Slidable coupling components for shelf management systems

a shelf management system and sliding coupling technology, applied in the field of self-fronting merchandise pusher system, can solve the problems of inadvertent sliding of the coupling, disruption of the product fronting on the shelf, interference between products in adjacent channels, etc., and consume a great deal of time and effort to manage the produ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

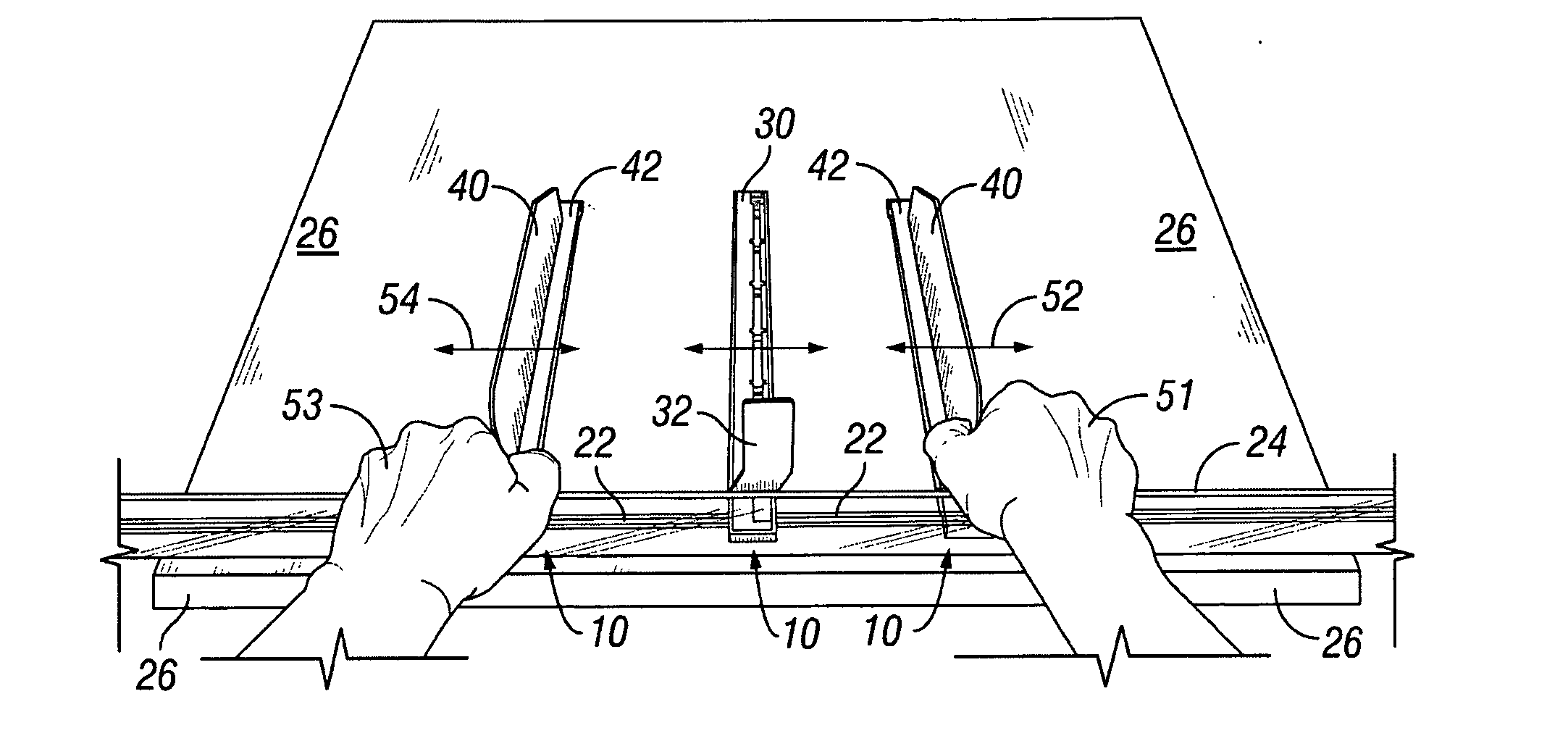

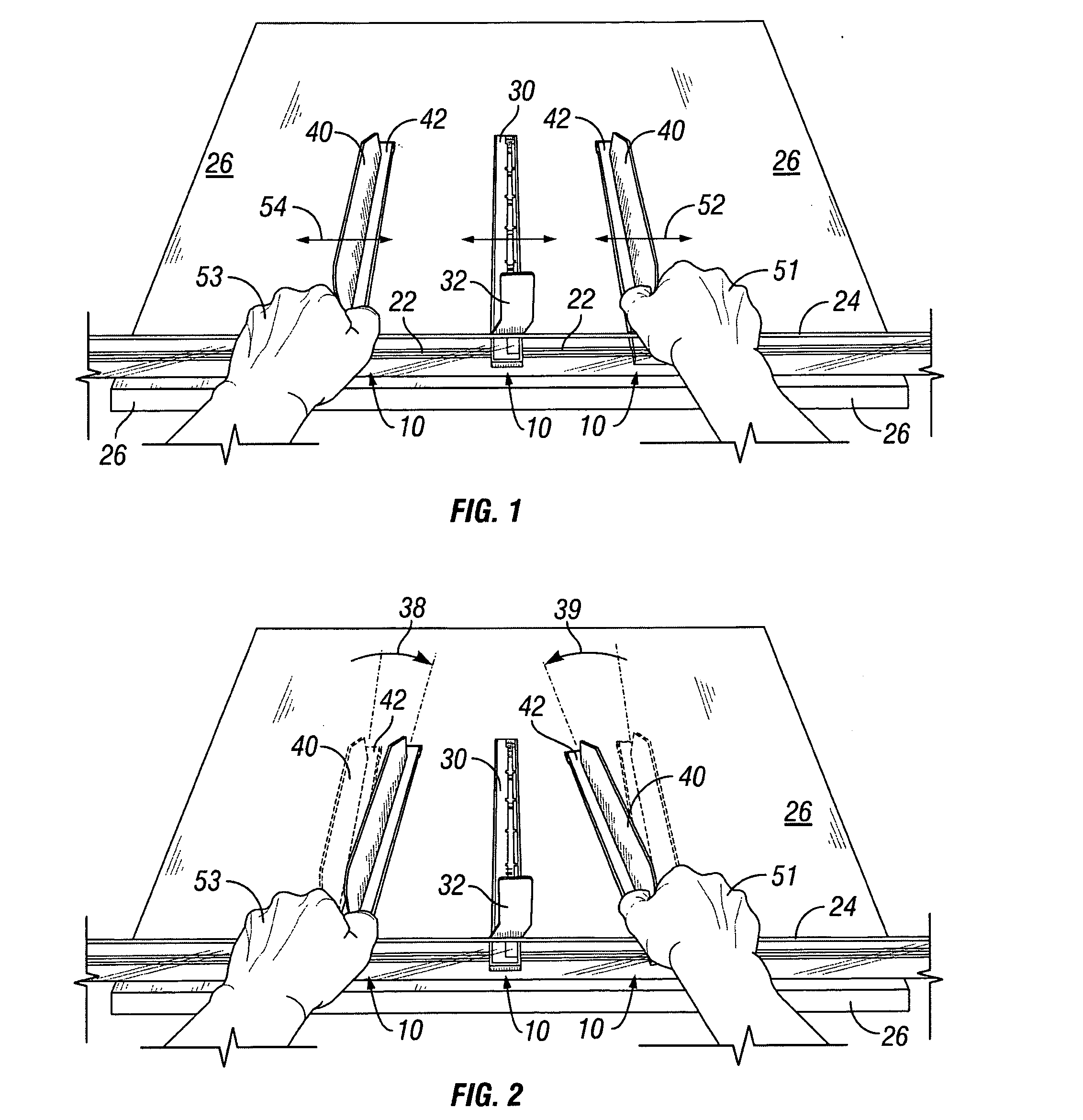

