System and device for heating or cooling shape memory surgical devices

a technology of shape memory and surgical devices, applied in the field of system and device for heating or cooling nickel/titanium alloy implant clamps, can solve the problems of many prior art devices not including reliable safety systems, many prior art devices to be manufactured to extremely restrictive specifications,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

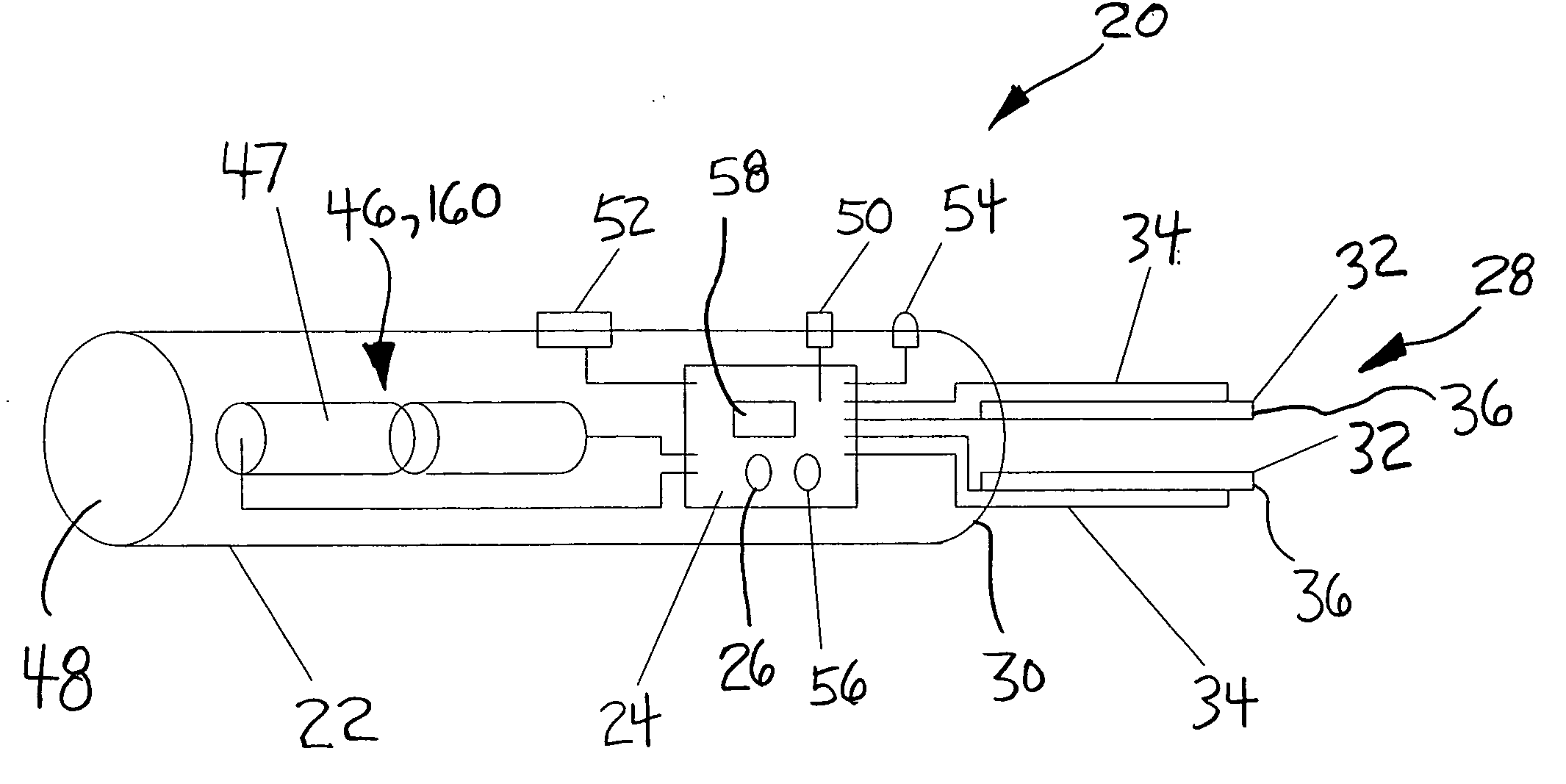

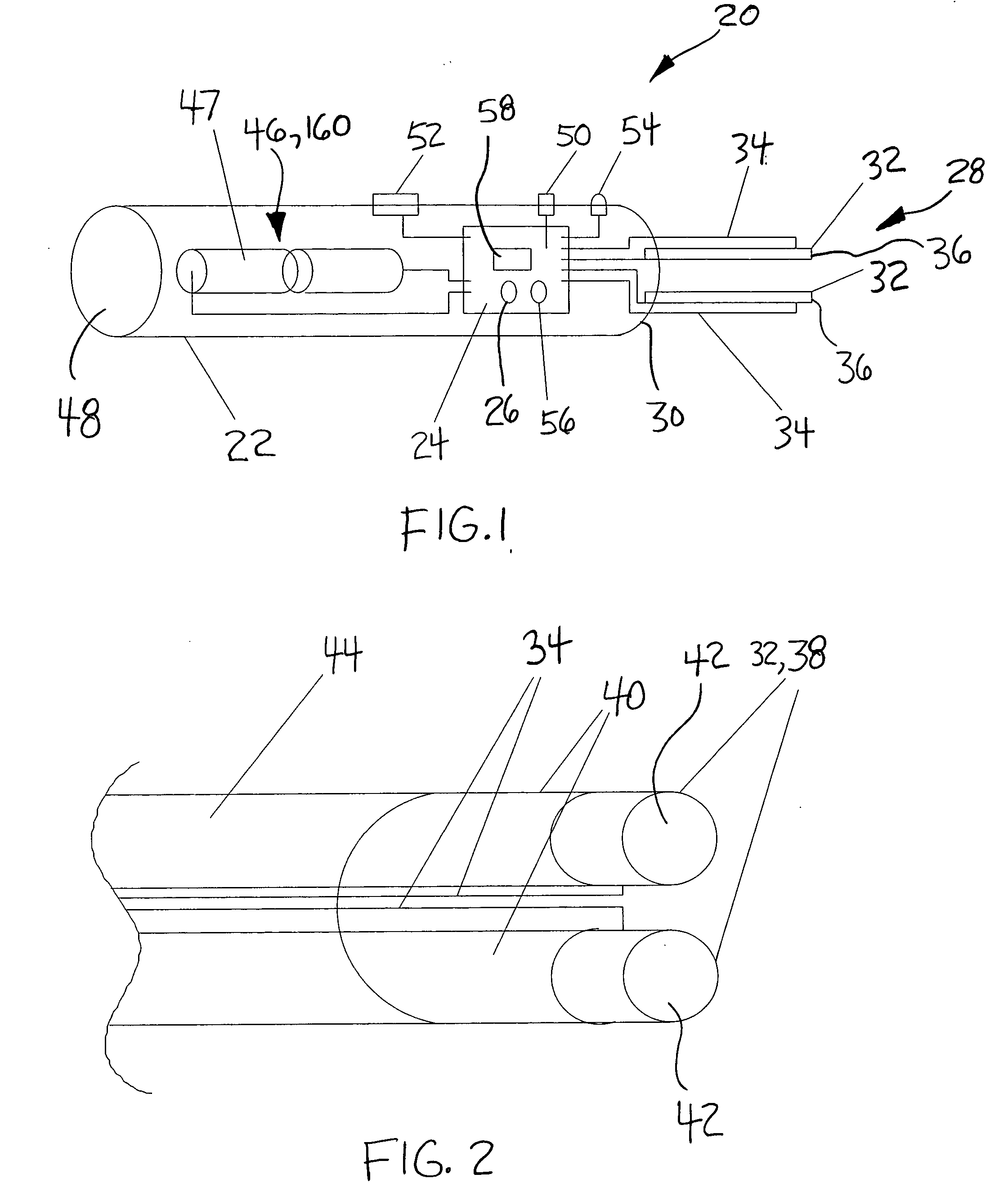

