Electrokinetic Infusion Pump System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

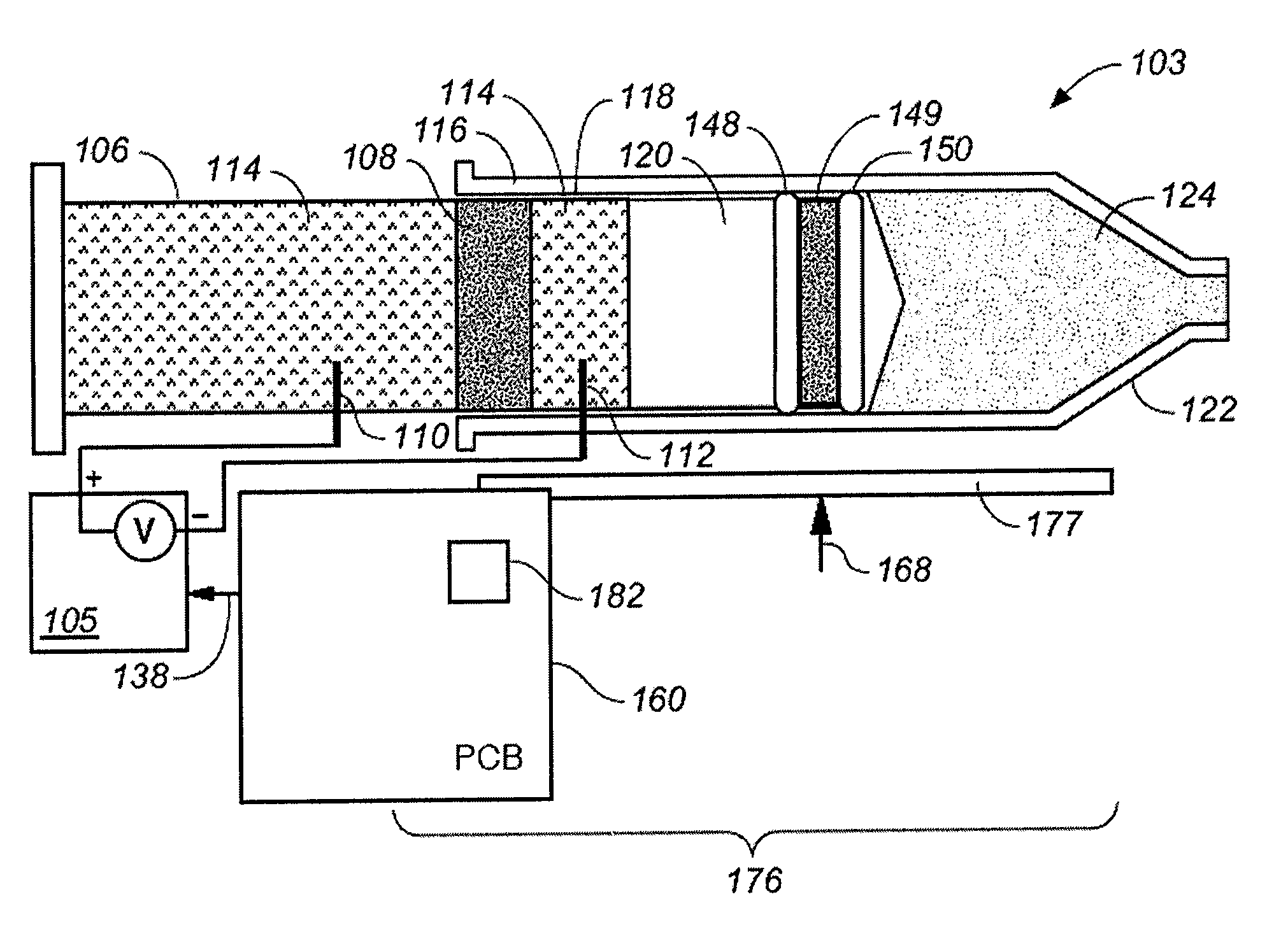

[0137] As mentioned previously, when designing an electrokinetic infusion pump with closed loop control 1100, the infusion module 1104 and the electrokinetic engine 1102 can be integrated, as illustrated in FIGS. 33, 35, 36, 37, and 38, or they can be separate components connected with tubing, as illustrated in FIG. 39. In FIG. 39, electrokinetic infusion pump with closed loop control 1100 includes infusion module 1104 and electrokinetic engine 1102, connected by connection tubing 1244. Infusion module 1104 includes moveable partition 1120 and infusion reservoir outlet 1123. The moveable partition 1120 includes moveable permanent magnet 1149. Further details regarding electrokinetic engine 1102, including materials, designs, and methods of manufacturing, suitable for use in electrokinetic infusion pump with closed loop control 1100 are included in U.S. patent application Ser. No. 10 / 322,083, previously incorporated by reference. Using electrokinetic infusion pump with closed loop co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com