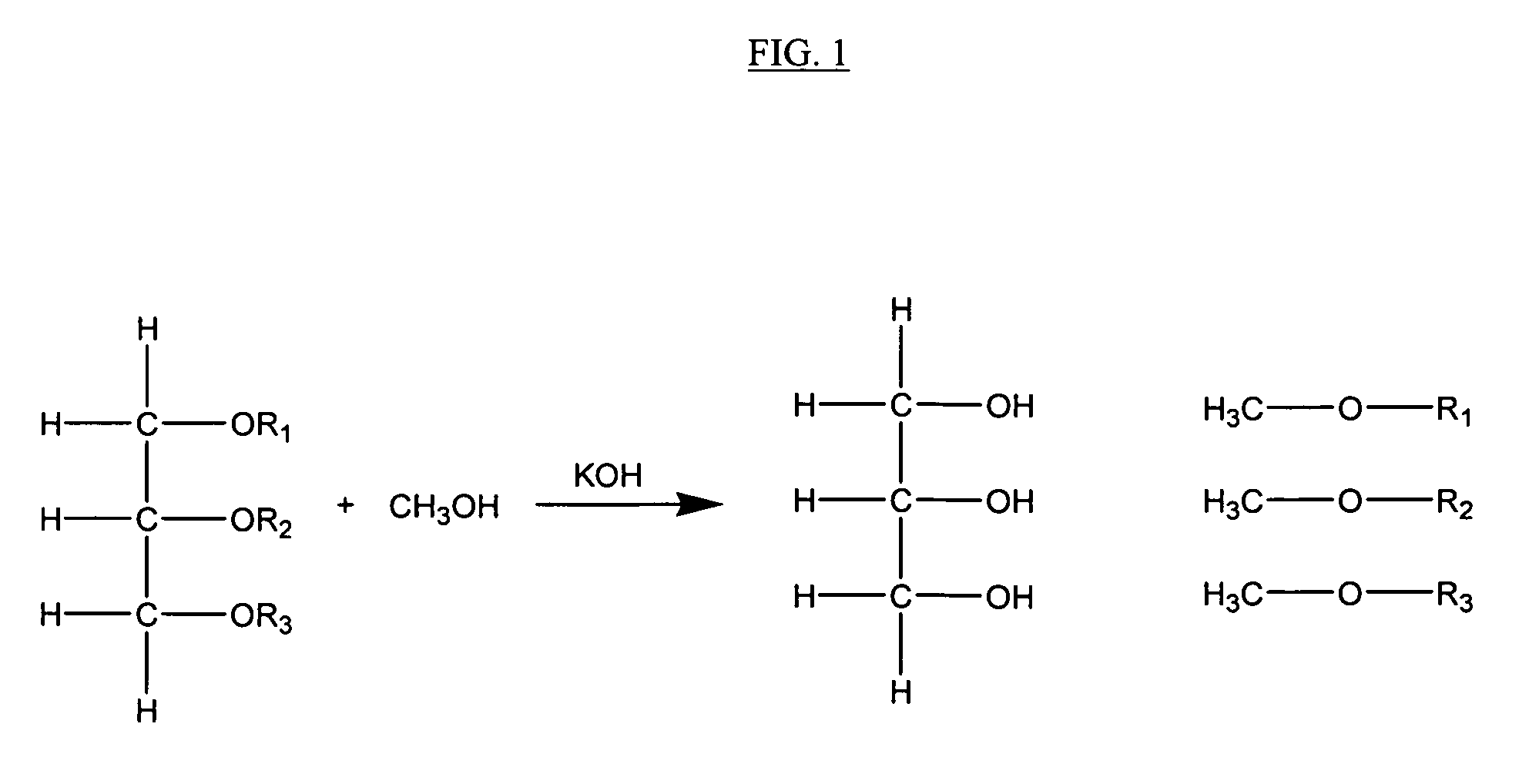

[0010] Provided is a fuel / lubricant formulation for the operation of two-stroke engines with improved emissions and performance. The fuel mixture is comprised primarily of a fuel and a lubricant. Both the fuel and lubricant are completely renewable and environmentally friendly. The fuel component of this mixture may include alcohols, ethers, ketones, gasoline, alcohol / gasoline blended fuels, nitromethane, or any combination of these fuels while the lubricant portion of the mixture includes one or more lipids, biodiesel, fatty acid alkyl esters, free fatty acids, or any combination thereof.

[0011] The composition of the lubricating fuel to be used in the engine may range from 40% to less than 100% by weight of alcohols, ethers, ketones, alcohol / gasoline blended fuels, gasoline, nitromethane, or any combination of these fuels and greater than zero to 60% by weight lipids, biodiesel, fatty acid alkyl esters, free fatty acids, or any combination thereof. These fuel / lubricant mixtures ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com