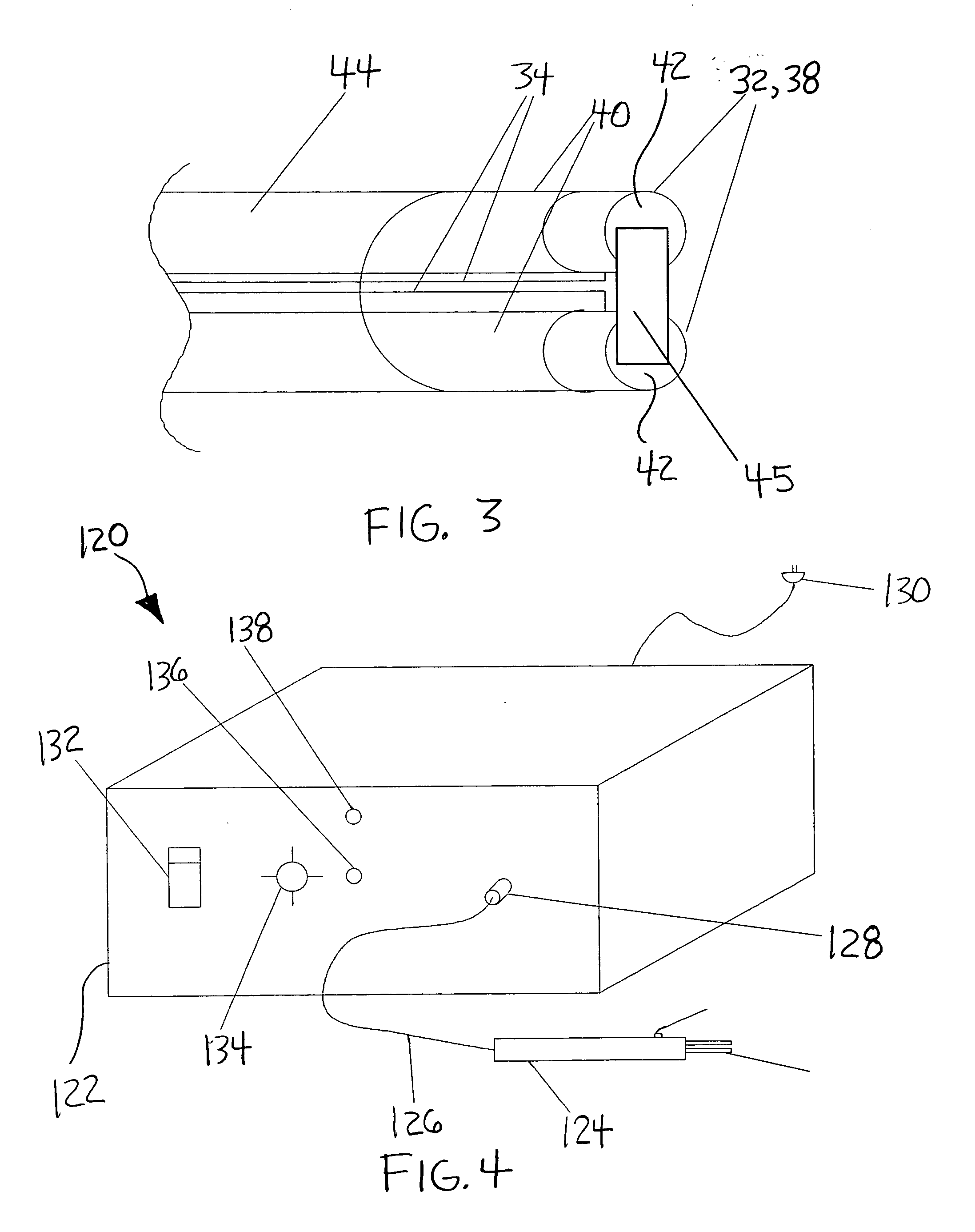

[0016] Referring now to the drawings in which like reference numerals indicate like parts, and in particular, to FIG. 1, one aspect of the present invention is a system 20 for heating a heat-transformable shape memory surgical device (not shown). As illustrated in FIG. 1, in one embodiment, system 20 is contained in a sealed, sterilizable handheld housing 22. System 20 includes a printed circuit board 24 including a system controller 26, both of which are contained in housing 22. System controller 26 is connected with a thermal probe 28, which extends from housing 22, for heating the shape memory surgical device.

[0017] Housing 22 is generally sealed such that it is sterilizable and can withstand the conditions of an autoclave without damaging any of its internal components such as system controller 26. The components of system 20 generally form a handheld device in the form of housing 22.

[0018] Thermal probe 28, which is used to heat the shape memory surgical device, is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com