Secondary air supply system for internal combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

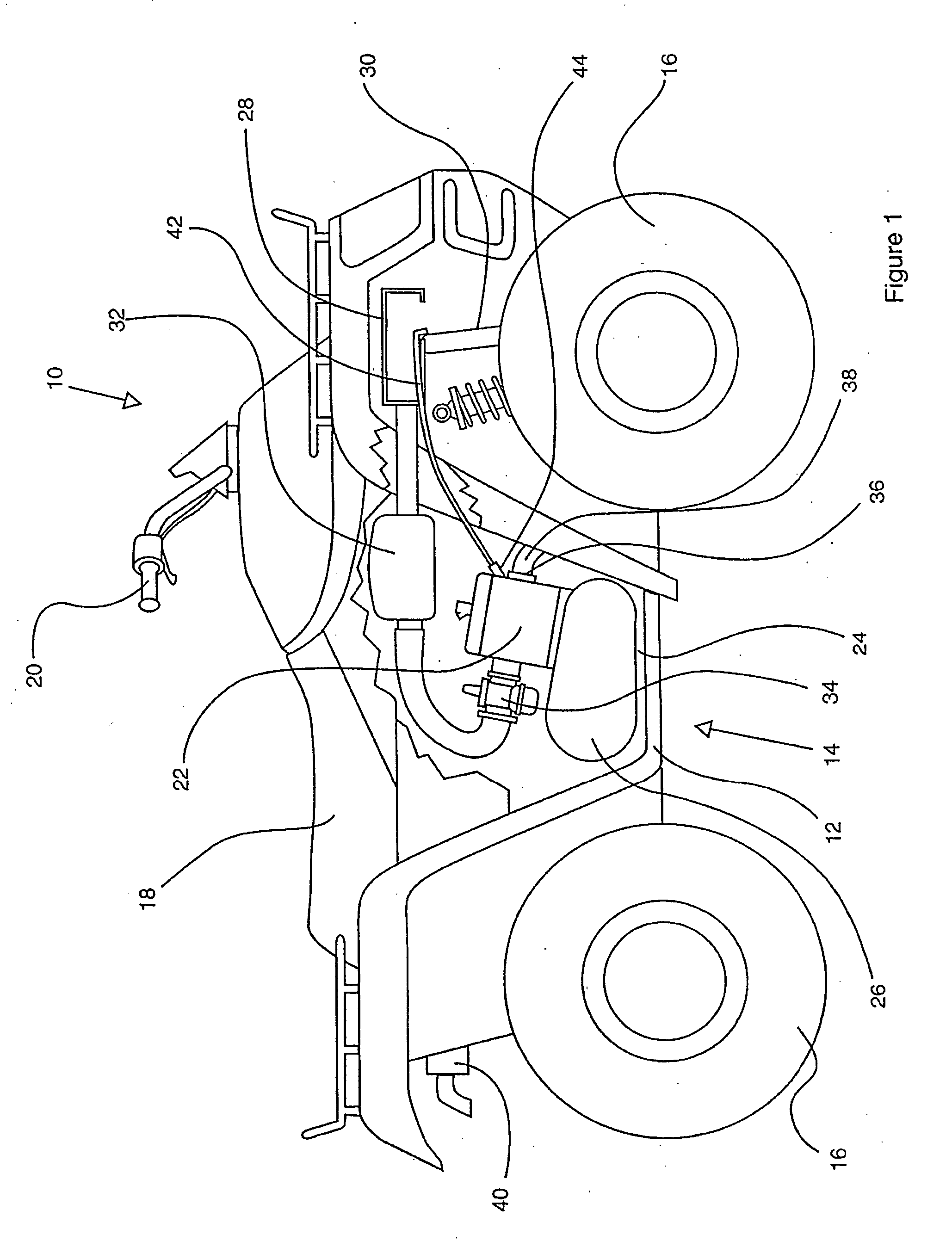

[0019] The present invention is ideally suited for motor vehicles such as all-terrain vehicles (ATVs) as illustrated in FIG. 1 with ATV 10. The invention, however, may be used with any internal combustion engine where cleaner emissions are desired.

[0020] All-terrain vehicle 10 includes a frame 12 holding an engine 14, wheels 16, seat 18, and handlebars 20. A conventional ATV arrangement is thus provided and used as an example herein of how the present invention may be situated for use in a vehicle application.