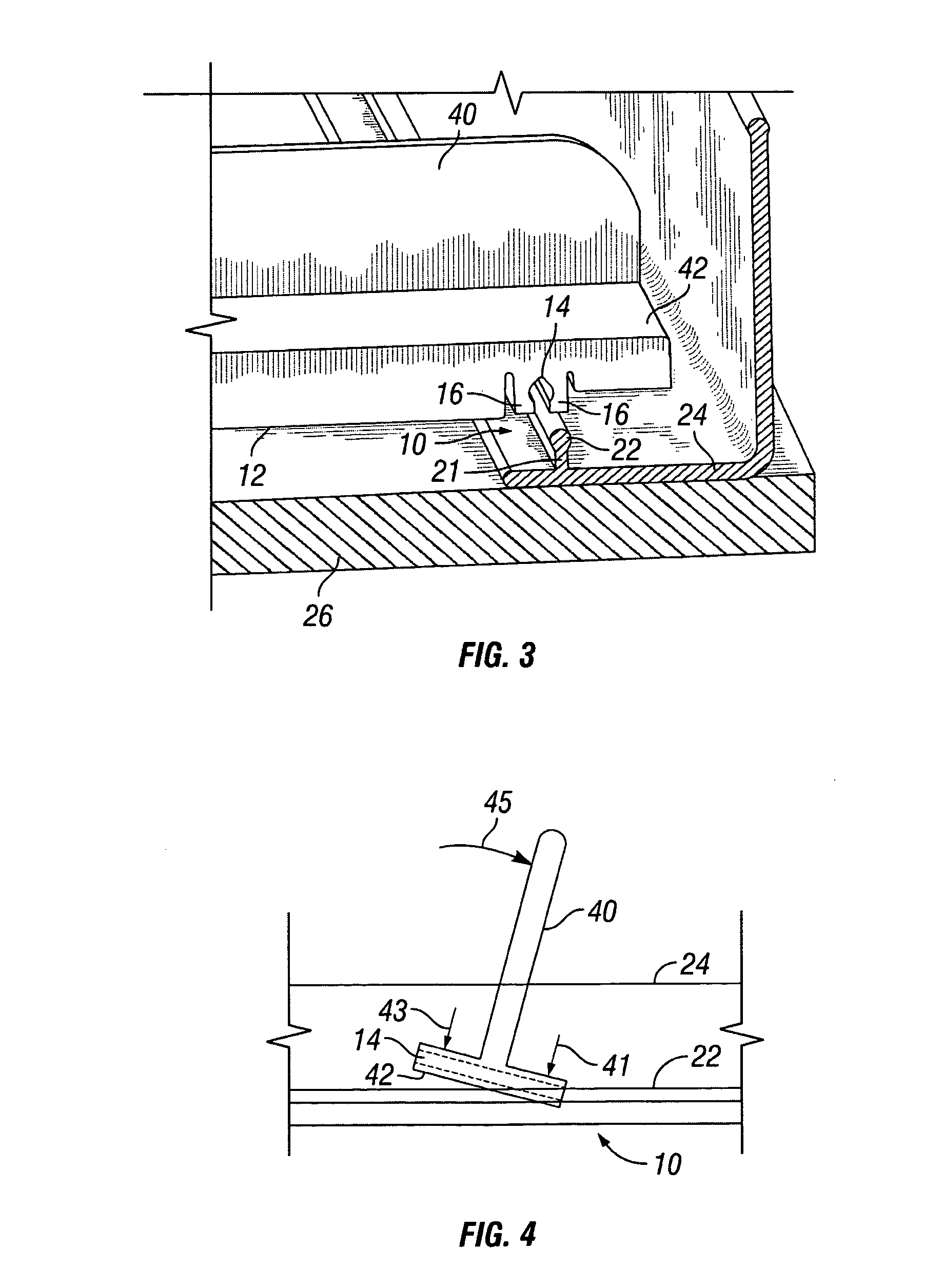

[0021] One embodiment of the present invention is shown in the attached drawings. It should be understood that the self-fronting merchandise system may be configured in various manners that all serve the purpose of the invention. The primary purpose of the invention is to save time and labor in adjusting rows of merchandise on store gondola shelves. The apparatus of the present invention allows movement of divider walls and pusher tracks into a desired alignment along the shelf without requiring removal of merchandise managed by these devices, while preventing unwanted movement and misalignment of rows of merchandise that can result from unwanted or inadvertent movement of divider walls and pusher tracks.

[0022] The present invention uses two ways to resist sliding contact in the coupling between the longitudinal members and the elongated coupling element of the shelf-mounting member. The first way is by physical shape: the coupling is designed to cause and rapidly increase physical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com