Deicing composition

a composition and composition technology, applied in the field of deicing compositions, can solve the problems of significant traffic and safety problems, corrosive metals like iron, copper, aluminum, chlorides can be harmful to the environment, etc., and achieve the effect of moderate asr-aggravating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

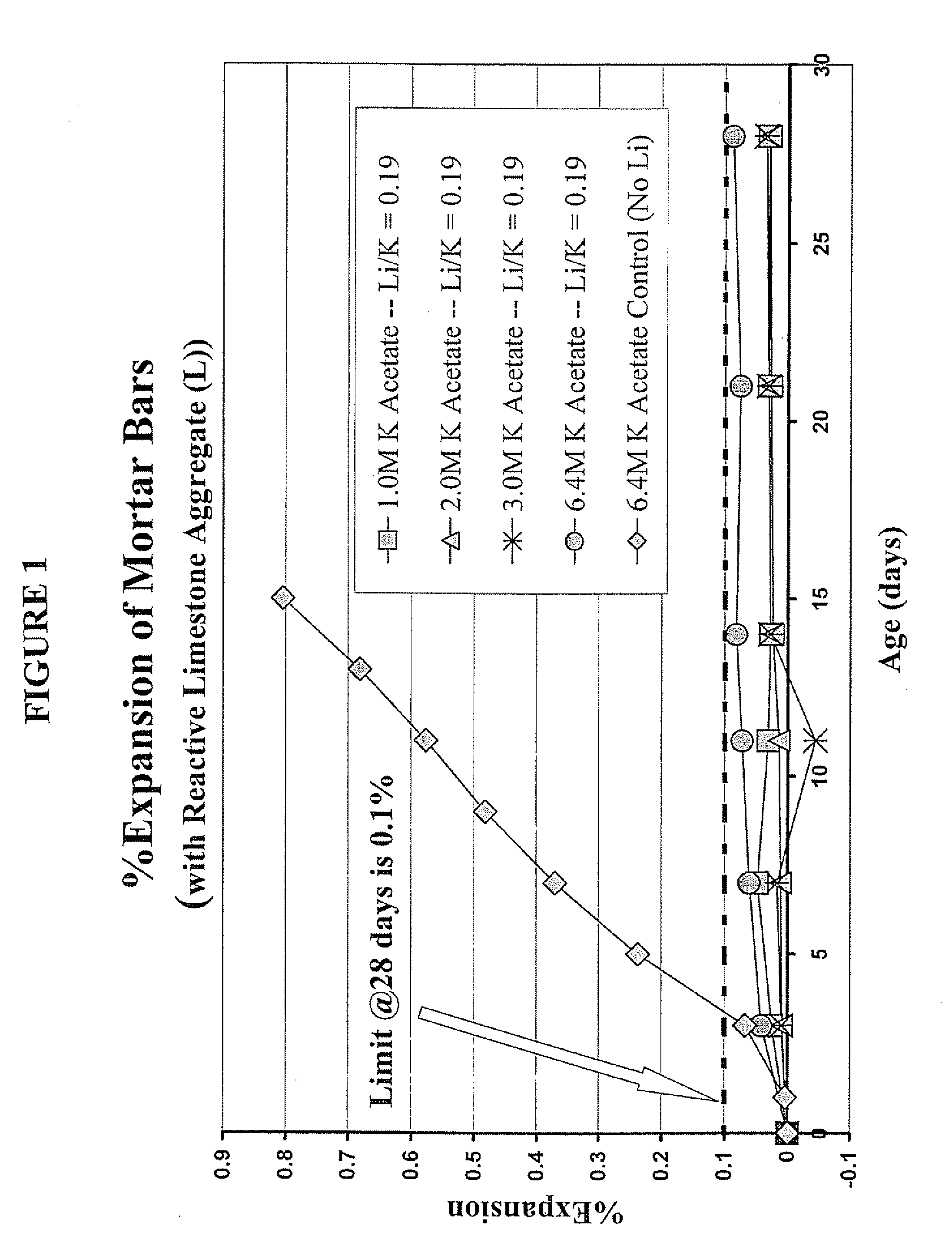

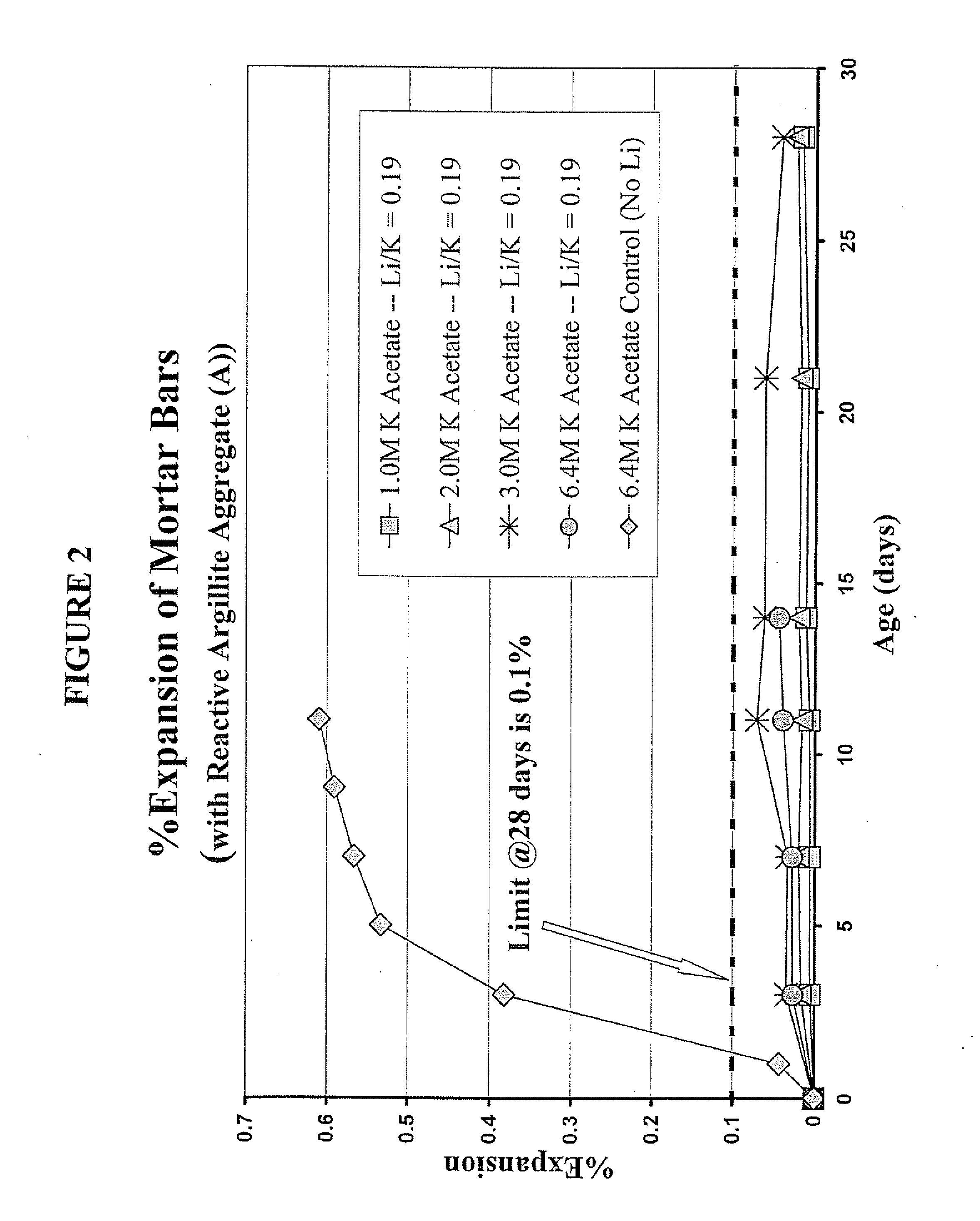

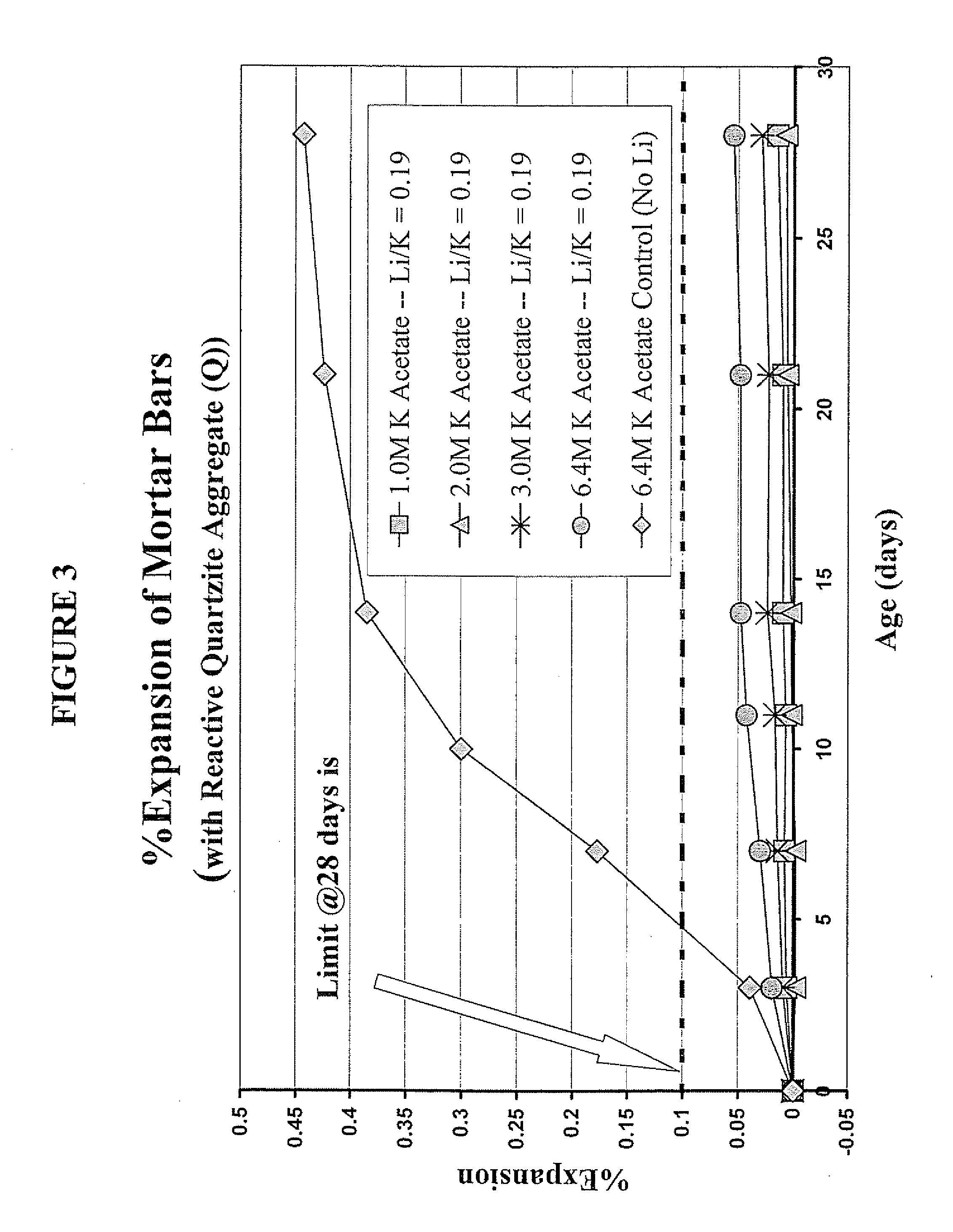

[0031] To demonstrate the effectiveness of the lithium portion of the deicer composition, the following experiments were conducted Mortars incorporating four different aggregates were cast into ASTM C 1260-type bars using ASTM C150 Type 1, high alkali (0.82% Na2Oeq) cement. The aggregate types were a limestone (“L”), a rhyollite (“R”), an argillite (“A”), and a quartzite (“Q”), and all have demonstrated deleterious ASR reactions in actual concrete structures in the field. Controls of 50 percent (6.4M) potassium acetate were used, and the mortar bars were stored in these solutions, and duplicates in the solutions described below, at 80° C. FIGS. 1-4 show the percent expansion versus age data for the mortar bars stored in the various concentrates (1M, 2M, 3M, 6.4M) of potassium acetate and with solutions incorporating lithium nitrate at a molar ratio of Li / K of 0.19. FIGS. 5-7 show the percent expansion versus age data for the mortar bars stored in the various concentrates (1M, 2M, 3M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com