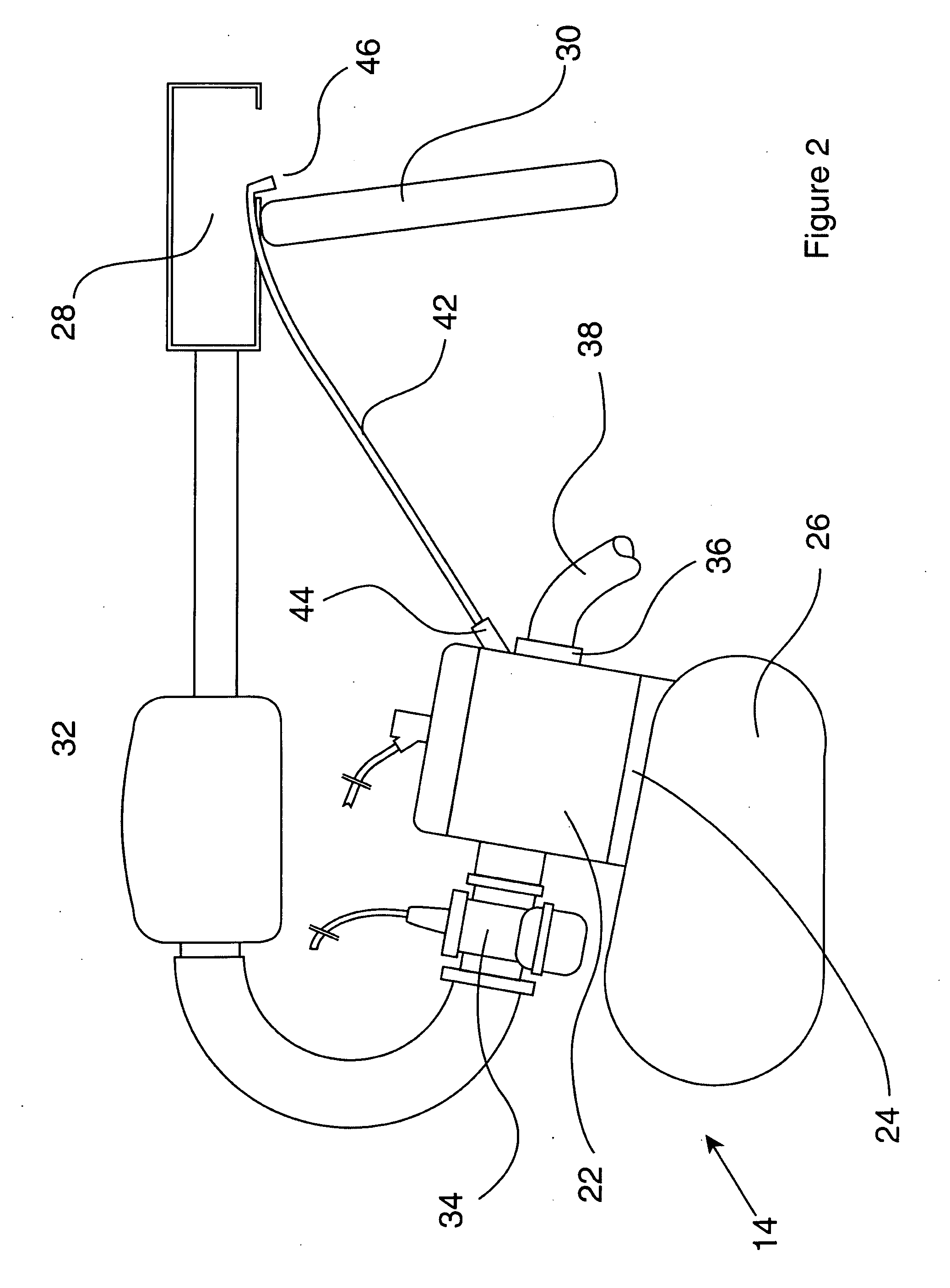

[0021] Engine 14 includes at least one cylinder 22, a crankcase 24, and a clutch compartment 26. Cylinder 22 is generally positioned atop crankcase 24. However, in alternate embodiments, multiple cylinders may be employed in various arrangements with crankcase 24.

[0022] The air intake system of engine 14 as shown in FIGS. 1 and 2 includes an air intake plenum 28 at the forward end of the vehicle. Plenum 28 includes an air inlet in front of a radiator 30. The air inlet of ple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com