Foldable support leg and pallet assembly formed therefrom

a support leg and pallet technology, applied in the field of pallet assemblies, can solve the problems of heavy wooden pallets, serious delay and expense for pallet users, and many drawbacks of wooden pallets, and achieve the effect of enhancing the structural conformity and load bearing capacity of the support leg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

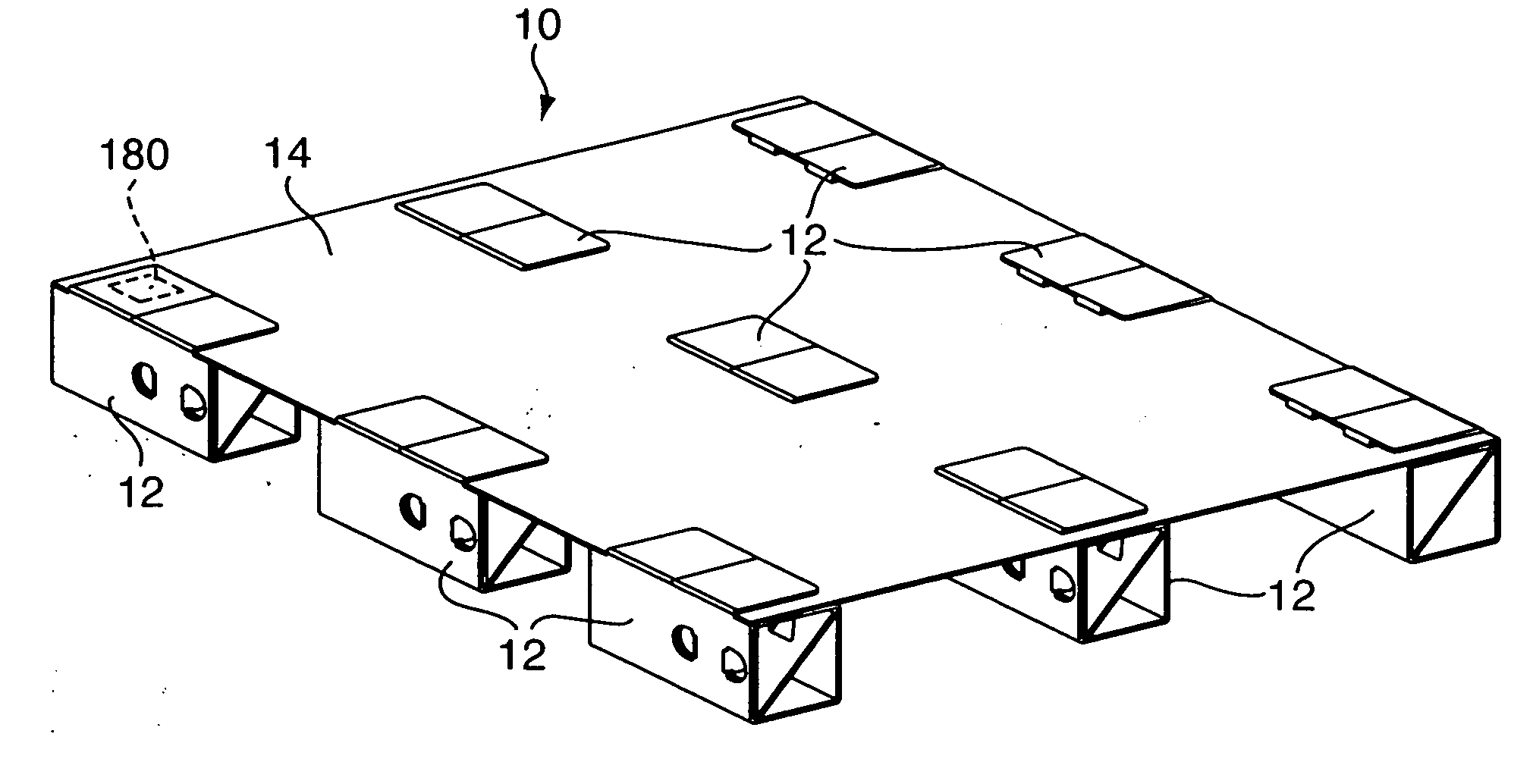

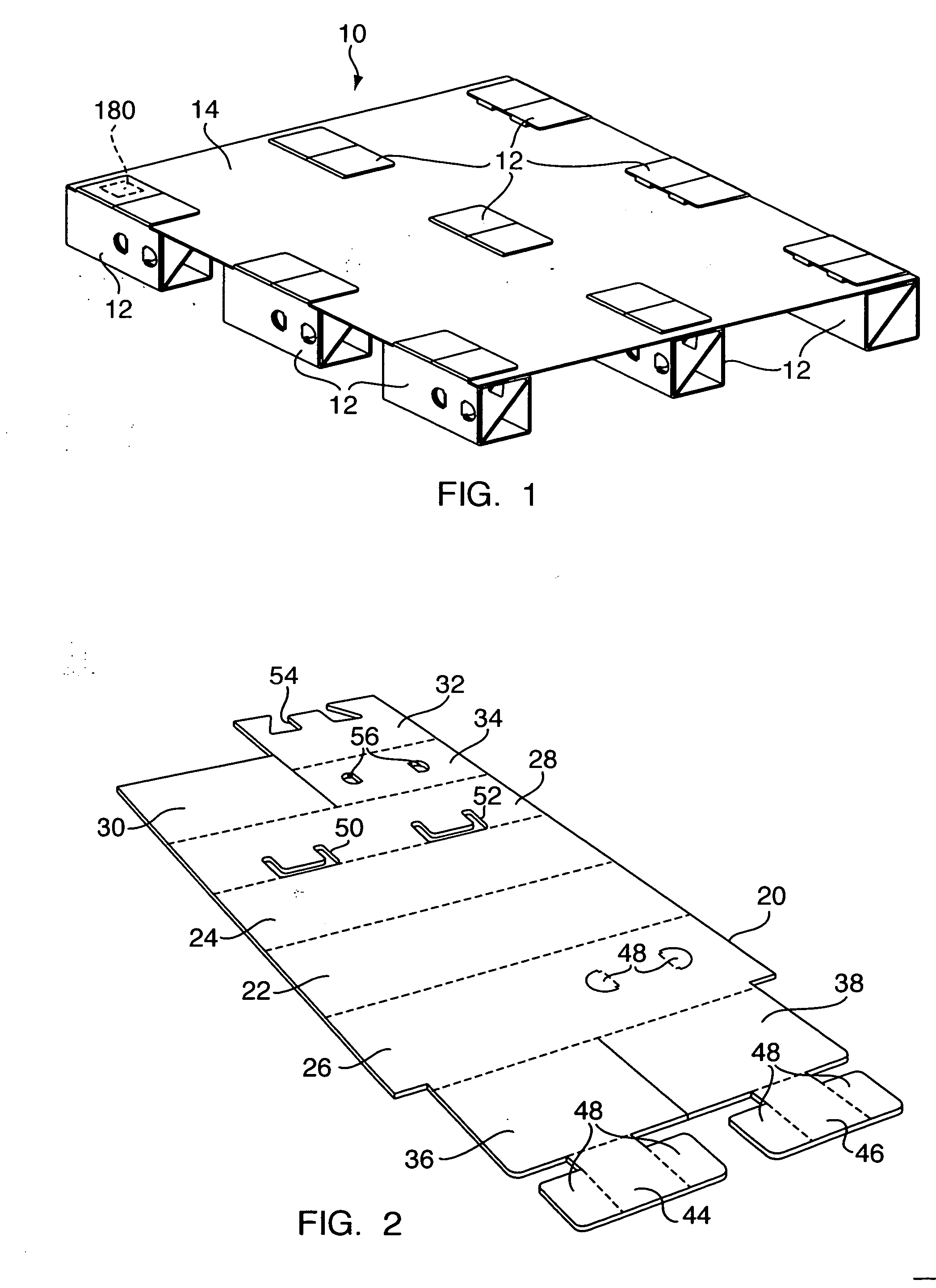

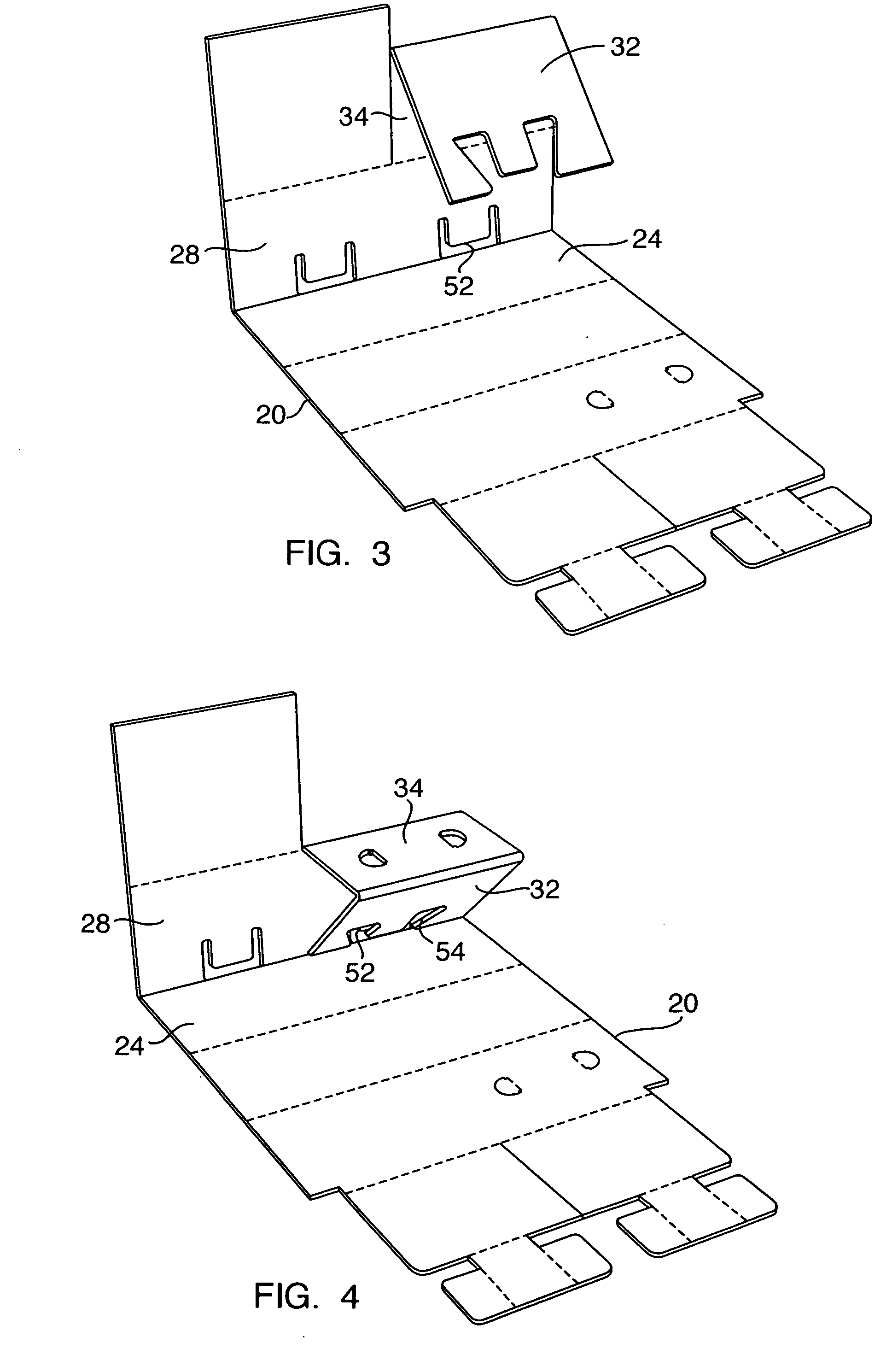

[0025] Referring to FIG. 1, a pallet assembly 10 is formed from a plurality of foldable support legs 12 mated to a pallet deck 14. The support leg will be described in reference to FIGS. 2-9. Referring to FIG. 2, each support leg 12 is folded from a sheet 20 of material. The sheet 20 of material is configured into a sequence of adjacent panels and tabs. The panels include a bottom panel 22, first and second side panels 24, 26, a top panel 28, first and second diagonal panels 30, 32, a diagonal offset panel 34, and first and second deck retention panels 36, 38. Together the panels are all foldable to form a nested panel structure, the top, bottom and side panels 22-28 defining an interior cavity, with the diagonal panels 30, 32 and the diagonal offset panel 34 forming an internal support structure within the cavity, as will be described below. The terms top, bottom and side refer, as used herein, to the orientation of the support leg 12 when mated with the pallet deck 14 during conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com